Ideal power for data centers

As the use of AI and data keeps growing, data centers urgently need reliable, efficient and sustainable power. However, waiting times for grid access can be up to 10 years.

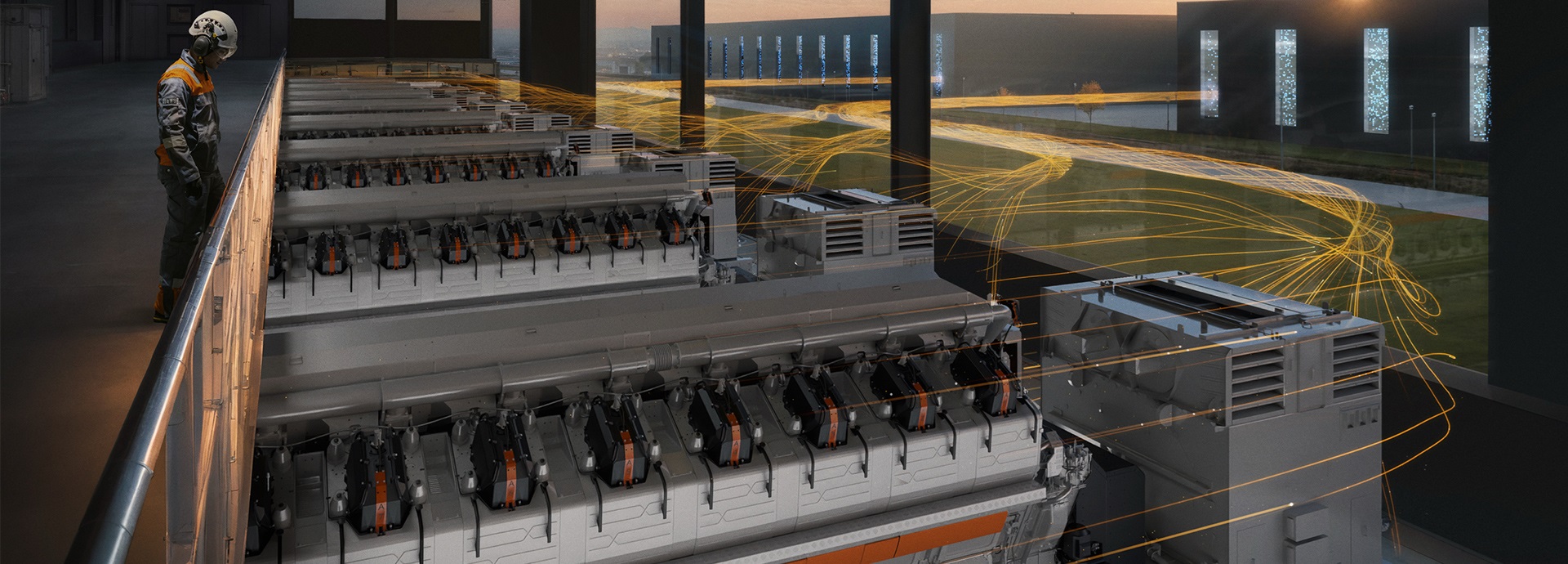

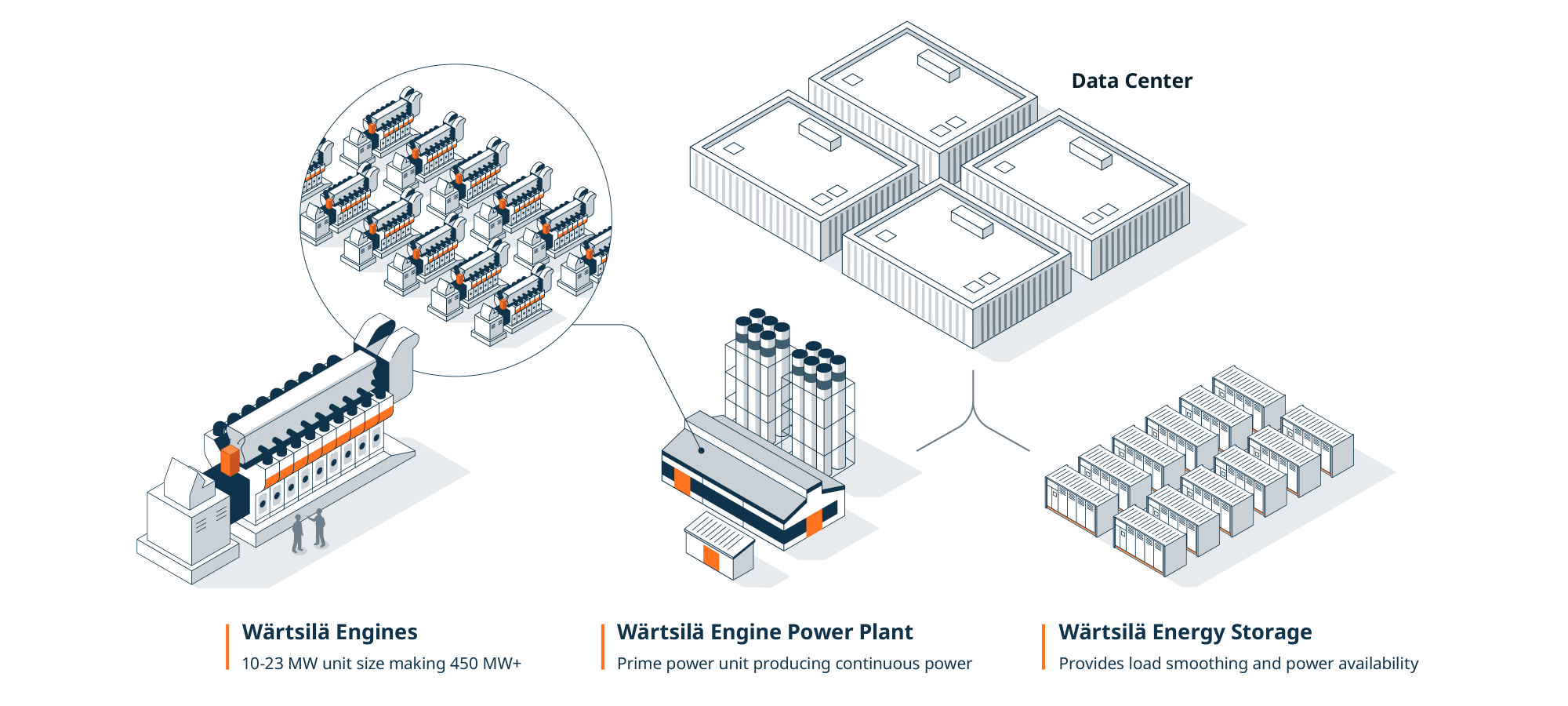

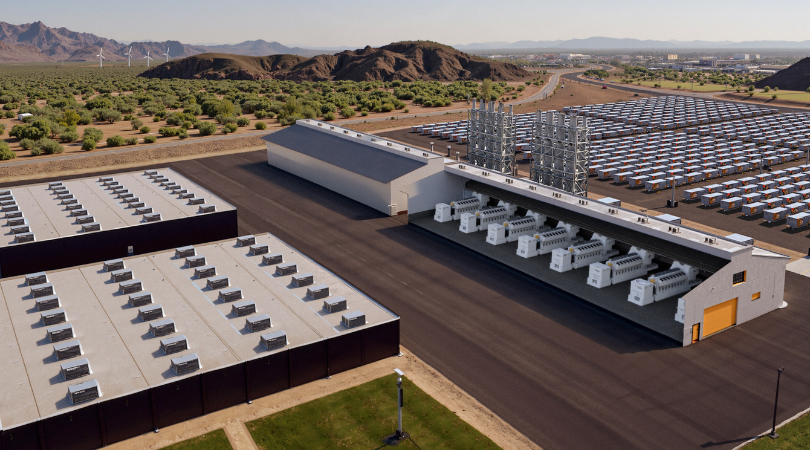

There is a fast way forward: Wärtsilä engine power plants combined with energy storage solutions as an off-grid system that offers reliable and fuel-efficient, sustainable and future-proof primary power.

Key benefits

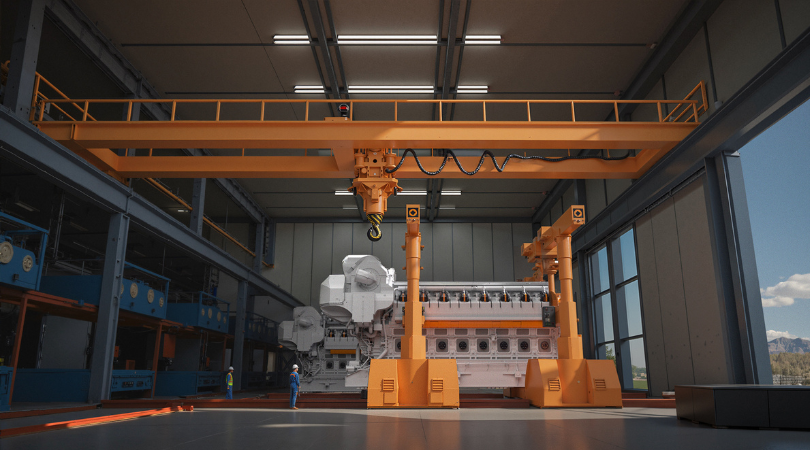

1. Fast delivery and installation

Wärtsilä is one of the most experienced engine manufacturers in the world with a proven record of successful on-time delivery. Efficient logistics enables fast and low-risk delivery. The auxiliary equipment is installed early for a quicker set-up. Large scale plants can be operational in 12 months after manufacturing completion.

2. High temperatures, altitude or water scarcity - no problem

Wärtsilä engine power plants thrive where others struggle. They operate efficiently at high altitudes and temperatures, using very little water. Our engines deliver full power at temperatures ranging from -45°C (-49°F) to 50°C (113°) and the output at over 1,200 meters (4000 feet) is 100%. The water consumption of our closed-loop cooling system with water-to-air radiators keeps process water consumption near zero. Wärtsilä engine power plants consume less than 5 liters (1.3 gallons) of water per hour.

3. High power availability

Not only is Wärtsilä engine technology very reliable, the modularity of the power plant solution maximises availability with redundancy. An engine power plant can deliver uninterrupted power even when one engine is undergoing maintenance. The modular engine configuration also allows rotation between different units, reducing stress on equipment, lowering maintenance costs and extending equipment lifespans. Thanks to their unique ability to handle fast ramp-ups and multiple daily starts, reciprocating engines are like athletes capable of winning both marathons and sprints anywhere. The ability to operate on a variety of gaseous or liquid fuels provides energy security in case of fuel supply disruptions.

4. The most cost-efficient solution for data centers

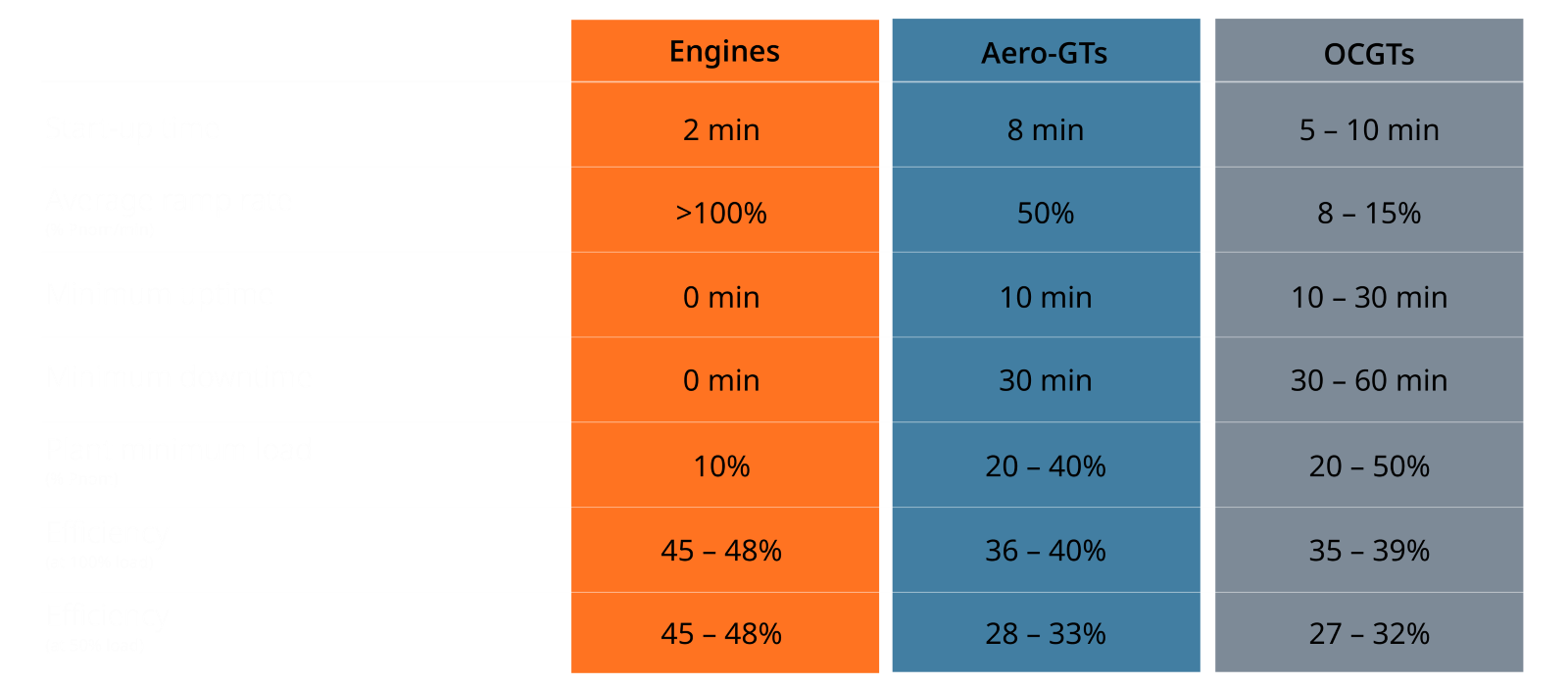

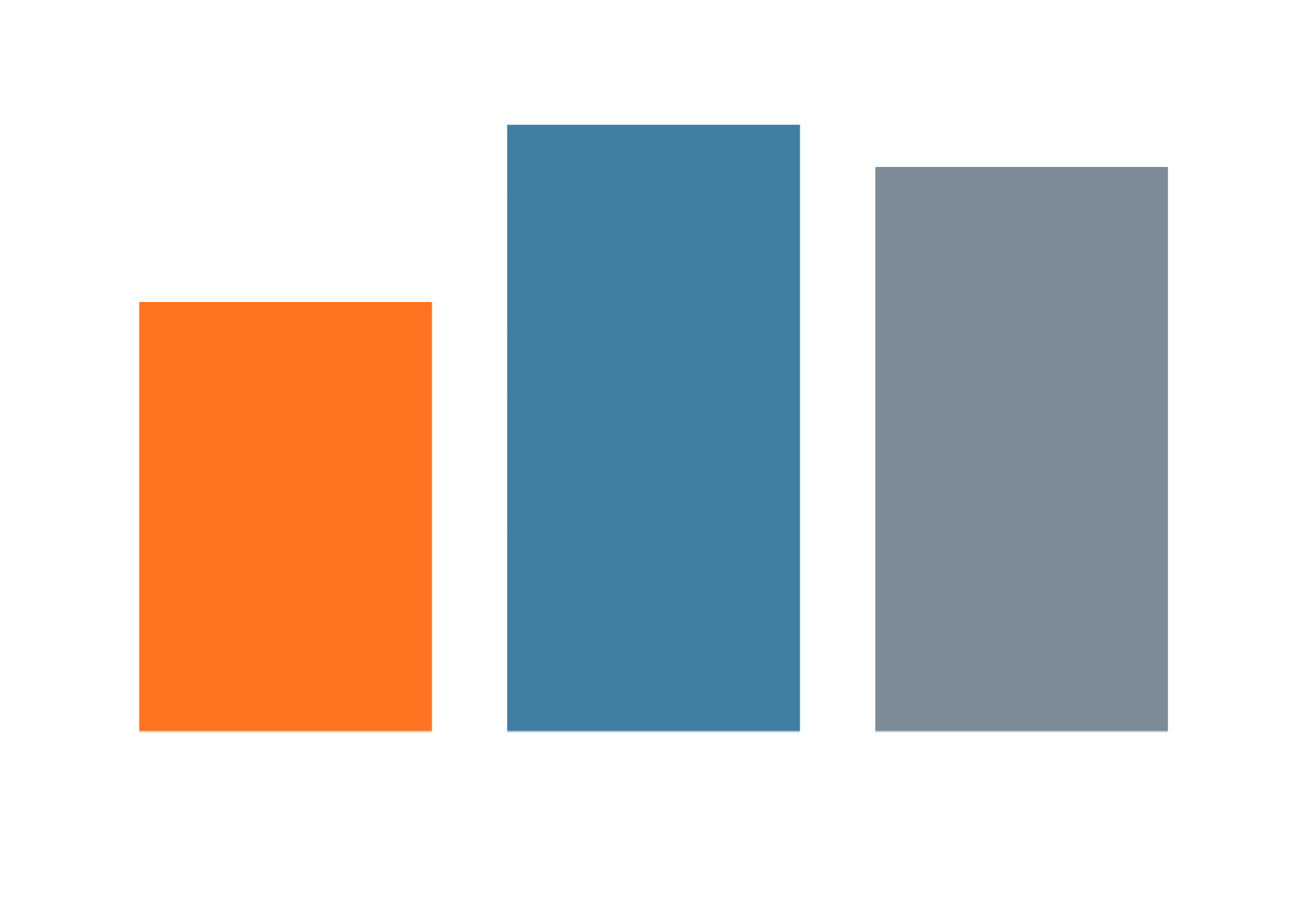

20-30% lower CAPEX

Capital expenses of an engine power plant are 20–30% lower when you include primary power, planned and unplanned maintenance reserve capacity.

Capital cost (US$/kW)

Cost savings through superior fuel efficiency

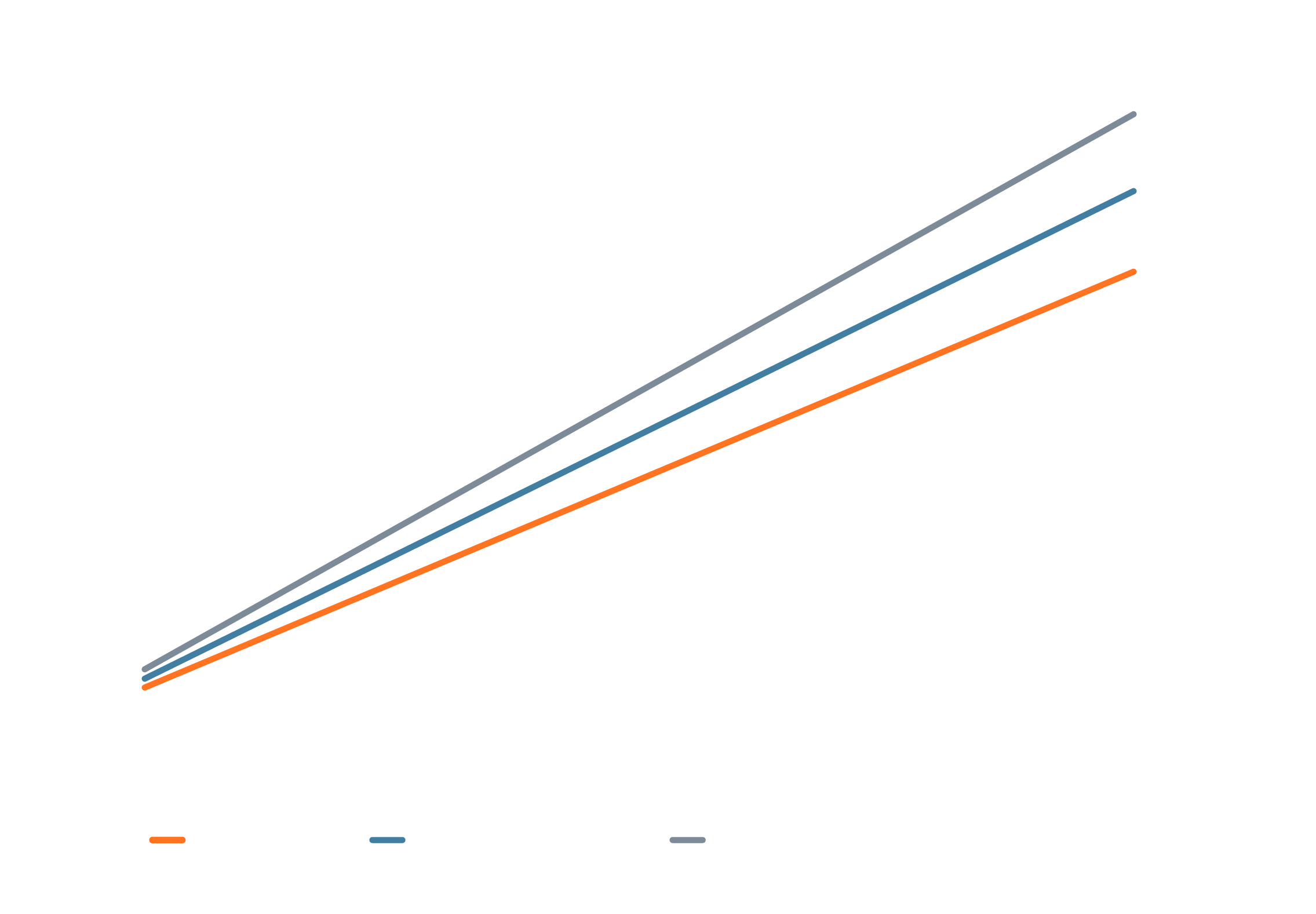

Wärtsilä engines use 20–35% less fuel than gas turbines, and electrical efficiency can exceed 50%. A Wärtsilä engine power plant powering a 250 MW data center can save the asset owner hundreds of millions over a ten year period. We are more than happy to calculate how much you would save.

Cumulative fuel cost/$M - 10 year lifetime

5. Easy, fast and cost-efficient scale up

The modularity of engine power plants makes it easy, fast and cost-efficient to scale up to hundreds of Megawatts without interrupting operations. To meet your growing demand, just add more engine modules.

6. Low emissions ensure compliance

Our self-designed emissions control solutions, combined with the world-class fuel efficiency of our engines, help you reach your sustainability goals effortlessly. Our experts provide emissions data and mitigation technology recommendations. The fuel flexibility of our engines enables you to switch to more sustainable fuels at any point. This helps you navigate regulations, ensure compliance and speed up the permit process.

Explore our power plant products

Turn waste heat into data center cooling

Wärtsilä also offers combined heat and power (CHP) systems that can be used to recover waste heat for data center cooling, further reducing both costs and the carbon footprint of data centers with the plant’s fuel efficiency in some cases exceeding 80%.

Ensuring reliability and efficiency over the whole lifecycle

Is operational safety and predictability your top priority?

Maintenance & Operational support: High-quality maintenance solutions, continuous remote monitoring and support, and AI-powered operational predictability.

Do you also need performance guarantees and on-site support?

Guaranteed performance: Continuous Wärtsilä on-site presence or full responsibility for plant operations – combined with comprehensive maintenance management and performance guarantees aligned to your critical key performance indicators.

Aiming for peak operational performance and efficiency?

Optimisation & Outcomes: Close collaboration and a holistic approach. Optimising individual power plant installations or managing complex microgrids with renewables to reduce emissions and achieve the lowest LCOE. We reach our goals only when you reach yours.

Proven power supplier

of power plant capacity delivered

of operating installed base under service agreements

countries around the world

employees

of our customers agree that we deliver good value for business

Net Promoter Score

Repurpose your off-grid system for balancing and peaking power once the grid connection has been established

Once your data center is successfully connected to the grid, your energy strategy changes. The grid now handles your primary power needs, freeing your engine power plant for new opportunities.

Our engine power plants can then be repurposed to operate as balancing or peaking power sources. This means they can quickly respond to fluctuations in supply and demand supporting intermittent renewables in the grid, making them highly valuable in today's dynamic energy markets.

First step to optimal primary power for data centers: Get in touch

News

Reports

Data centre dispatchable capacity: a major opportunity for Europe's energy transition