With the acquisition of the Dutch underwater solutions specialist Trident BV, Wärtsilä will now be able to perform maintenance and repair services under water, providing a better service portfolio for its customers, resulting in minimal downtime – and enabling operators to avoid the potential loss of income of having to bring a vessel into dry dock.

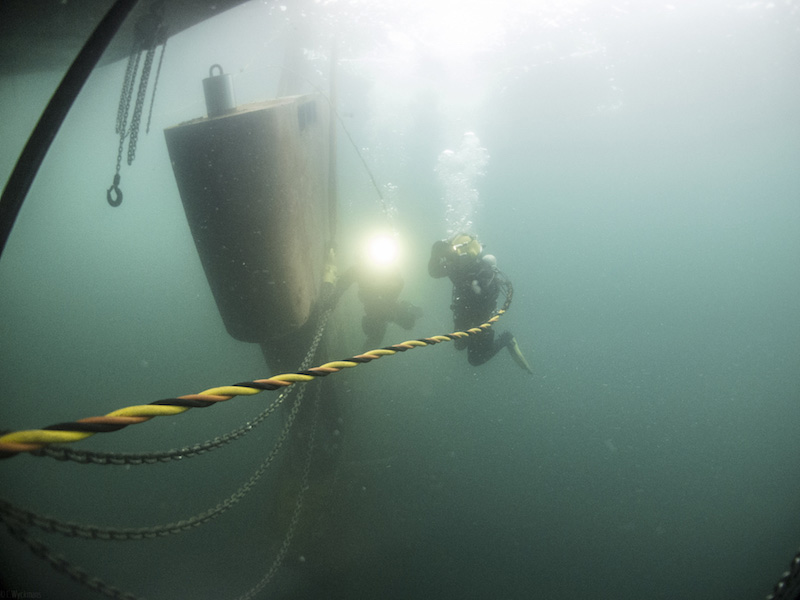

The acquisition of Trident will enable Wärtsilä to become the first Original Equipment Manufacturer with a global underwater services footprint. Trident’s offering includes underwater repair, overhaul of propulsion systems, and regular maintenance such as hull cleaning and propeller polishing. It also carries out wet welding repairs, providing an equivalent level of quality to what would be delivered in dry environment and certified by the major classification societies, as well as cofferdam repair, which allows for permanent shell plate repairs while afloat. Trident is known for executing fast, reliable and complex repairs under water.

Trident was established in 1993 when commercial diver Adrie Huijbregts took the plunge and set up his own underwater repair and maintenance firm. Since then, the company has gone from strength to strength, creating an unrivalled reputation as the number one provider of highly skilled underwater services. As a result of its excellent track record, Trident’s repairs are typically covered by the warranty of the OEMs with which it partners.

The acquisition of Trident will enable Wärtsilä to become the first Original Equipment Manufacturer with a global underwater services footprint.

Total, global service and maintenance

Fast-forward to 2018 and Trident has been acquired by Wärtsilä. Together, the two companies will be uniquely positioned to offer marine service and maintenance, wherever and whenever it is needed, regardless of whether a vessel is on land or at sea.

“Trident will add another string to Wärtsilä’s bow. Going forward, we will work closely with engineering colleagues in Wärtsilä to support them in product design to allow for easy underwater maintenance,” says Huijbregts, who will remain with Trident under the Wärtsilä umbrella in an advisory role.

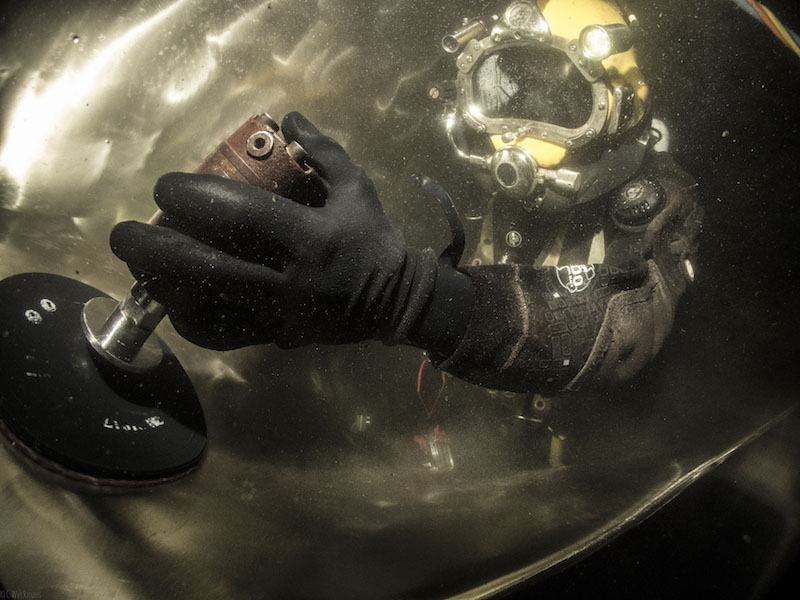

Over the past decade, Trident has created an internal, innovative brain trust as a means to transform ideas into reality.

It has resulted in new industry standards for servicing (propulsion) equipment below the waterline. An example is the award winning “FLEX-DAM” hyperbaric habitat for shaft seal replacement on main propulsion shaft lines.

Trident serves customers, around the world, by using its fully equipped workshops and certified personnel in the Netherlands, Italy, and Canary Islands. Going forward, its state-of-the-art equipment and expertise will be combined with Wärtsilä’s global presence.

“No vessel will ever be far from one of our specialist underwater teams, should a situation arise that requires their assistance,” says Trident’s Managing Director, William Winters.

Trident is known for executing fast, reliable and complex repairs under water.

Complex underwater operations

Trident’s offering extends far beyond standard underwater cleaning and maintenance services. In November last year, it carried out a full underwater exchange of stabiliser fin weighing more than 20 metric tons on behalf of the cruise company AIDA Cruises.

“This was the first time that a stabiliser fin had been exchanged without taking the vessel out of service,” explains Winters. “The alternative would have been to take the ship to dry dock and lose the income for the cruise, or to wait for the next scheduled dry docking, which was several years down the line.”

In another recent case, Trident removed and reinstalled a rudder weighing 30 metric tonnes on a fully loaded bulk carrier in Stavanger, Norway.

“Operations such as these are not inexpensive, but, when a vessel operator has to take its ship out of service and put it in dry dock due to an unplanned stoppage, the potential loss of income is astronomical,” continues Winters. “Now that we know we can carry out complex overhauls under water, it will change the nature of vessel repairs and maintenance.”

Clean hull for enhanced fuel efficiency

Going forward, there are further plans to integrate Trident’s services with the cutting-edge innovations from Wärtsilä’s digital portfolio. For example, the combination of its hull-cleaning services with Eniram’s analytics

will allow for maximum fuel savings through optimised hull cleaning cycles.

“A clean, friction-free hull is key to maximising the fuel efficiency of a vessel as she glides through the water. With Eniram’s sensors, the vessel

will tell us when its hull needs cleaning, allowing us to carry out the service at the most opportune moment, without disrupting the operation of the ship,” explains Huijbregts.

Last but not the least, Trident is also in the process of developing an environmentally sound method for underwater hull cleaning. The new process will make it possible to remove fouling from the ship’s hull and safely bring it up to the surface, after which a filtering process allows the water back into the environment without releasing any contamination. This sustainable hull cleaning service will be the first of its kind in the market, and, unlike other available solutions, can cover close to 100 per cent of the submerged hull.

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.