With the continued growth of the wind energy industry leading to an increasing number of wind farms being built, demand for support vessels to build and service them is seeing significant growth. At the same time, owners of offshore supply vessels (OSVs) in the oil and gas industry are seeing a reduction in demand for their assets, with current trends suggesting that utilisation of this fleet will fall to approximately 50% by the end of 2020. In many cases these vessels still have many years of life left in them and similar specifications to those required for wind farm work. This opens up an ideal opportunity to give these vessels new life by converting them.

Giving new life to existing assets

With many countries moving to increase their use of wind power and technological advances in the field making larger and different types of wind farms possible, the wind energy market looks set to offer increasing opportunities for vessels that can support this growth. Cato Esperø, Head of Sales at Wärtsilä Norway, believes that this market will continue to grow: “We’ve seen a huge expansion of wind farms in shallow water and global trends are moving towards further growth. We are also seeing wind farms planned in new areas of the sea, including floating wind farms and larger, higher units that can offer improved efficiency by taking advantage of the better wind resources that are available further from the shore.”

Meanwhile, current trends suggest that after a huge increase in the number of new OSVs in recent years, the utilisation of this fleet has been reduced, leaving many vessels out of use. The rapid development of wind farms means that new vessels will be needed to support their installation and operation on a previously unseen scale. This could create an opportunity for OSV owners to convert their vessels for these purposes. “Some offshore vessels have deck capacity, and they can often be large, stable vessels,” says Esperø. “Many OSVs also have the required power available and their operators can offer long-term offshore experience, both of which are necessary in the wind industry. The fact that we’ve already seen some conversions shows that with the right technical solutions, these existing assets can be given a new life supporting a growing industry.”

Converting under-utilised OSVs for a new future

Esperø highlights that adapting OSVs is not a simple case of converting any available ships. A range of factors, including the current specifications of the vessels and the particular needs of wind farm operators, will determine whether they are suitable on a case-by-case basis: “A key element of identifying a vessel to adapt is whether it is a special purpose ship (SPS)-class vessel and what modifications are needed if it isn’t. Other factors to consider are the vessel’s size, age and remaining life. An analysis of the earning potential of the vessel, along with the cost of conversion, must also be carried out – market conditions for shipbuilding are favourable at present, so a new build could be more economical overall than converting an existing vessel.”

According to Esperø, if an OSV is deemed suitable for conversion then in most cases this should be achievable: “As long as the asset has the essential features required for its new life and there is a good conversion plan to adapt the old technology to the new, most technical issues can be resolved and the conversion can be successfully carried out in a good yard. At Wärtsilä, we can support ship owners from the beginning of this process until the vessel is in service, supplying all of the key elements as an integrated solution including propellers, engines, electric automation systems, navigation equipment and positioning equipment.”

Reducing fuel consumption with hybrid propulsion and other solutions

It is also important to consider reducing fuel consumption and emissions when converting OSVs, because in addition to ever-tightening regulatory requirements for sustainable ship operation, there is also pressure within the industry to maintain a green image for vessels that are used to support the production of renewable energy. As Esperø points out, one way to achieve this is to install hybrid propulsion: “If you look at the upgrades we’ve done, we see a lot of operational savings by installing a hybrid solution, which can help to maximise engine performance and reduce fuel consumption, leading to a reduction in emissions of 10-30% depending on the vessel.” Switching to a hybrid solution can also reduce the operating and maintenance costs of the vessel in the long term.

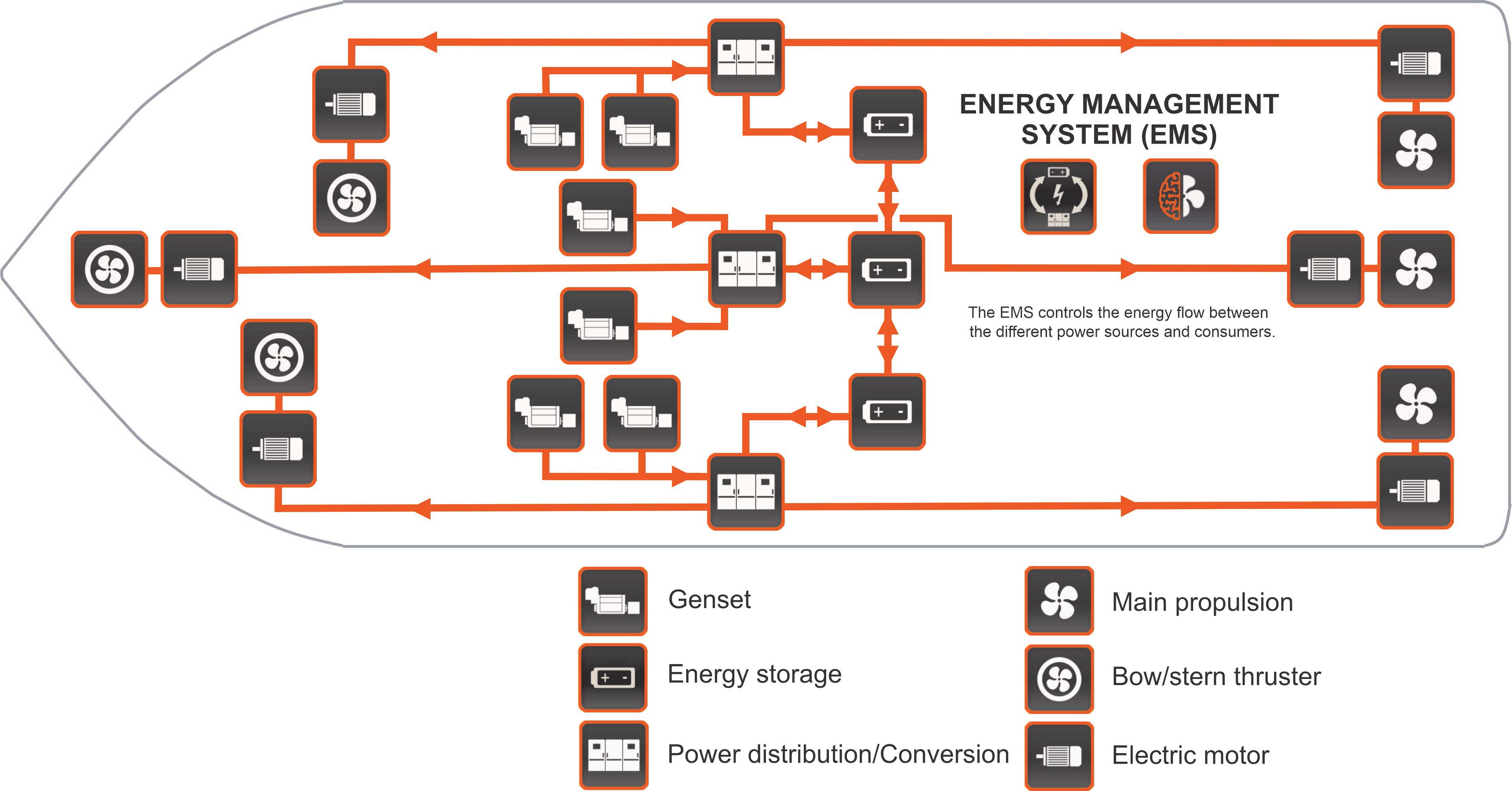

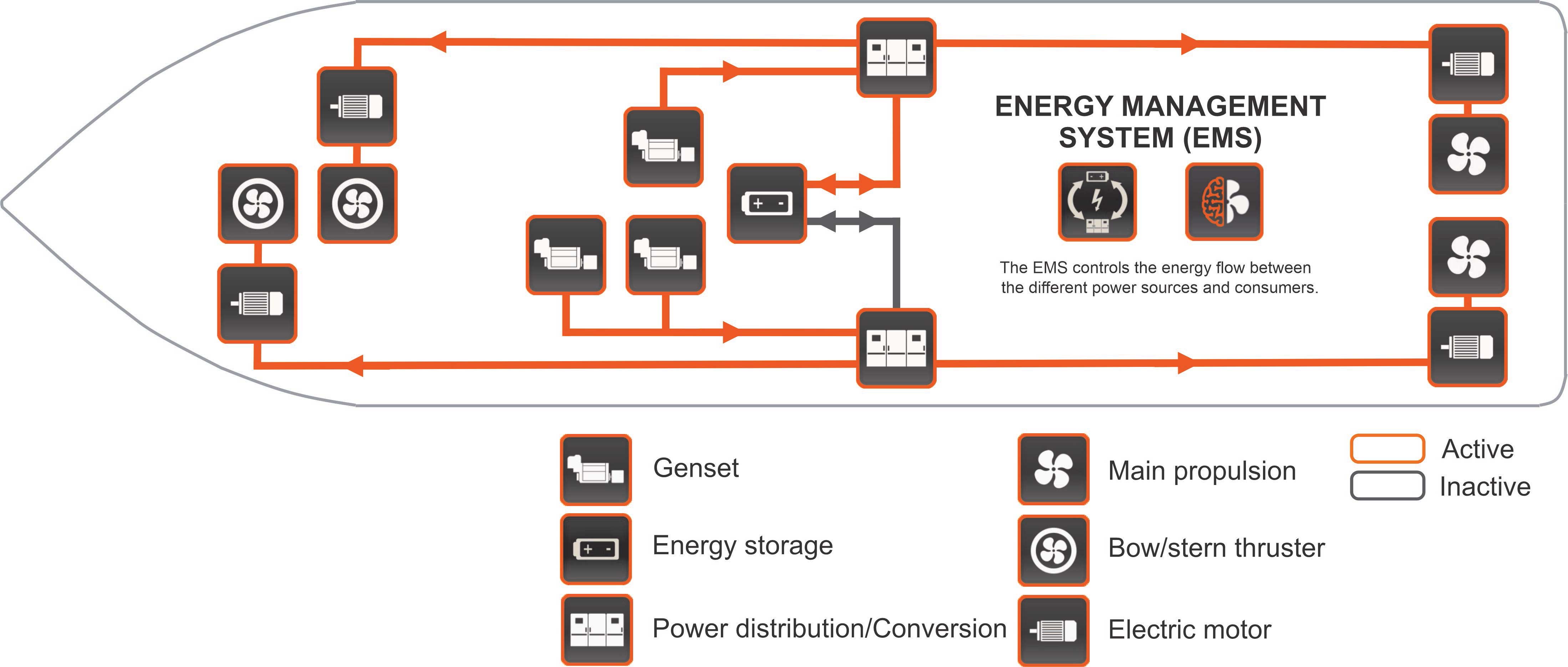

An example of the benefits of hybrid technology can be found in upgrades carried out by Wärtsilä on two OSVs. The Viking Princess and North Sea Giant both had Wärtsilä Hybrid Upgrade solutions installed to optimise the vessels’ overall operation. At the solution’s heart is the Wärtsilä Energy Management System (EMS), which controls and optimises the energy flows between the different power sources and demands in order to deliver efficient propulsion. By increasing the power redundancy, the system allows the engine to operate closer to its optimum design point where it has highest efficiency and least emissions – reducing operating costs and increasing safety while meeting the most stringent environmental regulations.

With the continued growth of the wind energy industry leading to an increasing number of wind farms being built, demand for support vessels to build and service them is seeing significant growth. At the same time, owners of offshore supply vessels (OSVs) in the oil and gas industry are seeing a reduction in demand for their assets, with current trends suggesting that utilisation of this fleet will fall to approximately 50% by the end of 2020. In many cases these vessels still have many years of life left in them and similar specifications to those required for wind farm work. This opens up an ideal opportunity to give these vessels new life by converting them.

Giving new life to existing assets

With many countries moving to increase their use of wind power and technological advances in the field making larger and different types of wind farms possible, the wind energy market looks set to offer increasing opportunities for vessels that can support this growth. Cato Esperø, Head of Sales at Wärtsilä Norway, believes that this market will continue to grow: “We’ve seen a huge expansion of wind farms in shallow water and global trends are moving towards further growth. We are also seeing wind farms planned in new areas of the sea, including floating wind farms and larger, higher units that can offer improved efficiency by taking advantage of the better wind resources that are available further from the shore.”

Meanwhile, current trends suggest that after a huge increase in the number of new OSVs in recent years, the utilisation of this fleet has been reduced, leaving many vessels out of use. The rapid development of wind farms means that new vessels will be needed to support their installation and operation on a previously unseen scale. This could create an opportunity for OSV owners to convert their vessels for these purposes. “Some offshore vessels have deck capacity, and they can often be large, stable vessels,” says Esperø. “Many OSVs also have the required power available and their operators can offer long-term offshore experience, both of which are necessary in the wind industry. The fact that we’ve already seen some conversions shows that with the right technical solutions, these existing assets can be given a new life supporting a growing industry.”

Converting under-utilised OSVs for a new future

Esperø highlights that adapting OSVs is not a simple case of converting any available ships. A range of factors, including the current specifications of the vessels and the particular needs of wind farm operators, will determine whether they are suitable on a case-by-case basis: “A key element of identifying a vessel to adapt is whether it is a special purpose ship (SPS)-class vessel and what modifications are needed if it isn’t. Other factors to consider are the vessel’s size, age and remaining life. An analysis of the earning potential of the vessel, along with the cost of conversion, must also be carried out – market conditions for shipbuilding are favourable at present, so a new build could be more economical overall than converting an existing vessel.”

According to Esperø, if an OSV is deemed suitable for conversion then in most cases this should be achievable: “As long as the asset has the essential features required for its new life and there is a good conversion plan to adapt the old technology to the new, most technical issues can be resolved and the conversion can be successfully carried out in a good yard. At Wärtsilä, we can support ship owners from the beginning of this process until the vessel is in service, supplying all of the key elements as an integrated solution including propellers, engines, electric automation systems, navigation equipment and positioning equipment.”

Reducing fuel consumption with hybrid propulsion and other solutions

It is also important to consider reducing fuel consumption and emissions when converting OSVs, because in addition to ever-tightening regulatory requirements for sustainable ship operation, there is also pressure within the industry to maintain a green image for vessels that are used to support the production of renewable energy. As Esperø points out, one way to achieve this is to install hybrid propulsion: “If you look at the upgrades we’ve done, we see a lot of operational savings by installing a hybrid solution, which can help to maximise engine performance and reduce fuel consumption, leading to a reduction in emissions of 10-30% depending on the vessel.” Switching to a hybrid solution can also reduce the operating and maintenance costs of the vessel in the long term.

An example of the benefits of hybrid technology can be found in upgrades carried out by Wärtsilä on two OSVs. The Viking Princess and North Sea Giant both had Wärtsilä Hybrid Upgrade solutions installed to optimise the vessels’ overall operation. At the solution’s heart is the Wärtsilä Energy Management System (EMS), which controls and optimises the energy flows between the different power sources and demands in order to deliver efficient propulsion. By increasing the power redundancy, the system allows the engine to operate closer to its optimum design point where it has highest efficiency and least emissions – reducing operating costs and increasing safety while meeting the most stringent environmental regulations.

The North Sea Giant, one of the world’s largest and most advanced subsea construction vessels, was upgraded with three energy storage systems which include energy and load sharing capability from and between different DP zones on a DC distribution. Following the retrofit the vessel is now able to manoeuvre with increased redundancy, operating with just one of its six engines and the battery system in DP operation. The vessel can operate on just battery power if the engine stops. In the case of the Viking Princess, one of the vessel’s four engines was replaced with batteries to provide energy to cover load peaks.

Diagram showing the layout of the power systems on the North Sea Giant

Diagram showing the layout of the power systems on the Viking Princess

The Viking Princess

The North Sea Giant

In addition to hybrid conversions like these, Esperø adds that there are other technical solutions that can reduce emissions and improve efficiency. “With vessel owners increasingly recognising the need to reduce their fuel consumption and emission footprints, dynamic positioning and efficient energy management will prove to be key technologies.”

Prioritising functionality and sustainability to meet future needs

“Going forward, no matter what kind of vessels we’re talking about, it will be important for ship owners to consider fuel flexibility and identify technology that can reduce their onboard energy needs – owners need to be ahead of the regulation if they don’t want to get caught out, as it’s getting stricter all the time. With fuel costs expected to continue increasing, hybrid technology and adapting vessels for future green and transition fuels will yield many benefits,” continues Esperø, who concludes: “As a marine technology company, we focus on looking beyond regulations and towards the best technical solutions from the point of view of the customer, keeping an eye on the business case to invest in new technology while also focusing on emissions and energy profiles – this is our joint responsibility as an industry. Wärtsilä can support ship owners with the process of evaluating their assets, deciding what to do with them and moving towards more energy-efficient and low-emission solutions to help owners and operators take advantage of market opportunities.”

Related solutions

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.