In a hurry? Here are the 6 key takeaways

- Methane slip is a significant challenge for LNG-fuelled vessels – but advanced technologies like NextDF from Wärtsilä can now reduce it to less than 1% of fuel use on average for 4-stroke engines.

- Although measuring methane slip is complex, Wärtsilä is contributing to the development of accurate, standardised protocols.

- Retrofit solutions can cut methane slip by up to 75% on existing marine engines.

- Hybrid propulsion and engine optimisation strategies can cut methane slip significantly at low loads, such as during port operations and manoeuvring.

- Reducing methane slip lowers the risk of penalties under tightening emissions regulations.

- Vessel designs that promise low methane slip increase confidence among investors and charterers.

Methane slip in marine vessels is the small amount of methane gas that doesn’t burn in the engine and instead ‘slips’ out into the atmosphere. Methane slip is a challenge for vessels that use LNG as fuel, with tightening emissions regulations making it an increasing concern.

Wärtsilä is a leading expert in reducing methane slip, with cutting-edge technologies and proven solutions that have helped to reduce methane slip to record-low levels.

1. How can methane slip be reliably measured?

According to the official IMO guidelines (MEPC.402(83)), the reference method for measuring methane slip onboard is with a portable or fixed flame ionisation detector (FID) equipped with a non-methane cutter (NMC). This method selectively measures methane by oxidising non-methane hydrocarbons, ensuring accurate methane readings in the complex exhaust environment of a vessel. This setup is suitable for both long-term testing on board vessels and research in laboratories and testbeds.

Alternative methods such as Fourier transformation infrared (FTIR) spectroscopy or non-dispersive infrared (NDIR) sensors can also be used, but for reporting purposes these methods should be validated against the FID+NMC method for the specific exhaust composition.

Two other measurement methods are primarily used for research and testing:

- Laser-based sensors – for high-accuracy onboard applications in research or pilot projects.

- Gas chromatography – for research and verification purposes, rather than continuous onboard monitoring.

Measuring methane slip from vessels is challenging, especially during transient operations like bunkering and port manoeuvres. These activities can cause fluctuations in engine load and exhaust composition, increasing the uncertainty of measurement results.

According to the IMO guidelines, emissions should always be measured under stable load conditions. Environmental conditions such as temperature, humidity and pressure can also affect exhaust gas composition and measurement instruments. Methane slip measurement is currently a validation activity, not a continuous monitoring requirement.

The EU has published guidelines for reporting and verifying actual methane slip tank-to-wake emission factors from marine diesel engines. These guidelines fall under the scope of the FuelEU Maritime regulation.

Wärtsilä contributes to the continuous development of standardised measurement protocols and collaborates with research institutions and regulatory bodies to establish reliable and feasible ways to collect and report emissions data.

2. What are the implications of using fossil LNG versus bioLNG on methane slip levels?

Both fossil LNG and bioLNG lead to methane slip when used in marine engines, but the total climate impact of these fuels differs significantly. While methane slip levels are often similar for both, bioLNG generally offers a much lower well-to-wake greenhouse gas footprint compared to fossil LNG. This is because bioLNG is renewable in origin and has lower upstream emissions.

Wärtsilä’s engine technologies are compatible with both fossil LNG and bioLNG. Because we are continually optimising the combustion process in Wärtsilä engines, methane slip is minimised whether fossil LNG or bioLNG is used.

3. Can methane slip be quantified accurately for emissions reporting?

It is possible to measure methane slip continuously on board a vessel, but this kind of monitoring is still relatively rare because it is costly and rather complicated.

Quite often methane slip levels are estimated for reporting using default emission factors provided by regulatory bodies such as the IMO. These default emission factors are approximations, and they can be used when actual certified values are not available. Operators should aim to use real values in reporting whenever they are lower than the default values in order to benefit from lower penalties or higher surpluses.

Engine Load Monitoring (ELM) records how an engine operates over time and is recognised in the FuelEU Maritime regulation as a method to replace default factors with more accurate data from real operations.

ELM allows companies to replace default test‑cycle weighting factors with ELM‑derived, real‑operation weighting factors. These can then be combined with verified methane slip measurements to calculate representative emission values. In this way operators can calculate annual emission values that are more representative than would be possible with generic assumptions.

4. What solutions are available to reduce methane slip in marine engines?

Wärtsilä has many solutions available for reducing methane slip in both newbuilds and existing vessels. Methane slip reductions of up to 75% can be achieved with the right technology.

Wärtsilä’s retrofit solutions to reduce methane slip in existing vessels include:

- Spark Gas (SG) conversion for Wärtsilä 50DF engines

- Converts dual-fuel engines to spark-ignited gas operation

- How: Uses an electrically controlled pre-combustion chamber valve to optimise combustion

- Fuel savings: Up to 4.6%

- Compatibility: Retrofit-ready for Wärtsilä 50DF engines

- Methane slip reduction: Up to 75%, bringing methane emissions down to 1.1% of fuel use - Engine upgrades for Wärtsilä 34DF, 46F-DF and 50DF engines

- Quick to install with minimal downtime

- How: Optimises air-fuel ratio and combustion conditions for each engine type and operating profile. Most upgrades focus on advanced combustion control software, with optional hardware enhancements such as low-crevice technology or turbocharger tuning for greater impact.

- Methane slip reduction: Up to 65% depending on engine type and load.

Wärtsilä solutions to reduce methane slip in newbuilds include:

- NextDF for Wärtsilä 25DF, Wärtsilä 31DF and Wärtsilä 46TS-DF engines

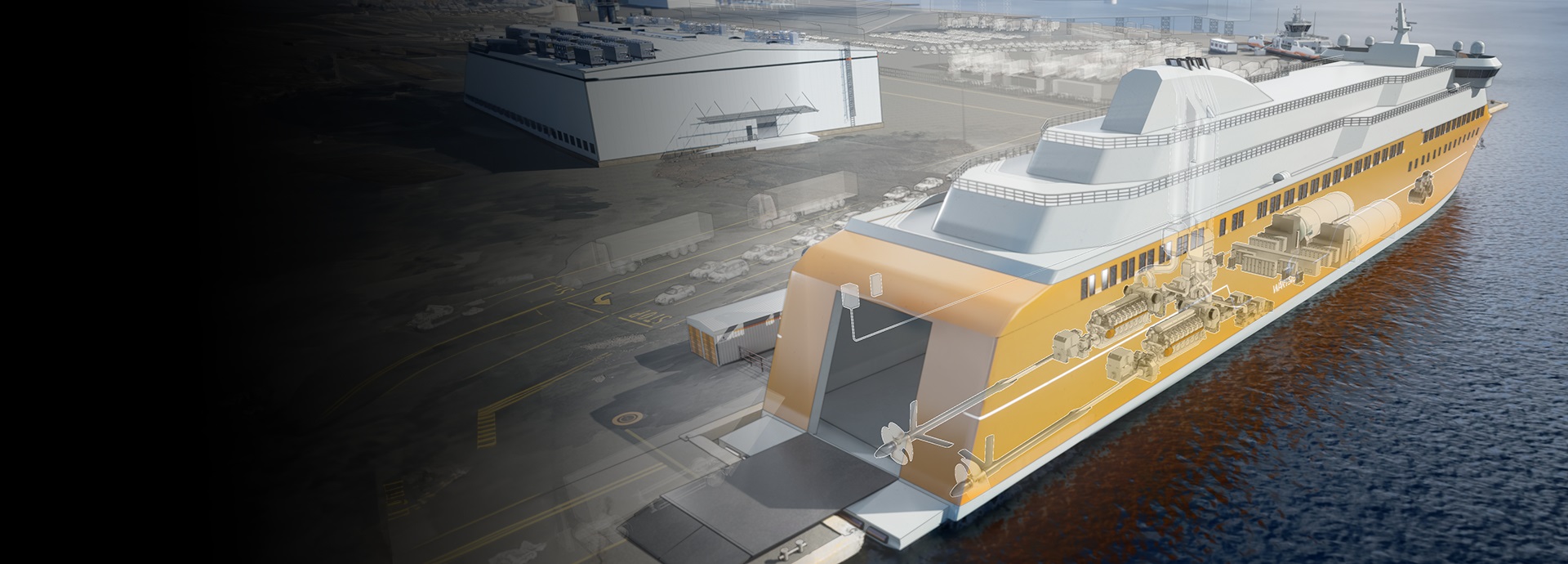

- Already selected for the MSC World Asia cruise liner, Aurora Botnia ferry and multiple LNG bunkering ships.

- How: Uses advanced combustion control, hardware finetuning, air-fuel ratio optimisation and two-stage turbocharging to minimise slip.

- Emissions: Lower NOₓ and CO₂ emissions than previous engine models.

- Methane slip level: As low as 0.9% of fuel use on average, which is significantly below the 3.1% default methane slip value in the FuelEU Maritime regulation. - EnviroPac methane emission reduction feature for Wärtsilä 34DF engines

- Already selected by CMA CGM for several of their ships.

- How: Combines Wärtsilä 34DF engines with enhanced engine optimisation software and selective catalytic reduction (SCR).

- Methane slip level: Around 50% lower than a standard Wärtsilä 34DF engine.

A simple rule of thumb is that the less fuel you burn, the less methane you emit. However, it is unrealistic to target, for example, a 50% reduction in methane slip solely through fuel efficiency improvements because it would require an equivalent 50% decrease in fuel consumption. That’s why the focus should be on engines and technologies that both deliver high fuel efficiency and minimise methane slip per kWh across the vessel’s operating profile. Download this eGuide to learn more.

5. How can methane slip be minimised at low engine loads, especially during port operations and vessel manoeuvring?

Wärtsilä has solutions to help ship owners and operators minimise methane slip at low engine loads.

Methane slip tends to be higher at low engine loads for two reasons:

- combustion is less complete, and

- cylinder temperatures are lower.

This is a common issue for vessels, especially when manoeuvring or during port operations.

Engine-related solutions for minimising methane slip at low engine loads

Wärtsilä dual-fuel marine engines achieve some of the lowest levels of methane slip in the maritime industry. With the addition of Wärtsilä’s NextDF technology – available for most modern Wärtsilä engine platforms – methane slip levels are now on average as low as 0.9% of fuel use across a wide load range, including at lower loads.

For Wärtsilä 34DF engines, the EnviroPac feature reduces methane emissions by around 50% compared to standard 34DF engine models.

Hybrid solution for minimising methane slip at low engine loads

Converting to a Wärtsilä hybrid propulsion system can dramatically reduce methane slip by allowing engines to run at their most efficient load points. During port operations or when manoeuvring, battery energy storage handles 100% of the power demand. This reduces both fuel consumption and methane slip.

Solutions like these are already in use on vessels such as Wasaline’s Aurora Botnia ferry.

6. What retrofit options exist for older LNG-fuelled vessels to reduce methane slip?

Common strategies to reduce methane slip on older LNG-fuelled vessels include combustion system upgrades and/or control software optimisation. A Wärtsilä retrofit can reduce methane slip by up to 65%.

Wärtsilä four-stroke engine upgrades can achieve significant methane slip reductions of up to 65% depending on the engine and operating profile.

The upgrades are available for Wärtsilä 34DF, Wärtsilä 46FDF and Wärtsilä 50DF engines. More modern engines already have methane slip levels below the 3.1% default methane slip value in the FuelEU Maritime regulation.

Spark Gas (SG) conversion for Wärtsilä 50DF engines can achieve a methane slip reduction of up to 75% and fuel savings of up to 4.6%.

7. What are the typical methane slip rates for different marine engine technologies?

Methane slip rates vary depending on engine type and technology generation. Modern low-speed two-stroke engines generally achieve very low methane slip levels. Medium-speed four-stroke engines traditionally have had higher values depending on design and operating conditions.

Compared to the FuelEU Maritime default of 3.1% for uncertified engines, Wärtsilä NextDF technology for four-stroke engines can reduce methane slip to 0.9% of fuel use on a weighted average basis. This is very close to the methane slip levels of many current low-pressure dual-fuel two-stroke engines. It must be remembered that actual figures will vary according to engine load, maintenance practices and vessel operational profiles.

NextDF engines such as the Wärtsilä 25DF, 31DF and 46TS-DF are available in all supported configurations for newbuilds. For existing vessels, Wärtsilä offers various engine upgrade packages to minimise methane slip. If you are interested in retrofitting your vessel’s engine with NextDF technology, contact our experts.

8. What are the most effective short-term and long-term tactics for reducing methane slip?

Wärtsilä has developed several effective short and long-term tactics to reduce methane slip. Methane slip from Wärtsilä dual-fuel engines has been cut by 75% over the past 25 years and is now as low as 0.9% of fuel use on average. Wärtsilä has also developed upgrades and solutions to help reduce methane slip from existing engines.

Short-term tactics for sailing fleet to reduce methane slip include:

- Engine optimisation

- Operational adjustments

- Hybridisation

Long-term tactics to reduce methane slip include:

- Choosing advanced dual-fuel engine platforms such as the Wärtsilä 25DF, Wärtsilä 31DF and Wärtsilä 46TS-DF with NextDF technology, or other proven Wärtsilä dual-fuel engines designed to minimise methane slip

- Hybridisation

These measures not only reduce emissions but also improve fuel efficiency – and the less fuel used, the lower the fuel cost. It is always wise to plan ahead so you are ready to adopt the latest engine technology during a major overhaul. Wärtsilä’s experts can help you prepare a business case.

9. How does reducing methane slip impact vessel operations and financing?

Reducing methane slip can deliver both operational and financial benefits.

Operationally, improved combustion and hybrid systems make vessels more efficient and reduce fuel consumption, while optimised load management can extend engine life and lower maintenance needs.

Financially, lower methane slip offers significant benefits when voyages are subject to the EU Emissions Trading System (EU ETS) and the FuelEU Maritime regulation. Vessels equipped with technology such as Wärtsilä NextDF may also qualify for more favourable financing terms.

Next steps to reduce methane slip

Your next step to reduce methane slip will depend on your vessel. Although reducing methane slip can be complicated, there are many different solutions available. From engine software optimisation and hardware upgrades to Wärtsilä NextDF engine technology, every improvement can bring financial and operational benefits.

Reducing fuel consumption with a hybrid setup can help you achieve significant reductions in methane slip – read more in the Wärtsilä white paper: How to spend less on ship fuel and make amazing savings every sailing.

Modern route-planning systems like Wärtsilä’s Fleet Optimisation Solution (FOS) use real-time weather forecasts to plan the optimal route, helping vessels to sail efficiently while maintaining constant power output. By optimising the route and speed, route planning systems like FOS can lower fuel consumption and associated emissions significantly while still ensuring the vessel arrives safely and on time.

We hope you found answers to your questions about methane slip in this article – from how to measure and report methane slip to how to reduce methane slip in your newbuild or existing vessels.

As you can see, although methane slip is a complicated challenge, there are plenty of solutions already available to help you tackle it – and make big savings in operational and fuel costs.

Related solutions

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.