Wärtsilä Gas Solutions offers a range of regasification technologies

To use liquified natural gas (LNG) for purposes like fuel, power generation, heating and cooking, the LNG must be converted back to its gaseous state. This process is known as regasification, and typically takes place where LNG carriers discharge their cargo.

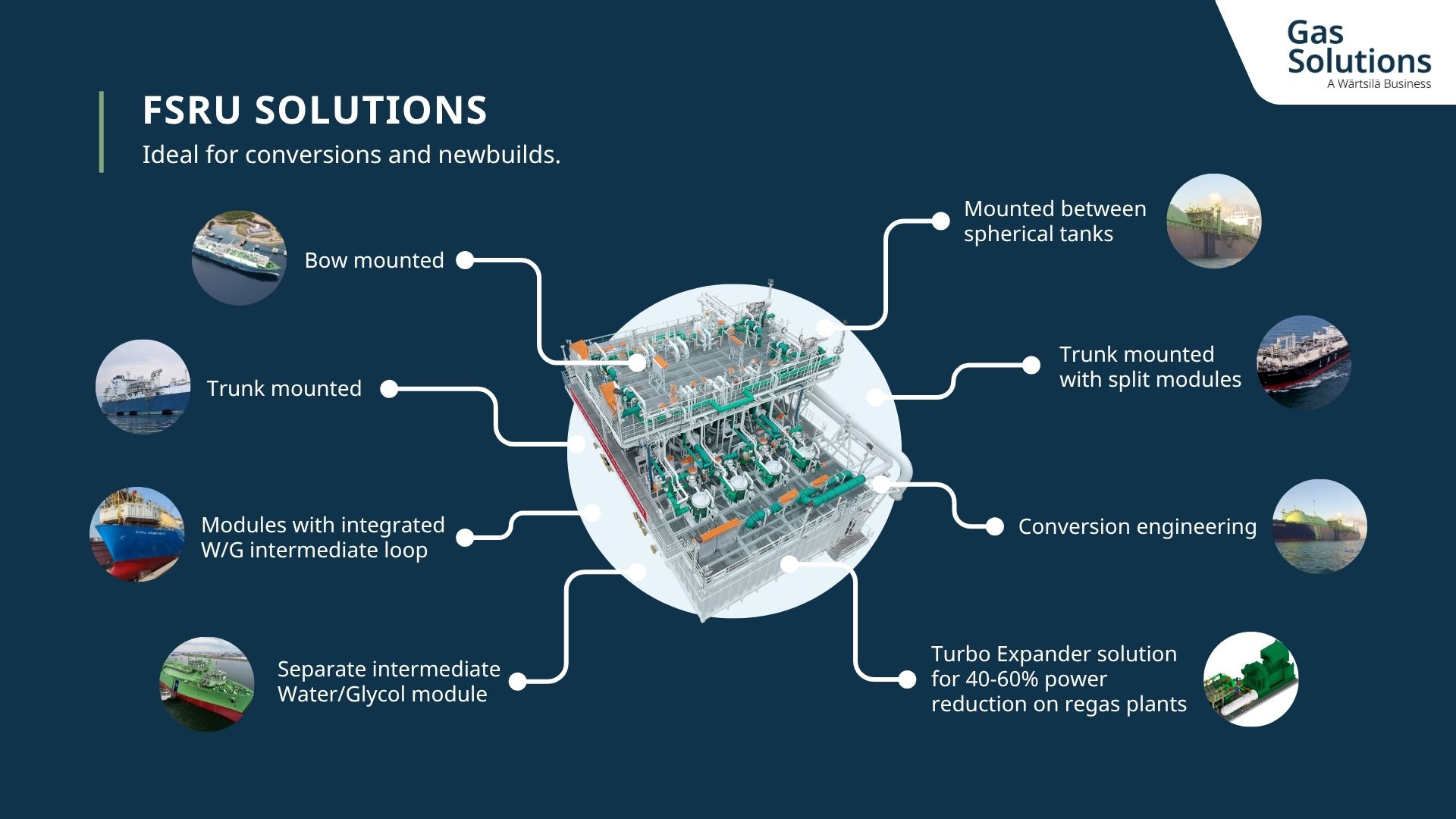

Wärtsilä Gas Solutions offers a range of regasification technologies for floating storage regasification units (FSRUs), barges, jetties, and onshore terminals. Our portfolio represents an industry benchmark in terms of energy efficiency, robustness, and operational flexibility.

Our track record includes delivery and commissioning of numerous floating LNG regasification plants based on either closed loop regasification technology, using steam with water/glycol as the intermediate heating medium. We do open loop systems using seawater with water glycol as the intermediate heating medium. In FSRU projects, Wärtsilä also offers engineering for the complete conversion – including integration of regasification modules like BOG compressors and power module, along with all the other systems for cargo handling, upgrading and utilities.

Our modularised regasification plants for jetty installations facilitate a much shorter construction time compared to conventional land-based terminals.

Technical data

- Wärtsilä Gas Solutions' regasification units are available either as multi-skid deliveries, or as complete turnkey and single-lift topside modules

- Train size: 50 mmscfd up to 280 mmscfd. Higher capacities with multiple trains

- Delivery pressure: Designs from 5 to 125 bar possible

- Temperature NG outlet: Typically, 5 C below seawater temperature

- Example module size: 3x250 mmscfd, 25x18x12m, 700 tons

Applications

- FSRU’s (LNG Carriers)

- Barges

- Jetties

- Onshore terminals

Key benefits

- Supplied by a market leader with extensive reference list

- Fast delivery (12-16 months)

- Compact and reliable plant

- Modularized delivery (easy installation)

- Flexible plant configuration

- Easy operation and maintenance

- Quick ramp up/down

Press releases

Wärtsilä to supply re-gasification system for Norwegian ship conversion

Wärtsilä has been contracted to supply the re-gasification system for an FSRU (Floating, Storage, Re-gasification Unit) conversion project that Höegh LNG plans to carry out on a modern LNG vessel. The contract was signed in August.

The Wärtsilä re-gasification system to be supplied will feature regas technology using water glycol as the intermediate medium instead of propane. This provides a more compact solution being some 15 percent smaller and lighter than the propane based system.

“We have enjoyed a good relationship with the customer for many years and have supplied them with a number of regas systems. Repeat orders are the most positive endorsement of customer satisfaction, and we are delighted to again be the supplier of choice for this conversion project,” says Timo Koponen, Vice President, Flow & Gas Solutions, Wärtsilä Marine Solutions.

“Having used Wärtsilä’s systems for previous FSRUs, we are familiar with their expertise in this field and we did not hesitate in accepting their competitive bid and selecting their system for this FSRU conversion vessel,” says Sveinung J.S. Støhle, CEO and President of Höegh LNG.

The Wärtsilä scope of supply for this project comprises the water glycol re-gasification module, the water glycol /seawater heaters and pumps. Delivery is scheduled for autumn 2017.

Wärtsilä has previously supplied eight re-gasification systems to Höegh LNG.

Link to more information on wartsila.com

Wärtsilä LNG Regasification

Link to image

Caption: Wärtsilä will supply the re-gasification system for an FSRU conversion project that Höegh LNG plans to carry out on a modern LNG vessel.

Media contacts:

Mr Reidar Strande

General Manager, LNG

Wärtsilä Marine Solutions

Tel: +47 9099 7454

reidar.strande@wartsila.com

Ms Marit Holmlund-Sund

Senior Manager Marketing, Communications, Marine Solutions

Wärtsilä Corporation

Tel: +358 10 709 1439

marit.holmlund-sund@wartsila.com

Wärtsilä in brief:

Wärtsilä is a global leader in advanced technologies and complete lifecycle solutions for the marine and energy markets. By emphasising sustainable innovation and total efficiency, Wärtsilä maximises the environmental and economic performance of the vessels and power plants of its customers.

In 2015, Wärtsilä's net sales totalled EUR 5 billion with approximately 18,800 employees. The company has operations in over 200 locations in more than 70 countries around the world. Wärtsilä is listed on Nasdaq Helsinki.

www.wartsila.com