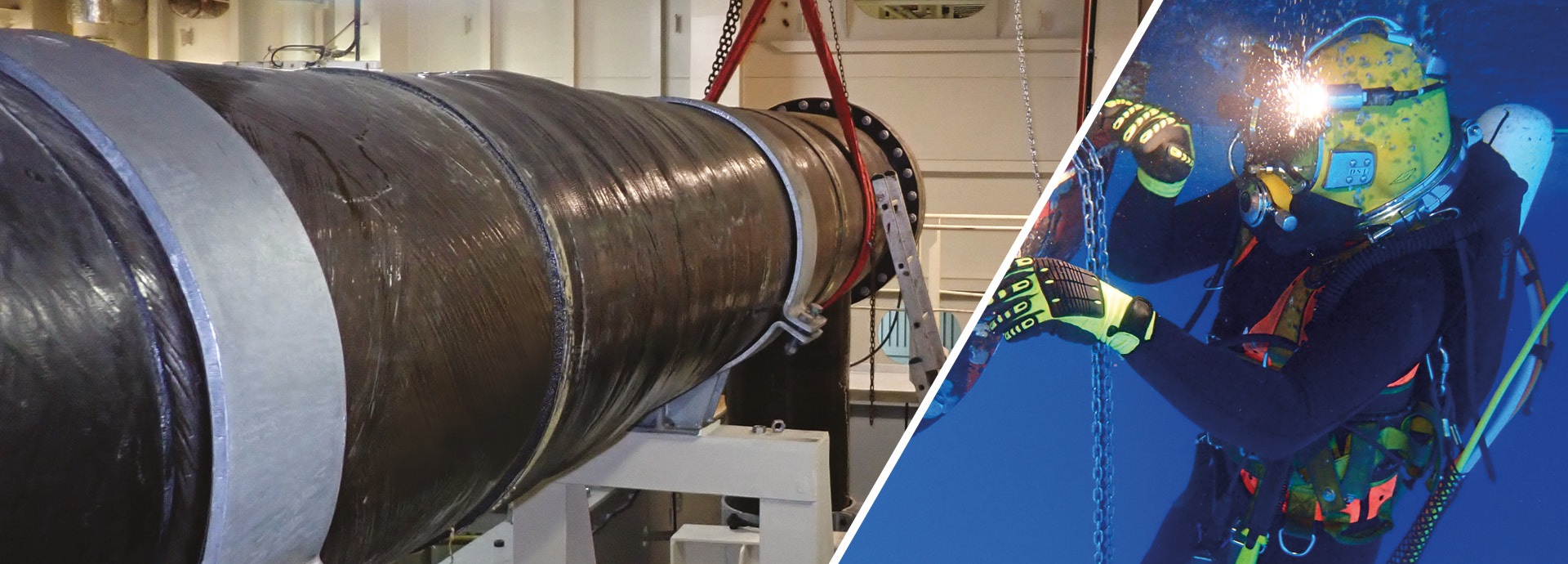

Scrubber overboard repairs with Wärtsilä Underwater Services

Scrubbers are used to remove harmful components from the exhaust gasses generated as a result of the combustion process. Wärtsilä Underwater Services offers a range of innovative Scrubber Overboard Repairs for damage caused by scrubber discharge. Many of these solutions can be carried out in-situ, helping you to avoid costly, unexpected time in drydock.

Our network of factory-trained, industry-certified diver technicians spans the globe, so we’re never too far away. Our high standard of service and equipment means you can count on us to get the job done right.

Patened pipe-in-pipe solution

Developed together with Maersk this solution is exclusive to Wärtsilä. We install an acid-resistant GRE pipe fixed in mild steel pipe that significantly reduces chance of corrosion. This is best suited to large systems and provides a good long-term solution.

Prefabricated stainless steel inserts

A patented solution that is suitable for most scrubbers. This is created with a prefabricated unit that can be fitted using a cofferdams for underwater repairs.

Replacement pipe and coating

With this solution, we weld a new mild steel spool piece into the hull. We also strip off the old coating and apply a new corrosion-resistant coating to protect the hull from acidic water.

Laser-cladded mild steel piping

A new mild steel pipe is installed and protected with a laser cladded cover.

Our skilled diver-engineers use tried and tested solutions to repair damage caused by acidic discharge from your scrubber system.

Downloads

Webinar: Saving downtime costs by repairing overboard scrubber pipework while underway

News

How can we help?

Contact our 24/7 customer support at sls247@wartsila.com for assistance with solutions related to the shaft line.

To enable prompt response, please indicate the Equipment Serial Number or the name of the vessel. Equipment Serial Number is taken from the equipment nameplate and includes all letters and numbers as given on the equipment nameplate.

For all other enquiries, please fill in the online form. Fields indicated with an asterisk (*) are required. We aim to respond within 1-2 business days depending on the scope of your enquiry.