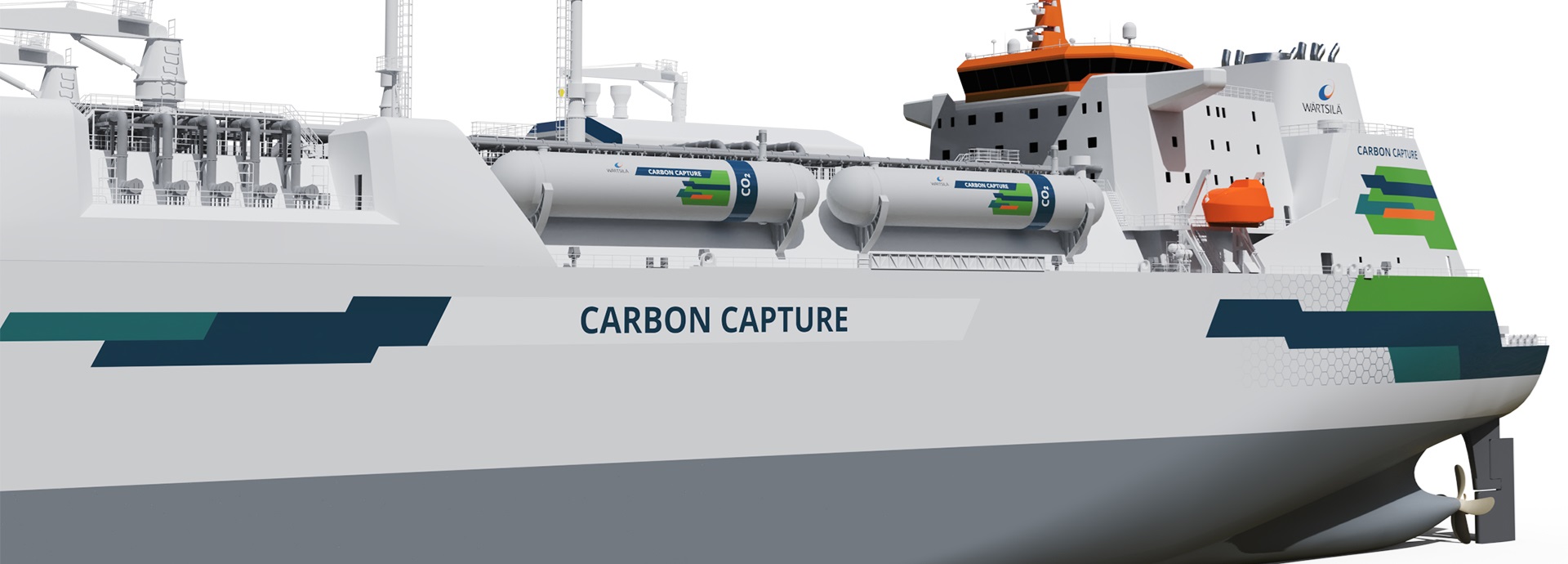

Onboard carbon capture and storage CCS

Decarbonisation can be achieved in three ways: burning less fuel, cleaning up emissions, and using alternative energy sources. Carbon capture technology is a powerful method for cleaning up emissions.

Watch the video to learn how carbon capture could help shipowners meet their CO2 targets.

Wärtsilä carbon capture solution – how does it work?

Carbon capture is a method of capturing CO2 from fossil fuel after it is combusted in an engine, before it is released into the atmosphere. Wärtsilä has developed an industry-first full-scale onboard carbon capture system which has the potential to reduce a vessel’s CO2 emissions by up to 70%.

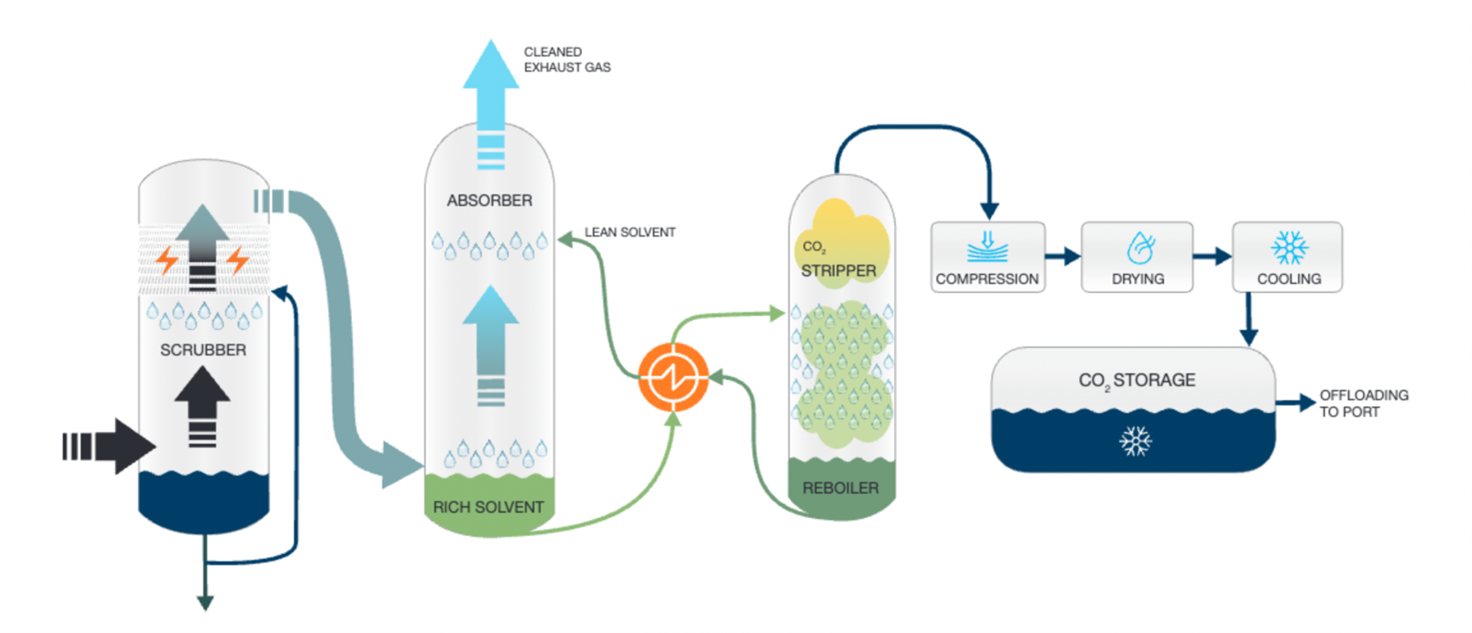

The Wärtsilä carbon capture solution works in five main stages: pre-conditioning, absorption, desorption (or stripping), liquefaction and storage.

In pre-conditioning – depending on the fuel, the exhaust gas is cleaned of NOx, SOx and particulate matter and cooled down.

In the second stage, the exhaust gas is mixed with a liquid solvent. This captures the CO2 in the solvent. The cleaned exhaust gas exits the system.

In the stripping stage, the CO2-saturated solvent is heated which releases the CO2. The lean solvent will be reused in the system.

In the liquefaction stage, the CO2 is compressed, dried and cooled down to liquid form for storage.

The final stage is storage. The liquid CO2 is pumped through pipes to onboard tank(s), where it is stored until it can be offloaded.

Technology proven in the world-first maritime pilot

Clipper Eris, an ethylene carrier operated by the Norwegian Solvang Shipping is sailing with an onboard CCS system in the world-first full-scale maritime pilot.

This pioneering pilot has proven the technical viability of the Wärtsilä carbon capture solution. The pilot also tests how this technology can be integrated with land-based CCS infrastructure.

Who can benefit from onboard carbon capture?

Carbon capture technology from Wärtsilä is available as a retrofit and newbuild solution for any type of vessel. The following types of vessels will find it particularly interesting:

- Tankers

- LNG carriers

- Offshore vessels

- Bulkers

- Merchant vessels.

CCS-ready scrubbers as a first step

You can start your journey to carbon capture with a smaller step: adopting a CCS-ready scrubber from Wärtsilä.

When your vessel has a CCS-ready scrubber from Wärtsilä already installed, you have taken the first step towards carbon capture. Thanks to the CCS-ready scrubber, your vessel will comply with SOx emissions regulations right away. The configuration can also be built on to tackle particulate matter and NOx emissions and even filter microplastics.

In short, adopting a CCS-ready scrubber paves the way for a smooth CCS system adoption in the future.

Why carbon capture?

Carbon capture technology complements other emissions reduction technologies, forming part of a comprehensive decarbonisation strategy.

Before alternative fuels become available at scale, installing a carbon capture system can ensure compliance with mid-term IMO targets while still sailing on fuels that are widely available.

Why Carbon capture solution from Wärtsilä?

Wärtsilä is the market-leader in marine exhaust gas cleaning systems and offers integrated solutions for all types of ships.

We have developed onboard carbon capture technology for many years, and our solution is proven to capture up to 70% of CO2 emissions from ship engines. This is a practical near-term solution for reducing your vessel’s CO2 emissions.

The Carbon capture solution from Wärtsilä builds on our long-time experience and expertise in exhaust treatment systems. For example, adopting our CCS-ready scrubber will ensure compliance with SOx regulations and in addition, pave the way for a smooth CCS system adoption in the future.

Interesting insights on exhaust treatment

Discover these insightful articles – they will build your knowledge of exhaust treatment solutions

Hand-picked press releases

Reach out to Wärtsilä to discover how our carbon capture solution could help ensure your vessel’s compliance.