Provide solutions for biogas upgrading and liquefaction

Wärtsilä Gas Solutions' energy-efficient mixed refrigerant (MR) liquefaction technology is ideal for liquefaction of upgraded biogas and low-capacity natural gas liquefaction. Our fast-track engineering model, combined with the MR technology, result in low investment costs and short manufacturing time.

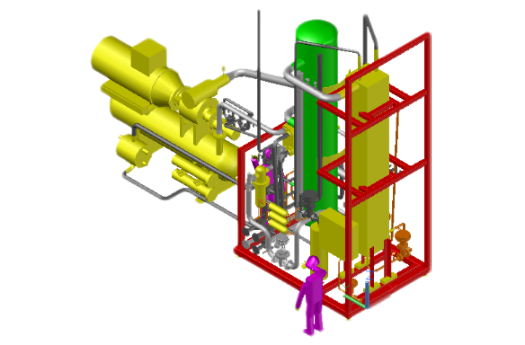

In our MR-based liquefier system, one single compressor and one aluminum plate-fin heat exchanger are the main components. A standard chiller is incorporated to improve energy efficiency and to ensure stable operation of the MR process.

Wärtsilä Gas Solutions' biogas liquefaction plants are based on the Mixed Refrigerant – MR – Process. The MR process is optimized for biogas liquefaction in the range of 10 to 50 tons per day.

Technical data

- Complete plant delivery including storage tank and export filling station to trucks

- Standard capacities: 6, 10, 17, 25 and 50 tons/day

- Low energy (power) consumption: <0.65 kWh/kg LNG

- Produces bioLNG/LBG/LNG at – 160 C

- Designed for unmanned operation

- Plant delivered in factory tested (FAT) and weatherproof modules, no extra housing needed

- Compact footprint: 15 x 15 m2 (excluding bioLNG tank and filling station)

- Built with standard and robust components

- Availability >98%

- Delivery time: 11 months from order to operation

Applications

The plant is ideal for production of bioLNG/LBG to be used as renewable fuel for:

- Heavy vehicles (buses, trucks, ships etc.)

- Power production

- Industrial processes (steel, chemical etc.)

Key benefits

- Well proven with multiple references

- Low power consumption – low OPEX

- Produce bioLNG of industrial quality at -160 C that can share infrastructure with (fossil) LNG

- All components are conventional and of robust technology – reducing CAPEX

- Designed for unmanned operation

- Local control of bioLNG export - truck driver can load without assistance from main control room

- Simple energy supply, only electric power source needed

- Easy start up and shut down of all systems

- Short delivery time

- Plug and play philosophy, module based - relocation possible.