Wärtsilä Operim

The smarter way to continuously improve performance and profitability

Wärtsilä’s Operim– Operational Performance Improvement & Monitoring – provides owners and operators with real-time data on Wärtsilä products and solutions on-board. This enables the implementation of cost-saving operating performance improvements in a continuous and dynamic fashion.

Vessels are only as efficient as the way they are operated and inefficiencies can translate into avoidable costs that impair profitability. Operimutilises the latest digital technology to provide the data needed to allow the vessel, and the machinery driving it, to be operated at optimal efficiency at all times. It monitors performance constantly so that adjustments can be made as operating conditions, including external factors such as sea and weather, change.

Avoid making operating decisions based on assumptions

Precise, accurate data as delivered by Operimmeans that operating decisions no longer need to be made based only on assumptions. By knowing all the facts relating to the vessel’s performance, the guesswork is taken out of the decision-making process and optimal efficiency can be achieved.

Some of the benefits Operim offers:

offers:

- Visibility to analyse every situation

- Knowing and measuring the actual performance of the vessel, its equipment and its systems

- Data collection to create virtual instrumentation and analytics

- Enabling manual or autonomous decision-making in real time, in a predictive or adaptive manner

What next?

Operim is a central pillar in our Smart Marine Ecosystem approach to creating the greater levels of efficiency, safety, and environmental sustainability needed as the maritime industry adjusts itself to meeting the challenges of an emerging new era.

Operim is currently available for Wärtsilä’s gas portfolio, including LNG and LPG Carriers, and will soon be rolled out for Biogas and to water and waste treatment solutions. The long-term vision is for all Wärtsilä assets to be delivered digitally augmented and integrated with Operim

.

At Wärtsilä, we are dedicated to enhancing the lifecycle performance of our customers’ products and systems with fully integrated smart systems. Operim makes this possible.

Digitally Augmented and integrated with Operim

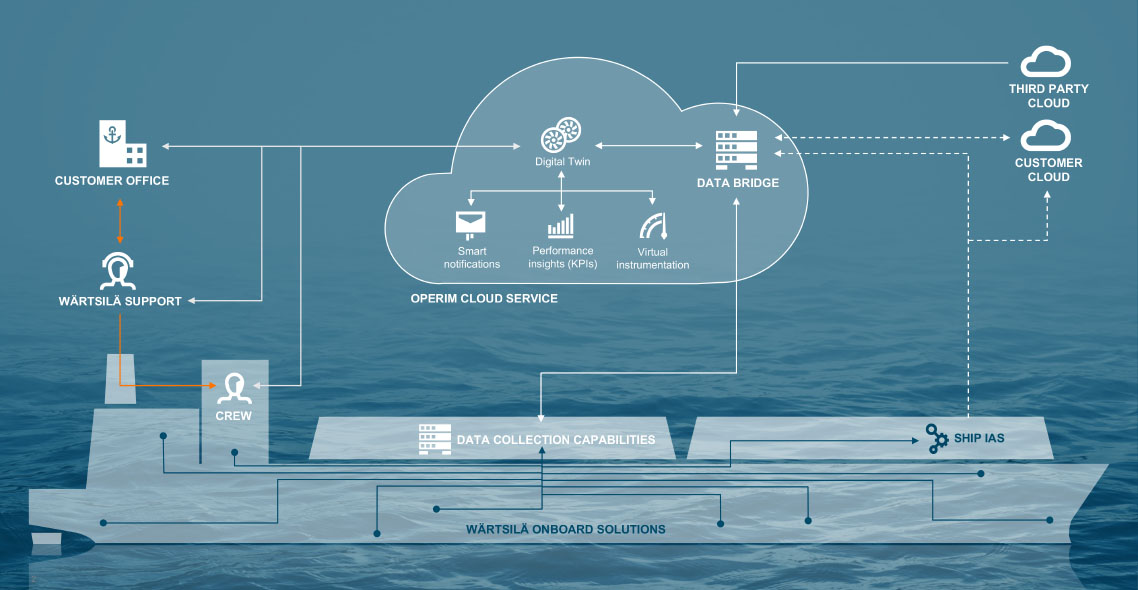

Digitally augmenting the product starts by enabling data collection. This can be achieved in several ways depending on the configuration of the vessel and the customers preferences. Installing dedicated Wärtsilä hardware or using the vessel IAS system. Furthermore, if the customer already has data in a cloud this can also be utilised. Once the data is collected it enters the Operimcloud service the heart of which is our digital twin of the product being monitored.

The digital twin is developed in conjunction with our data scientists and product experts who design the actual product to produce a realistic and insightful digital twin with its roots based in the product. Using the digital twin, we can compare the product actual performance against the calculated and expected performance allowing differences in performance to be identified. These can be then visualised through dashboard in the form of:

- Virtual Instrumentation: Showing either measured value form the product on board the vessel of a value calculated form several sensors e.g. “Super Heat”

- Performance insight (KPIs): Developed together with the product designers and customers.

- Smart notifications: notifications from the system to help improve the operation efficiency

These insights are then accessible to crew on board the vessel and the on-shore team via a cloud-based dashboard, to enable them to use the analytics and insight to monitor and improve the product performance.

OPERIMalso enable Wärtsilä support staff to be connected to provide additional assistance where required. So, in short digitally augmenting the product and integrating it with OPERIM® consists of three key elements:

- Data collection

- Cloud service for analytics and insights

- Customer support

Forget about optimisation – with Operim , it’s always on.

, it’s always on.

Press releases

Wärtsilä agreement will optimise cargo operations for four Knutsen OAS vessels

The technology group Wärtsilä has signed a service agreement with the Norway based fleet operator Knutsen OAS. The contract covers the reliquefaction plant for four LNG Carrier vessels, and is designed to optimise their day-to-day operational performance. The signing took place in March 2022.

The scope of the agreement includes Wärtsilä’s digital Operim (Operational Performance Improvement & Monitoring) system. This provides real-time data on Wärtsilä’s onboard equipment, thus enabling expert management and control to deliver cost-savings and more efficient operations. Wärtsilä will also provide expert technical support, as well as servicing and spare parts support.

“The digital and technical support provided by Wärtsilä are expected to be extremely valuable to us. Having the cargo plant operating at optimal performance at all times will both increase efficiency and reduce our maintenance costs,” says Bjørn Hagland Hansen, Fleet Manager LNG, Knutsen OAS Shipping AS.

“We are able to monitor the equipment in real-time, and have a daily dialogue with the ships’ crews to ensure the best possible performance and deliver any necessary troubleshooting advice. We have enjoyed a long-standing relationship with Knutsen, and this agreement strengthens our collaboration even further,” says Sharique Sayed, Business Development Manager, Services, Wärtsilä Gas Solutions

Wärtsilä will also provide advice on maintenance of the reliquefaction plant and supply spare parts during dry-docking of the vessels. The agreement will enter into effect from June 2022 and is valid for 5 years.

Service agreements are a central element within Wärtsilä’s lifecycle support approach to serving its customers with solutions that enhance their competitiveness and business performance.

Wärtsilä Gas Solutions is a market leader with innovative systems and lifecycle solutions for the gas value chain. Our main focus areas are handling of gas in seaborne transport (storage, fuel, transfer and BOG management), gas to power, liquefaction and biogas solutions. We help our customers on the journey towards a sustainable future through focus on lifecycle, innovation and digitalization.

Media contact for more information on this release:

Mrs Elin Saure Hasund

Sales & Marketing Coordinator, Gas Solutions

Wärtsilä Marine Systems

Tel: +47 81548500

Elin.saurehasund@wartsila.com

Image caption: Knutsen OAS LNGC ©Knutsen OAS

All Wärtsilä releases are available at https://www.wartsila.com/media/news-releases and at http://news.cision.com/wartsila-corporation where also the images can be downloaded.

Wärtsilä Marine Systems in brief:

Wärtsilä Marine Systems supports customers with high quality products and lifecycle services related to the gas value chain, exhaust treatment, shaft line, underwater repair and electrical integrations. We are committed to providing the latest and most efficient solutions, in line with Wärtsilä’s vision for a safe and sustainable future for our customers, our communities and our planet.

www.wartsila.com/marine

Wärtsilä in brief:

Wärtsilä is a global leader in innovative technologies and lifecycle solutions for the marine and energy markets. We emphasise innovation in sustainable technology and services to help our customers continuously improve their environmental and economic performance. Our dedicated and passionate team of 17,000 professionals in more than 200 locations in 68 countries shape the decarbonisation transformation of our industries across the globe. In 2021, Wärtsilä’s net sales totalled EUR 4.8 billion. Wärtsilä is listed on Nasdaq Helsinki.

www.wartsila.com

Get in touch with our team for services, spares and training

Cargo Handling Systems, Fuel Gas Supply Systems, VOC Systems, LNG Systems

Switchboard: 0047 815 48 500 (24/7)

Spares.wgs@wartsila.com

Services.wgs@wartsila.com

Training.wgs@wartsila.com

Inert Gas Systems

Emergency phone: 0047 917 96 874 (24/7)

Biogas

Emergency phone: 0046 480-770040 (24/7)

parts.biogas@wartsila.com

support.biogas@wartsila.com

Services.puregas@wartsila.com