Wärtsilä Gas Solutions offers a range of regasification technologies

To use liquified natural gas (LNG) for purposes like fuel, power generation, heating and cooking, the LNG must be converted back to its gaseous state. This process is known as regasification, and typically takes place where LNG carriers discharge their cargo.

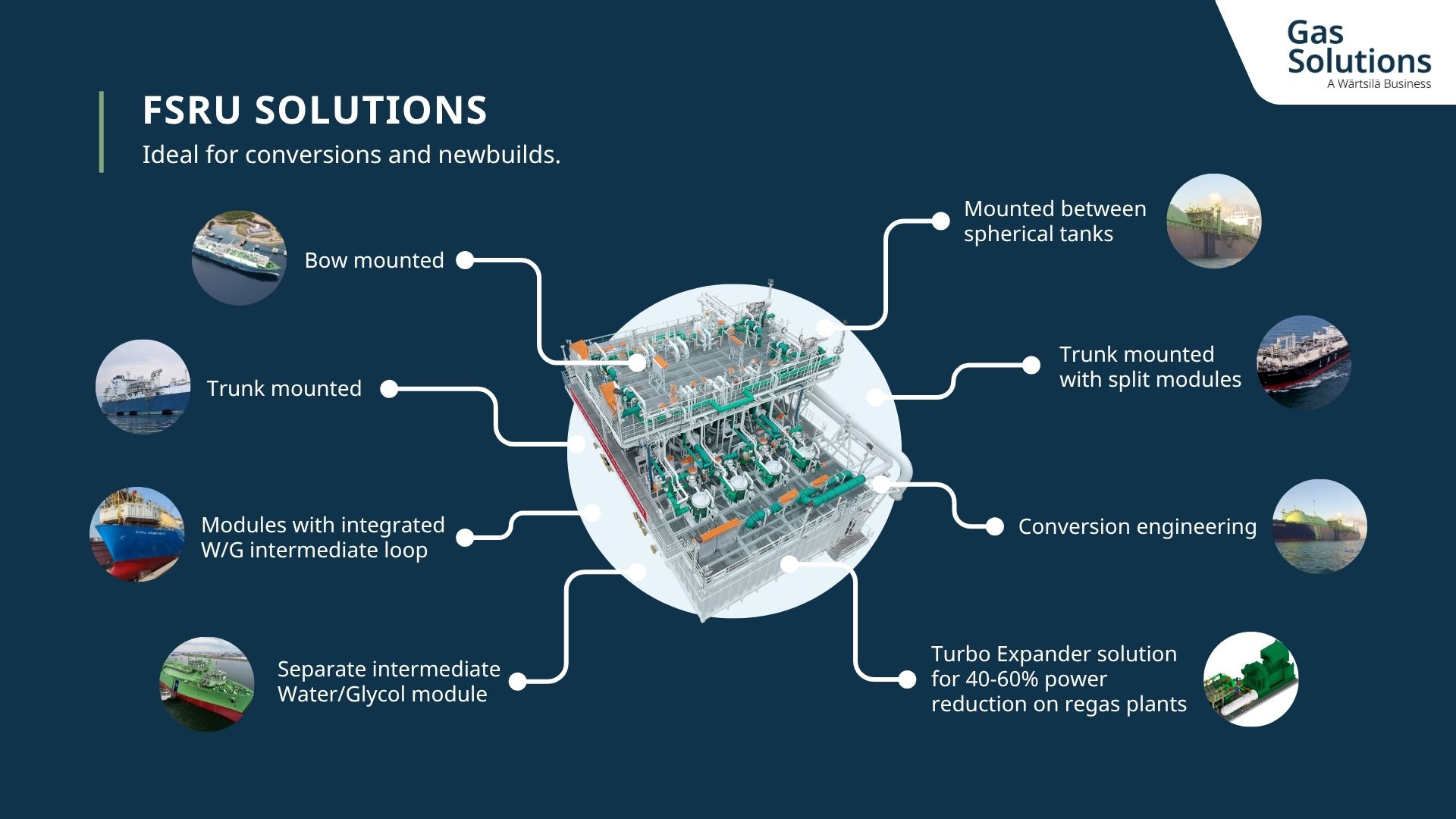

Wärtsilä Gas Solutions offers a range of regasification technologies for floating storage regasification units (FSRUs), barges, jetties, and onshore terminals. Our portfolio represents an industry benchmark in terms of energy efficiency, robustness, and operational flexibility.

Our track record includes delivery and commissioning of numerous floating LNG regasification plants based on either closed loop regasification technology, using steam with water/glycol as the intermediate heating medium. We do open loop systems using seawater with water glycol as the intermediate heating medium. In FSRU projects, Wärtsilä also offers engineering for the complete conversion – including integration of regasification modules like BOG compressors and power module, along with all the other systems for cargo handling, upgrading and utilities.

Our modularised regasification plants for jetty installations facilitate a much shorter construction time compared to conventional land-based terminals.

Technical data

- Wärtsilä Gas Solutions' regasification units are available either as multi-skid deliveries, or as complete turnkey and single-lift topside modules

- Train size: 50 mmscfd up to 280 mmscfd. Higher capacities with multiple trains

- Delivery pressure: Designs from 5 to 125 bar possible

- Temperature NG outlet: Typically, 5 C below seawater temperature

- Example module size: 3x250 mmscfd, 25x18x12m, 700 tons

Applications

- FSRU’s (LNG Carriers)

- Barges

- Jetties

- Onshore terminals

Key benefits

- Supplied by a market leader with extensive reference list

- Fast delivery (12-16 months)

- Compact and reliable plant

- Modularized delivery (easy installation)

- Flexible plant configuration

- Easy operation and maintenance

- Quick ramp up/down