Reconditioning services for ship engine components and spare parts

Economic, high-quality alternative to new engine components such as pistons, cylinder covers, and exhaust valves. Wärtsilä’s reconditioning services can extend the life of your engine components while reducing costs and environmental impact.

Wärtsilä reconditioning services at a glance

- Reconditioning services from Wärtsilä restore marine engine components such as pistons, cylinder covers, and exhaust valves to a better or as-new condition. Reconditioning can save up to 50% of cost compared to new parts.

- You have three options for reconditioning parts and components. You can:

- use the Exchange parts service

- send your own, original part to be reconditioned

- purchase an already reconditioned part without the need to return your old part (availability of parts varies by workshop) - We serve both two-stroke and four-stroke engine parts for the major marine brands , with flexible options for exchange or reconditioning of your own components.

- Backed by 40+ years of reconditioning expertise. The global network and full traceability make Wärtsilä a trusted partner for sustainable, high-quality engine component refurbishment.

What is reconditioning?

Reconditioning is a sustainable way to extend the life of your ship’s engine components. Many components can be restored to a better or as-new condition. This process delivers the same dimensions, specifications, and performance you expect from new parts, but at a much lower cost.

For ship owners and operators, reconditioning can mean up to 50% savings compared to purchasing new components. It gives a longer life for your critical engine parts and reduces waste, which can support your sustainability goals. Because reconditioned components come with a warranty, you can rely on their performance.

Do you want to learn more about reconditioned parts? Good news: here are the top 17 questions people ask about reconditioned parts with helpful answers.

What can be reconditioned?

Wärtsilä’s marine engine reconditioning covers both two-stroke engine parts and four-stroke engine parts, including:

- Pistons

- Two-stroke cylinder covers

- Exhaust valves and valve seats

- Piston rods

- Piston skirts

- Fuel injection equipment

- Four-stroke connecting rods

- Four-stroke cylinder heads

- White metal bearings

We work with both two-stroke and four-stroke engine parts, and our expertise extends to all major marine brands.

Advanced technologies: QS50K™ and QS200

Wärtsilä offers advanced reconditioning technologies such as QS50K™ surface treatment for piston heads and QS200 coating technology for exhaust valves. They both deliver durability, performance, and compliance with the latest environmental standards.

QS50K™ surface treatment for piston heads

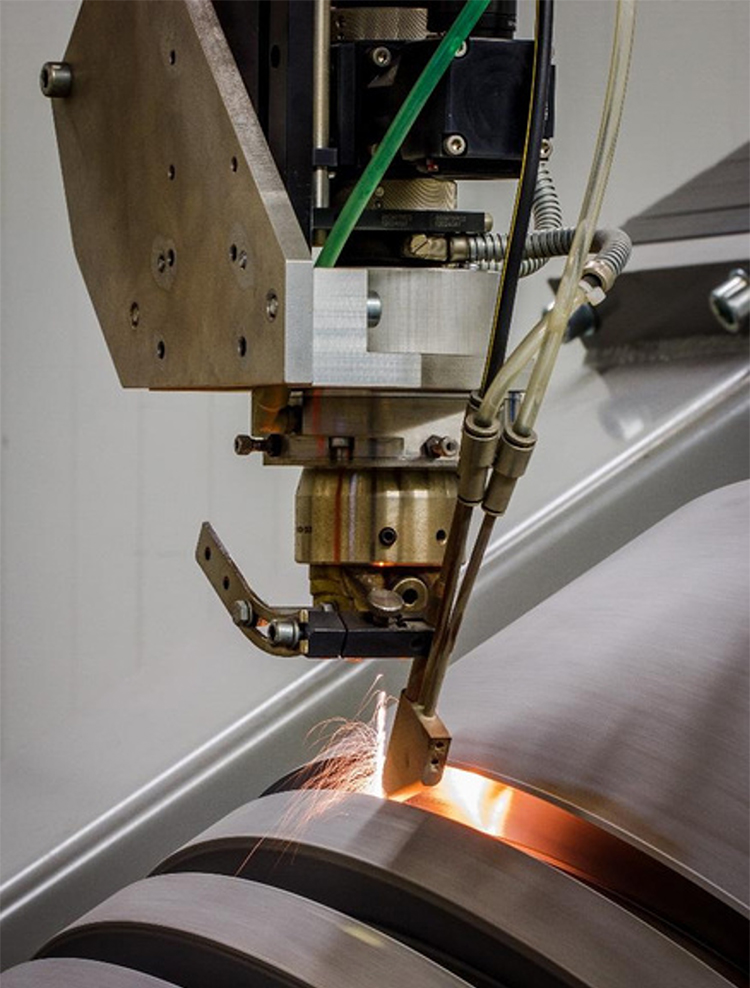

Wärtsilä’s QS50K™ is groundbreaking technology for piston head reconditioning for two-stroke engines. This fully automated, robotic process replaces traditional hard chroming and makes piston ring grooves much more wear-resistant and durable. The result: a longer component lifetime, less frequent inspections, and significant cost savings.

The process includes laser-cladding, precision machining, and final grinding to exact dimensions. Because there is no chrome plating with QS50K™, it gives an important environmental advantage. After all, chrome is being phased out in the EU.

Field tests have shown that piston heads treated with QS50K™ experience minimal wear, and Wärtsilä offers a two-year warranty on the ring grooves.

This technology is currently available in Europe (Netherlands) and Asia (Singapore and China), and can be applied to all low-speed two-stroke diesel engines, regardless of brand.

QS200 coating technology for exhaust valves

Wärtsilä’s QS200 is an advanced solution for exhaust valve reconditioning, and it uses a robotic welding and coating process. This technology delivers a temperature- and corrosion-resistant coating, which means that the time-between-overhaul (TBO) intervals are longer and the safety margins are better.

The QS200 process can also safely recondition valves with significant burn-off: parts that would otherwise have to be scrapped.

The process uses robotic welding, which minimises heat input and residual stresses. And after welding, the valve disc is no longer machined, which preserves the integrity of the new coating.

QS200-coated valves come with a warranty, and the service is available from Wärtsilä’s reconditioning centers in Kruiningen, Dubai, Singapore, and Suzhou.

How Wärtsilä’s reconditioning service works

Wärtsilä offers two flexible models for reconditioning services, the Exchange parts model and the Customer’s own component model. These have been developed to match the most common operational needs. Both options ensure traceability and compliance especially for IMO-regulated engine parts.

Wärtsilä also offers already reconditioned parts in stock for immediate use.

Exchange parts model

The Exchange parts service model is a fast and convenient option. You will not have to wait for the parts to be reconditioned or repaired. Instead, you will get readily available, reconditioned parts and can keep your operations running smoothly.

The Exchange parts service model helps ensure compliance for IMO-regulated parts.

How it works:

1. Order the exchange part from Wärtsilä.

2. Install the reconditioned component in your engine.

3. Return your used part to Wärtsilä.

Result: You can enjoy maximum flexibility and minimise downtime.

The Exchange parts service model covers a wide range of components for

- Wärtsilä, WinGD and Sulzer branded 2-stroke and 4-stroke engines

- Wärtsilä and non-OEM exhaust treatment systems.

Own parts recondition model

This approach is valuable for compliance with IMO regulations and for tracking the lifecycle of critical parts.

How it works:

1. Send your used part to any Wärtsilä workshop. There, the component receives an individual number which is entered into our database for full traceability.

2. The component will be professionally reconditioned using advanced processes and materials.

3. The workshop will return your fully restored part to you, ready for use.

Result: You will maintain full control and traceability for your engine components. This can be important when they are registered in your vessel’s technical file.

Already reconditioned parts option

Wärtsilä also offers already reconditioned parts in stock for immediate use – without the need for returning your old part. The selection of available parts varies by workshop, depending on part type and local inventory. Please contact your nearest Wärtsilä representative for details.

Why choose Wärtsilä for reconditioning?

Wärtsilä brings together decades of experience in engine component refurbishment and reconditioning. You will benefit from a global network and best-in-class reconditioning services for marine engines and components. With 40+ years of experience, we offer unmatched technical know-how and a proven track record in restoring engine parts to as-new condition.

Wärtsilä can deliver exchange parts to meet the customer needs globally:

- There are four reconditioning centers across Asia and Europe:

- Kruiningen, Netherlands

- Dubai, UAE

- Suzhou, China

- Singapore

- Exchange Parts reconditioning services locations are in Europe, North America, and Asia.

Wärtsilä workshop services provide flexible logistics and fast turnaround times. You can pick up and return parts to any of our locations. Wärtsilä also maintains the largest stock of reconditioned parts in the industry, making it easy to find what you need, when you need it.

We offer full traceability for every component, with individual numbering and database tracking. Fleet-wide reconditioning agreements are available, which can help you manage costs across your entire vessel fleet.

Sustainability and compliance

Reconditioning is a smart solution for engine maintenance. When you restore used components, you reduce waste and extend the life of valuable materials.

Our advanced processes, such as QS50K™, eliminate the need for chrome plating, which is being phased out in the EU because of environmental concerns.

Wärtsilä’s reconditioning services are fully compliant with international regulations, including EU and IMO standards. We can help you meet your sustainability and compliance goals while your engines keep running reliably.

Warranties and certificates

Wärtsilä’s reconditioning services offer a six-month warranty on workmanship and materials. Extended warranties of up to two years are offered for selected solutions such as QS50K™-treated piston heads.

The Exchange Parts service offers a full warranty for reconditioned parts (the same as for new parts) – provided that they are installed and operated correctly according to the instructions.

Class certificates are available on request, and our global network ensures you have access to certified, high-quality reconditioned parts wherever your vessels operate.

Frequently asked questions (FAQ)

Ready to extend the life of your engine components?

Discover how Wärtsilä’s reconditioning services could help you operate more efficiently and meet your sustainability goals. When you want to know how our expertise and flexible service models can support your fleet, our team is ready to assist you.