Combustion engine vs. Aeroderivative gas turbine:

Derating due to ambient temperature

The increasing need for flexible power across the world, often in harsh climates, makes power plant performance under varying conditions an important consideration in technology selection. Air is required for efficient combustion, making ambient temperature a key factor affecting performance. Gas turbine performance figures are typically presented at 15°C (59°F) ISO 3977 conditions, whereas reciprocating internal combustion engine figures are presented at 15°C (59°F) ISO 3046 conditions.

It is essential to ensure that the power output and efficiency fulfil requirements at local ambient conditions. To compare performance between the two technologies the same conditions need to be applied. As combustion engines are equipped with a turbocharger to boost both the engine’s intake of air and its power output, they are less sensitive to temperature and humidity. This is why Wärtsilä engine power plants outperform gas turbine power plants in above the ISO conditions at 15°C (59°F) or higher temperatures.

Design conditions vs. local conditions

Depending on the technology and site conditions, a power plant’s actual electrical output, efficiency and fuel consumption can be quite different from its performance at design or ISO conditions. Ambient conditions can vary dramatically according to geographic location and by season. For example, summer temperatures depending on the location can exceed 40°C (104°F), while large seasonal temperature swings of over 38°C (100°F) occur in some locations.

As surging temperatures usually correspond to peak electrical demand, a reduction in power output at high ambient temperatures can be problematic. Gas turbines in particular can experience significant performance derating in hot, humid conditions since they are fixed-volume machines.

Ambient temperature, altitude and humidity all affect the density of air. Hot and humid air is less dense than dry, cooler air, meaning there is less mass of air in the same amount of volume. In gas turbines, power output is dependent on the mass flow through the compressor. As the density of air decreases, more power is required to compress the same mass of air, reducing the output and efficiency of gas turbines. For every 10°C increase above 15°C (59°F) ISO conditions, gas turbines experience an efficiency reduction of 1 per cent and a power output reduction of 5 to 10 per cent, depending on the type of turbine. This has a major negative impact on revenues on warm and hot summer days.

Gas turbine manufacturers use various techniques to cool inlet air and boost turbine output, including evaporative coolers and mechanical chillers. However, inlet air cooling requires additional power consumption and capital expenditure, and the efficiency of the cooling system is highly dependent on the ambient humidity. In addition, inlet spray intercooling solutions consume a significant amount of demineralised water. Combustion engines on the other hand are less sensitive to temperature and humidity, retaining their rated efficiency and power output over a broader range of ambient conditions.

How ambient air affects power output

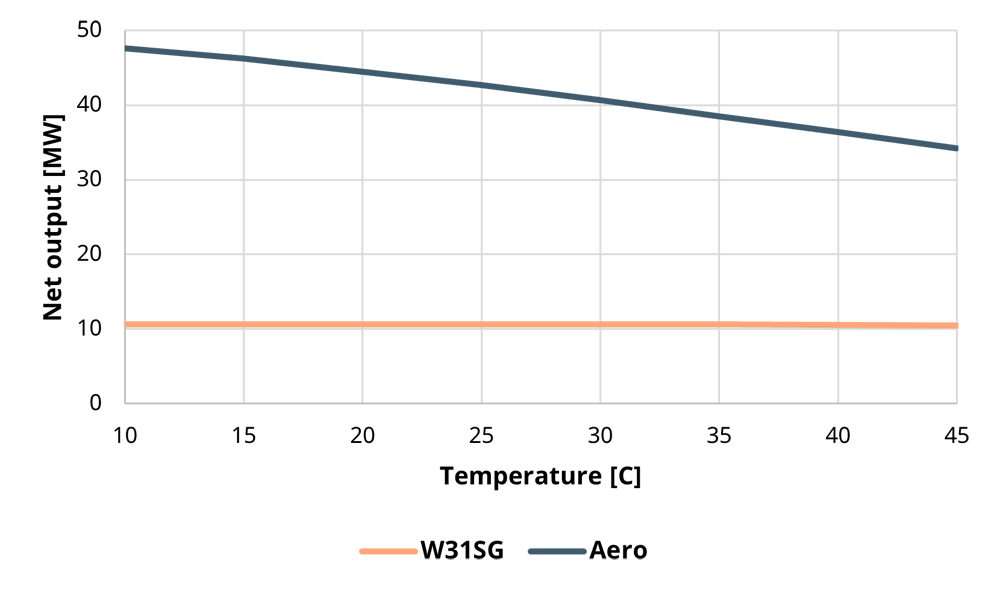

The performance of simple cycle aeroderivative gas turbines and Wärtsilä combustion engines at varying ambient conditions was compared using data from GT PRO®. Figure 8 presents the net power output at varying ambient temperatures ranging from 10°C to 45°C (50°F to 113°F) for an aeroderivative gas turbine and a Wärtsilä engine operating in simple cycle. The turbine’s output decreases by nearly 26 per cent at 45°C compared to ISO reference conditions while the Wärtsilä engine output decreases by less than 2 per cent compared to reference conditions.

Figure 8: Net output derating due to ambient temperature.

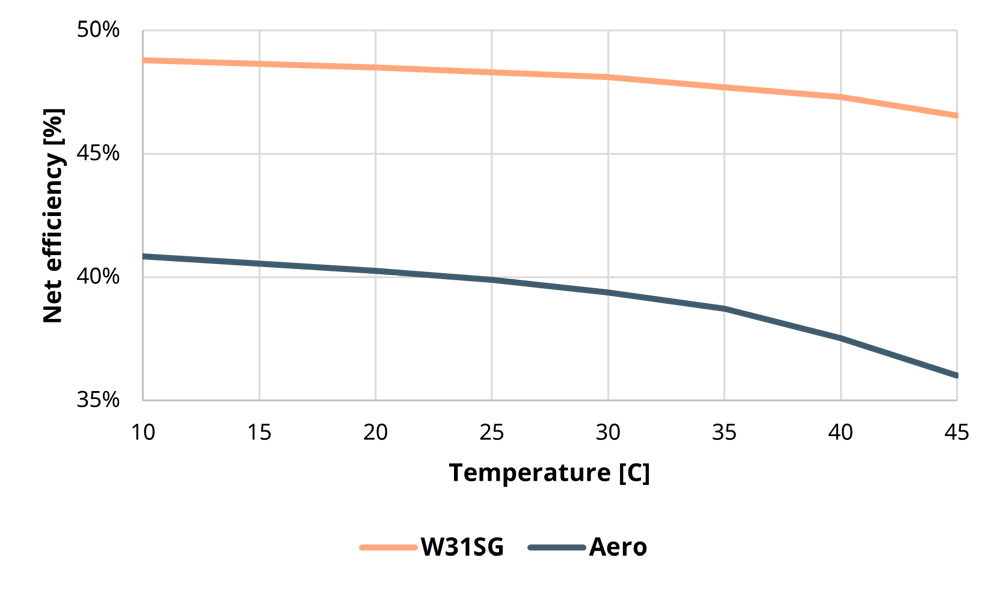

The impact of ambient temperature on efficiency for aeroderivative gas turbines and combustion engines is shown in Figure 9. At an ambient temperature of 45°C (113°F), the gas turbine’s efficiency decreases by over 11 per cent compared to ISO conditions while the Wärtsilä engines efficiency drops by approximately 4 per cent at 45°C (113°F). All values represent net efficiency at the high-voltage grid side at sea-level pressure. While the simple cycle efficiency of aeroderivative gas turbines is approximately 36 per cent at 45°C (113°F), combustion engine can maintain over 45 per cent net efficiency. The impact of ambient temperature on efficiency becomes even more pronounced when the plant is operating at part load. This demonstrates that Wärtsilä engine power plants are capable of offering a wide range of operational flexibility and reliable performance, even in harsh ambient conditions.

Figure 9: Net efficiency derating due to ambient temperature.