As a sustainably aware company, Wärtsilä is committed to minimising the environmental impact of its products. This is why it has set itself a target to cut Greenhouse Gas (GHG) emissions from its gas engines by a massive 15% between 2015 and 2020. Twentyfour7. caught up with some of the people behind this ambitious plan to find out more about Wärtsilä’s sustainability efforts.

As the impact of climate change becomes increasingly visible around the world, business leaders from planet-conscious organisations everywhere are looking for ways to reduce the environmental impact of their operations and products.

One of them is Wärtsilä.

“We seek to enable sustainable societies with smart technology. By reducing Greenhouse Gas emissions from our engines, we are taking a key step towards fulfilling that purpose,” says Mikael Wideskog, General Manager of Technology Strategy & Innovation Process at Wärtsilä Marine Power Solutions.

There are two principal types of emissions: local and GHG. While local emissions, such as nitrous oxides (NO2), sulphur oxides (SO2), and particulates reduce air quality and cause health issues locally and thus require a local solution, GHGs like CO2 have no immediate impact on human health. Instead, they cause large-scale issues, including severe weather events, crop failures, and ecosystem changes and, as such, require action on a global scale.

Gas engines are more sustainable

Sebastiaan Bleuanus, General Manager, Research Co-ordination & Funding, says the first step towards reducing all emissions is to switch from diesel to gas.

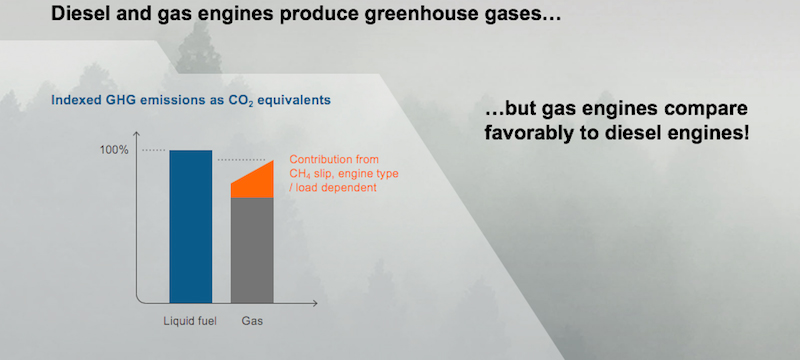

“If you want a pure win-win solution in terms of emission reduction, the first thing to do is choose gas. Not only does a gas engine emit between 13 and 30% fewer GHG emissions than a diesel engine, it also delivers huge reductions in local emissions,” he says. “Gas emits 90% less NO2, 99% less SO2, and 90% fewer particulates. What’s not to like?”

For Wärtsilä, reducing the environmental impact of its products is a continuous project. In 2015, the company set itself an ambitious objective to cut the total greenhouse gas emissions across its entire fleet of gas engines by an average of 15%. At the end of 2017, seven percent had been delivered.

Halfway there

Wärtsilä’s success has been built on its parallel efforts to implement new technologies on existing products, whilst also renewing its product portfolio.

“We’ve achieved close to 50% of our target,” says Bleuanus, “but we still have a lot of work left to do.”

The most significant change arose from the launch of the groundbreaking Wärtsilä 31 engine. When it was introduced in 2015, Guinness World Records verified Wärtsilä 31 as the most fuel-efficient engine in existence.

One of the reasons was that it was the first-ever engine platform to be designed and optimised from the outset to handle three different fuel configurations – diesel, gas, and dual-fuel. Wärtsilä 31 was also developed with cutting-edge fuel economy features, such as increased peak pressure capability, advanced combustion and ignition systems, and enhanced engine flexibility.

Mitigating the methane slip

Wärtsilä is not only working to reduce its CO2 emissions, but also the so-called methane slip, which is the name given to the methane fuel that goes into the engine and comes right out without having been combusted. Methane is an extremely harmful GHG: in fact, it is 28 times more potent than CO2.

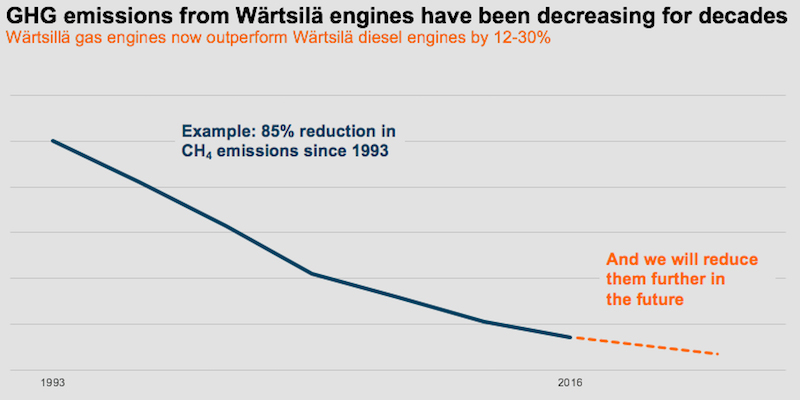

“Knowing the harm that methane can cause, as well as the obvious economic losses associated with pumping in fuel that is not used, Wärtsilä has been working on reducing the methane slip for more than two decades,” says Bleauanus. “Since 1993, we’ve secured an 85% reduction in methane emissions, and we’re not finished yet.”

GHG emissions in Wärtsilä engines.

What next?

During 2017, Wärtsilä identified and determined the technology packages that it will implement on both existing ranges and future products to secure further GHG emission reductions and achieve its 2020 objective. Examples include new developments in battery-engine hybrid technology as well as the potential advantages of connectivity and digitalisation.

“The number of engine adjustments per second made possible by digital technology are huge compared with what we could previously do either manually or mechanically,” Bleuanus notes. “As a result, the digitally controlled engines of the future will be significantly more optimised than their predecessors.”

Headed to a sustainable future

In addition to optimising its own portfolio, Wärtsilä is also working to provide solutions that will help ship owners and power companies reduce their environmental footprint.

“Liquefied natural gas (LNG) as a marine fuel has a crucial part to play in GHG reduction, and Wärtsilä is investing heavily in creating an offer to enable its effective utilisation,” comments Marko Vainikka, Wärtsilä’s Director of Corporate Relations & Sustainability.

According to Vainikka, digital technologies, together with the Smart Marine Ecosystem, will help increase resource efficiency, minimise environmental impact, and increase safety and reliability in marine transport.

“Wärtsilä also welcomes the International Maritime Organization’s strategy to reduce GHG emissions,” he continues. “It’s important to create an industry-wide framework, and this sends a clear signal that we should all join forces in promoting low-carbon shipping.”

Last but not the least, Wärtsilä’s gas engines have a key part to play in the future of clean electricity generation, driven by solar and wind power.

“Wärtsilä’s engine technologies actually enable power systems to rely on renewable energy sources by providing back-up power and adding flexibility to the system, as well as facilitating the use of a variety of fuels, including biofuel. This will ultimately make the power system more efficient, reliable and, also, more sustainable,” Vainikka concludes.

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.