Delta P, Inc. a Philippine-based power provider signed a 15-year Power Supply Agreement (PSA) with the Palawan Electric Cooperative (PALECO). The agreement meant that Delta P needed to build a power plant with an output of at least 26.65 MW to the main Palawan grid. Wärtsilä provided an EPC solution (engineering, procurement and construction) for

a relocation project.

“Our best option, as it were, was to build a plant with relocated engines. We could not get a better company to do this than Wärtsilä, who originally manufactured them,” says Mark Ferrer, Project Manager at Gigawatt Power Inc. In 2007 Delta P was acquired by a joint venture between Gigawatt Power, Inc. and Vivant Energy Corporation (a subsidiary of Vivant Corporation). Gigawatt Power, based in the Philippines, owns and operates both conventional and renewable power plants through its subsidiaries.

The power demand on the island of Palawan, Philippines is ever increasing. The Power distribution company (PALECO) at Palawan requested offers from power producers to provide additional power. “Our unsolicited proposal was accepted thru a so-called Swiss Challenge, and we had to look for an EPC contractor for this relocation project”, says Mr. Ferrer.

Wärtsilä was awarded total responsibility

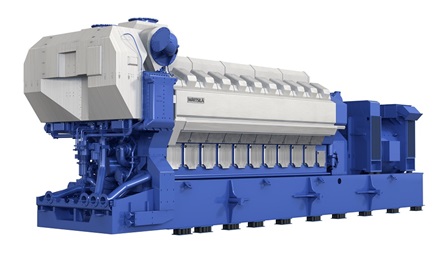

Wärtsilä provided a solution to build a 30 MW power plant based on relocated equipment consisting of four Wärtsilä 18V32 generating sets including auxiliaries. The relocation project was offered on an EPC basis, meeting contractual obligations such as a guaranteed completion date and performance guarantees.

– Wärtsilä and Delta P Inc have been working hand in hand for decades, and most of our previous major repairs and maintenance activities have been handled by the company. We chose Wärtsilä for the relocation EPC-project because we would get a single vendor to carry out the overhauls, the whole installation, and commissioning, which gives us cost savings compared to an entirely new plant, says Mr. Ferrer.

Wärtsilä’s wide-ranging delivery comprised engineering, EPC installation, including civil works and commissioning of the power plant, and inspection, overhaul and upgrade of four Wärtsilä 18V32 engines and auxiliaries, including parts supply. In addition, each generating set went through a performance test to ensure that the performance guarantees stipulated in the contract were achieved. Furthermore, the heating systems were converted from steam to electric on the auxiliaries.

– Having Wärtsilä take on the EPC for the whole project resulted in savings regarding cost, time and communications. It also meant that we could focus on our core business, says Ferrer.

Construction work and cyclones

Palawan has three independent power producers of which Delta P is one, and the company owns and operates an existing 16 MW diesel-fired power plant in Puerto Princesa, Palawan. The new power plant that will add stability, reliability and flexibility to the grid was built in only 15 months and was completed in April 2017.

Mr Ferrer says that the project went well and according to plan: “Wärtsilä has the template for the design of a power plant for any site requirements. The good cooperation and dedication of both Wärtsilä and the Delta P project management team helped this project become a success.”

Wärtsilä as a team performed well, but there is no such thing as a 100% perfect project.

– The unexpected long heavy rainy season and the cyclones during the construction phase were, however, the biggest challenges we faced. The work even had to be stopped a few times completely. Another challenge was the coordination of logistic activities versus the installation phase since the construction site has limited space for equipment storage. All challenges were overcome with proper planning, scheduling, coordination and timely action from both Wärtsilä and Delta P, says Mr. Ferrer.

Successful EPC project

Despite this being the first EPC relocation project for Wärtsilä Services, the result was a success in many ways. Proper planning, effective communication and close monitoring and control of the project progress and project activities were of vital importance in this project.

It is worth mentioning that during the whole project execution phase no lost time incidents (LTI) were recorded. For this exemplary safety culture Delta P presented a safety award to Wärtsilä’s team, says Mr. Ferrer.

According to Mr. Ferrer, the commissioning of the plant is still ongoing to reach full capacity. Safety inspections and re-adjustments to grid settings are being made.

– Since the engines are not new and this is a relocation project, we were prepared for possible technical challenges. Wärtsilä has, however, demonstrated excellent flexibility and we are still relying on their support for engineering and technical maintenance and spare parts.

The relocation project was successfully completed within the agreed time frame. Thanks to this, the customer can achieve his set targets with their customer, the Power Grid Company.

– With all the results from this project at hand, I would recommend other plant owners with similar needs to contract Wärtsilä for this type of project, because Wärtsilä has the design and engineering capabilities worldwide and can provide best practices solutions, concludes Mr. Mark Ferrer.