Flexible power generation

Engine power plants are the best choice to ensure the stability and reliability of power grids that are using increasing amounts of renewable energy. This is because they can counter the intermittency of renewables and variations in weather in a heartbeat without additional cost. Other power generation technologies don’t have equal capabilities. Engines add the needed flexibility to power grids, securing reliable and affordable energy.

Engine power plants have the added advantage of providing

Excellent dynamic capabilities

Fast and unlimited starts and stops have no additional cost on maintenance.

High efficiency and output in extreme conditions

Excellent performance can be maintained across a wide range of outputs and conditions.

Security of supply

In addition to operating on a variety of gaseous or liquid fuels, engines have low gas pressure requirements.

Sustainable power generation

Emitting fewer greenhouse gas emissions than aeros thanks to higher efficiency with additional value of extremely low water consumption.

Modularity

Brings adaptability, reliability and cost-effectiveness.

Power in a heartbeat - what flexibility truly means

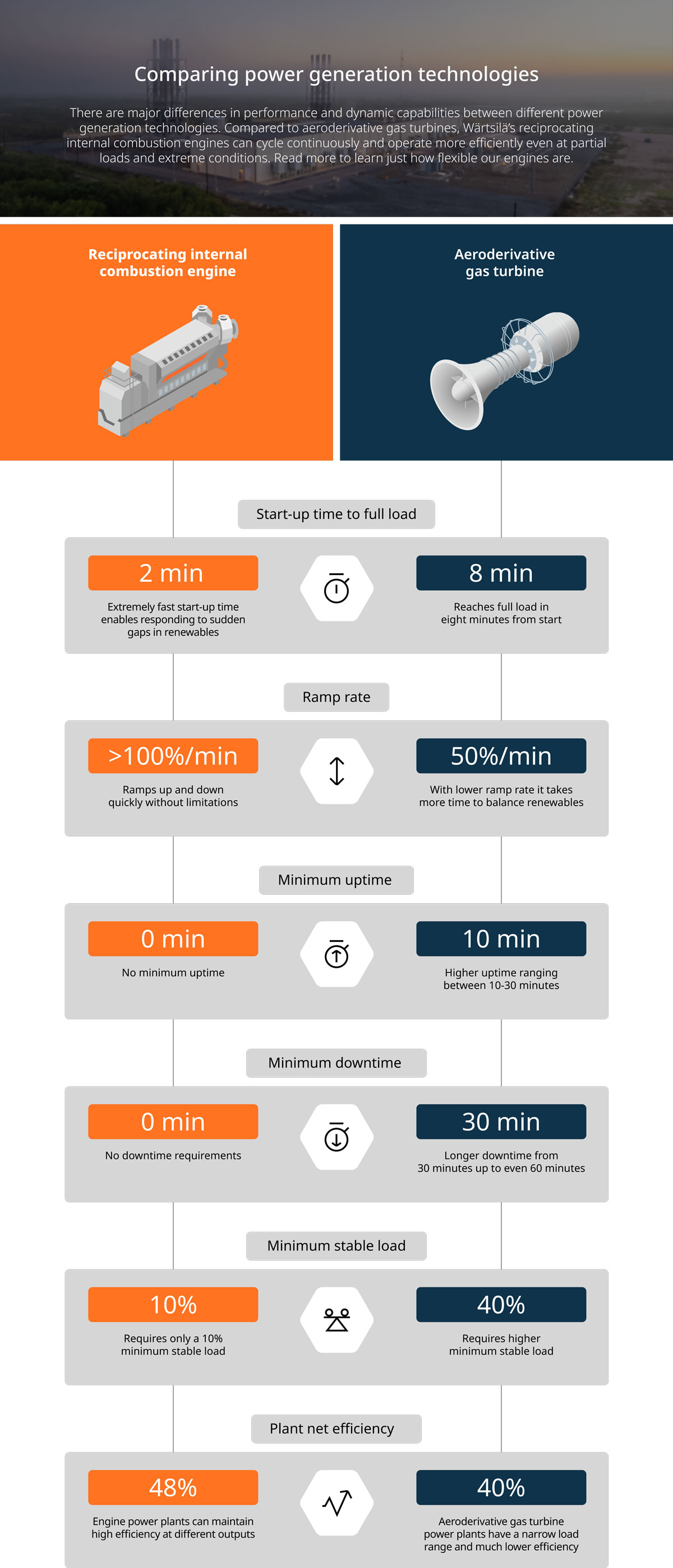

What are the differences between reciprocating internal combustion engines and aeroderivative gas turbines?

Reciprocating internal combustion engines have been proven to start and stop quickly, adjust power rapidly, and operate efficiently at various loads when compared to aeroderivative gas turbines (aeros). To put it another way, engines are more flexible.

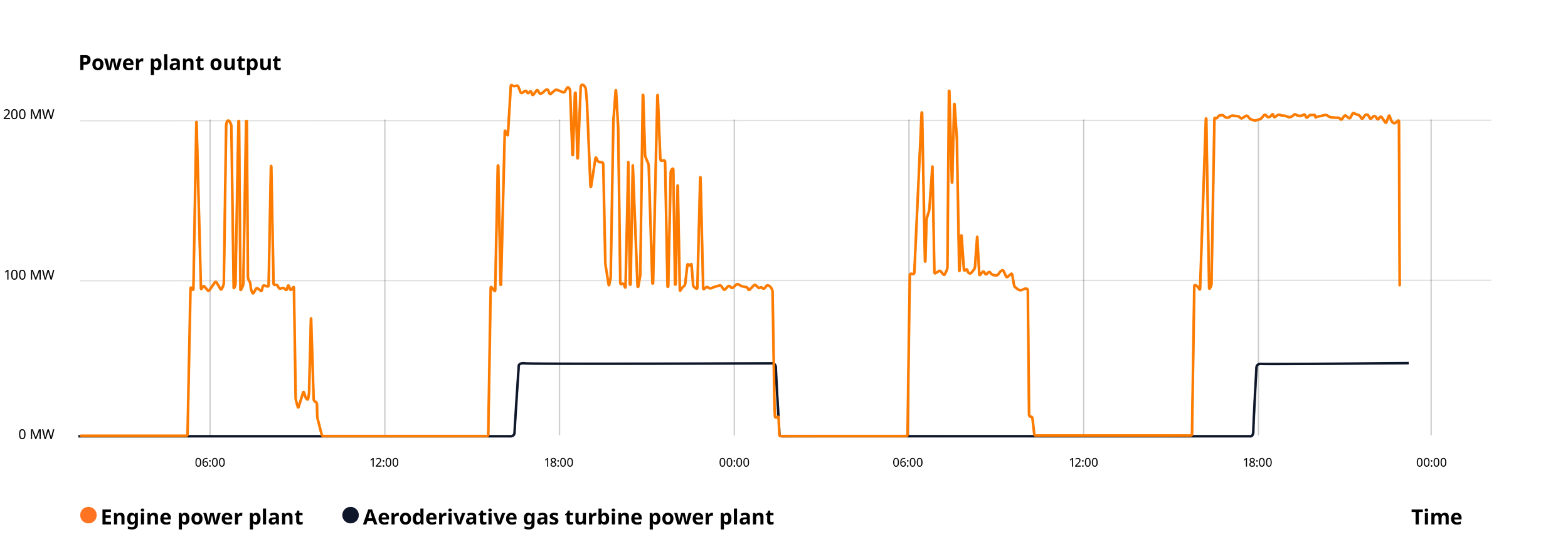

We gathered real-world data from the South Australia’s National Electricity Market to show how two power generation technologies, engines and aeros, behave as a part of the power system.

In the animation video below, we demonstrate the exceptional flexibility that engine power plants provide in balancing renewables. There is now clear evidence that engines are dispatched much more frequently and earlier than aeros. We can also see how the engines provide continuous balancing of renewables on a minute-by-minute basis.

See the flexibility of engine power plants in action

This visual case study, based on real-world data from South Australia's national electricity market, showcases the engine power plant's unmatched flexibility when comparing to an aeroderivative gas turbine power plant in full operation.

Engines are competitive on greenhouse gas (GHG) emissions

Engine power plants emit fewer greenhouse gas emissions than gas turbine power plants. This is partially because they are highly efficient, especially when running plants at 100% load, 25˚C temperature, 30% relative humidity, and consider methane’s global warming potential over 100 years.

Learn more

Related products

Technology comparison article series

These technologies differ in many aspects.

Find out how in the detailed technology comparison articles below.

1. Combustion engine vs. Aeroderivative gas turbine: Introduction

2. Combustion engine vs. Aeroderivative gas turbine: Executive summary

3. Combustion engine vs. Aeroderivative gas turbine: Six elements of dispatching

4. Combustion engine vs. Aeroderivative gas turbine: The advantages of modularity

5. Combustion engine vs. Aeroderivative gas turbine: Part-load efficiency

6. Combustion engine vs. Aeroderivative gas turbine: Pulse load efficiency

7. Combustion engine vs. Aeroderivative gas turbine: Derating due to ambient temperature

8. Combustion engine vs. Aeroderivative gas turbine: Fuel flexibility

9. Combustion engine vs. Aeroderivative gas turbine: Water consumption

10. Combustion engine vs. Aeroderivative gas turbine: Greenhouse gas emissions

Any information including facts, opinions or quotations, may be condensed or summarised and is expressed as of the date of writing and are based on publicly available sources believed to be reliable. The information may change without notice and Wärtsilä is under no obligation to ensure that such updates are brought to your attention.