VOC is not waste! Let our recovery system collect and reuse it – for a smaller GHG footprint

Volatile organic compounds (VOC) are light components of crude oil, which evaporate during loading operations or during the carriage of high-volatility crude oil cargoes. Traditionally this cargo vapour has been vented into the atmosphere to prevent the cargo tank pressure to exceed the design pressure. Such venting represents both an enviornmental problem and a great loss of energy. In total, the emissions of VOC from global sea transportation account for a total of more than 5 million tonnes per year.

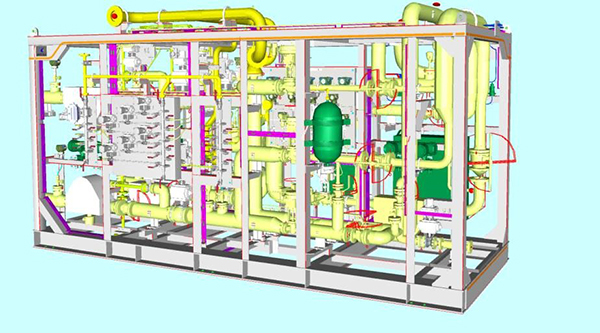

The Wärtsilä VOC recovery system have traditionally been installed in North Sea shuttle tankers. In order to serve more loading crude oil tankers with on VOC recovery plant, Wärtsilä is now offering a system in cooperation with Vaholmen VOC recovery (see web page Vaholmen.no), where the VOC Revovery Unts is installed on a DP2 Plattform Supply vessel.This is conncted to the VLCC Vapour manifold through a hose and all emissions are treated onboard the PSV, now renamed to VOC Recovery Vessel (VRV).

Technical data

LVOC is a potent fuel with an calorific value similar to LPG and LNG. However, the Methane number is low, which means that it cannot be used alone in an Otto type combustion engine due to knocking.

However, in a diesel type engine LVOC can be injected as the only fuel.

Vaporized LVOC can be used in Gas Turbines and Boilers without any Pilot.

Applications

When LVOC has been produced, either on a shuttle tanker or a VOC Recovery Vessel (VRV), there are several options to use the LVOC as fuel:

- Vaporized, as fuel in a boiler

- Vaporized, to produce inert gas

- Vaporized, to run a Gas Turbine

- Vaporized and used as Pilot fuel when burning SVOC in a boiler or Gas Turbines.

- Mixed with LNG and used in a Combustion Engine, using WGS’ proven mixing technology

- Mixed With LPG or as only fuel in a Liquid Gas Engine, utilising WGS LPG Liquid Fuel Supply System (LFSS)

- Vaporized and used in fuel sharing with MDO in a Dual fuel engine

Key benefits

Individual needs and infrastructure will decide how to utilize the LVOC.

VOC consists of all Hydrocabons from methane to octane. Methane is a very potent GHG, while NMVOC is assumed to be around 4 times worse than CO2.

This means that the recovery of VOC is an important environmental action. In addition we are producing fuel which can be used for several purposes. This will reduce the consumption of other fossile fuels onboard and it will reduce the need for bunkering.

LVOC might also be spiked back in crude oil or sold as a feed stock for refineries.

On a VRV there will always be a surplus of LVOC and the two latter options must be considered.

All in all fuel saving and CO2 emission reductions will provide a good payback for the environmental friendly VOC prosjects.

WGS have developed fuel supply systems for all applications:

- LNG / VOC mixing unit

- LFSS

- LVOC Vaporizer unit

Contact our 24/7 customer support at +47 815 48 500. For spare parts, please e-mail us with the equipment serial number or the name of the installation at moss-spares@wartsila.com (Inert Gas Systems) spares.wgs@wartsila.com (all other products)

For technical support & service, please email us with the equipment serial number or the name of the installation at services.wgs@wartsila.com.

Equipment serial number is taken from the equipment nameplate and includes all letters and numbers as given on the equipment nameplate.