Wärtsilä Investor Relations organised a site visit to the Central Distribution Centre Kampen (CDC) in the Netherlands on March 27. This event, aimed at investors and analysts, provided a comprehensive overview of Wärtsilä's future growth prospects in the Services business, and allowed the guests to witness firsthand the operational efficiency and sustainability in logistics.

The presentation material from the event can be found here.

Services is a key driver for Wärtsilä growth and profitability

The event commenced with a presentation by Stefan Wiik, Vice President, Parts and Field Service, who showcased the impressive growth of our services business over the past years, emphasising its significance for Wärtsilä’s overall growth and profitability. In 2024, services grew by 9% compared to the previous year, and approximately 40% compared to 2021. The main drivers of this growth include an expanding installed base, climbing the service value ladder, retrofits, and upgrades.

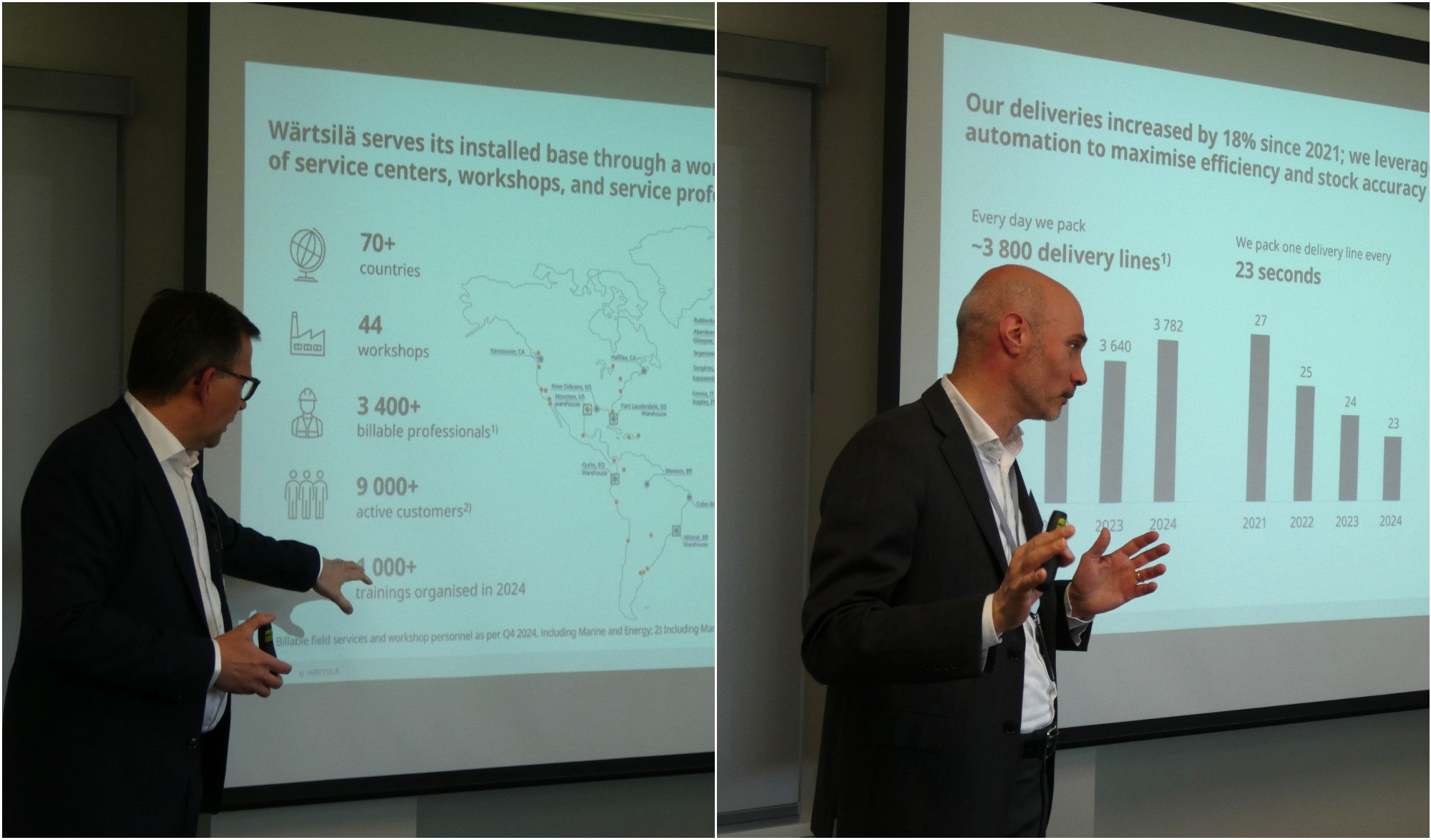

The Parts and Field Service team in Wärtsilä supports all our service delivery models, including agreements and retrofits. Wärtsilä’s installed base is served through a world leading global network of service centers, workshops, and service professionals in 70+ countries. Marine and Energy have approximately 3,400 billable professionals around the globe serving the company’s ~ 9,000 active customers.

Operational efficiency and sustainability as the main factor behind the Wärtsilä Global Logistics Services’ success

Wärtsilä Global Logistics Services (WGLS) plays a fundamental role in Wärtsilä’s service strategy by providing spare parts logistics to Marine and Energy customers worldwide. Gianluca Bertossi, Head of Global Parts Management and Supply Management, presented insights and key figures to Wärtsilä’s spare part business before the visitors could have a tour around the impressive logistic centre that covers a surface of 37,000 m2.

Packing approximately 3,800 delivery lines every day, one every 23 seconds, requires organisation, planning, and efficiency, something that was clearly visible to the visitors in the warehouse. These volumes are possible thanks to CDC automation, which in 2024 handed 97% of all pickings at this site. Automation is not only crucial for maximizing efficiency and speed in the process but also bringing reliability, granting a stock accuracy of 99,9%.

Wärtsilä's continuous improvement mindset is evident also in WGLS. On-time delivery has improved by 18% since 2021, being today at 89%. To the question of what it would take to get the on-time delivery to 100%, Gianluca commented that even though planning is crucial, the delays are mostly due to external factors such as disruptions in shipping routes or challenges in customs.

Wärtsilä Global Logistics Services delivers high-quality services through a seamlessly integrated supply chain that is very focused on sustainability. WGLS in Kampen uses eco-friendly packaging and has achieved a 67% reduction in plastic use since 2022, equivalent to approximately 35 tons per year. Additionally, all domestic truck transport in Kampen uses HVO100 fuel, reducing CO2 emissions by 90%, equivalent to around 900 trucks per year.

"Sustainability is a key value for us, and we work closely with our partners and suppliers on it. Today our sustainability impact goes beyond Wärtsilä and our direct customers and suppliers as our suppliers are proposing the same actions to their other customers. It’s a domino effect and something we are extremely proud of," said Gianluca.

The day concluded with an extensive tour to the warehouse led by Kim Björknäs, General Manager, Parts Delivery, WGLS. The visitors could see the operations from inbound to the delivery of the parts and everything in between and get proof point to what they had heard during the presentations.

The investor site visit to Kampen provided a clear picture of Wärtsilä's strategic direction and operational excellence. With a strong focus on growth, efficiency, and sustainability, Wärtsilä is well-positioned to continue delivering value to its customers and stakeholders. The visit underscored Wärtsilä's commitment to innovation and excellence in the Marine and Energy sectors, setting a solid foundation for future success.

Q&A

Marine Service has grown quite rapidly over the years. What kind of a growth rate can we expect going forward?

On March 31 Wärtsilä announced new financial targets, including combined target of 5% annual organic growth for Marine and Energy. For service, we haven’t disclosed any separate target. Services is one of the key drivers for the company’s net sales growth.

Growing installed base is supporting our service growth. Moving up the service value ladder has the potential to increase sales EUR/kW by 2–3x relative to transactional.

You mentioned that you can make 2-3 times more business with agreement customers in Marine. Why is that? What kind of business you do more with them?

As customers move up the service ladder, services become more proactive, integrated, and value-driven, encompassing predictive maintenance, optimization, and comprehensive lifecycle solutions. By using real-time data and advanced analytics to monitor the equipment we predict potential issues before they occur, and therefore minimize downtime and reduce operational costs, delivering significant value to customers.

What are the most common spare parts you sell?

All the power line spares, such as fuel injection, cylinder heads, valves, bearings, pistons, piston rings, and liners, as well as turbocharger spares and automation spare parts, are among our best sellers.

How does Wärtsilä’s service offering differ from its competitors?

Wärtsilä stand out from competitors due to our good spare part availability, widest in-house service network and our comprehensive range of solutions.

How much of your R&D investments are going to service?

Wärtsilä invests ~4% of net sales in R&D to accelerate the development of decarbonisation-related technologies. There are strong R&D synergies between marine and energy, but also between new equipment and service, as we only service equipment manufactured by ourselves.

We have not disclosed the level of R&D investment in service, and in fact, it is reasonably hard to calculate due to the close development and synergies between equipment and service.