Wärtsilä NOx Reducer (NOR)

The Wärtsilä NOx Reducer (NOR) is an emission after-treatment system based on the Selective Catalytic Reduction (SCR) technology for Nitrogen Oxides (NOx) reduction. Since early 1990 Wärtsilä has delivered thousands of SCR and SCR with an Oxidation catalyst (OXI) units.

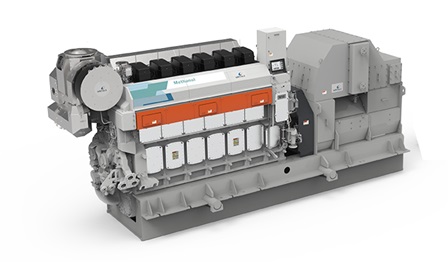

The Wärtsilä NOx Reducer (NOR) is optimized and validated for Wärtsilä medium-speed engines in terms of reliability, easy installation and meeting compliancy over whole lifecycle. It is available for both newbuild and retrofits and is compatible for operation on current and future marine fuels.

Furthermore, with the Wärtsilä NOx Reducer, the overall performance of the engine and exhaust aftertreatment is optimized in terms of emissions reduction, noise abatement, and engine efficiency. Future engine modifications are easier with OEM SCR system.

Wärtsilä provides IMO and EPA Tier III EIAPP certificates for a complete package of an engine and a SCR unit. Beyond IMO Tier III, other ultra-low NOx emission levels are also available. The SCR system can also be integrated with different silencers.

Key benefits

- Secured lifecycle IMO Tier III compliancy with an OEM solution

- Future engine upgrades are much simpler when SCR is considered as an engine component

- High availability of NOx critical components, upgrades, and services - Reliable design validated with Wärtsilä engines

- Straightforward engine + SCR IMO/EPA Tier III certificates

- Easy, optimally scheduled and planned installation onboard minimises risks for delays

- Fuel-flexible: all current and future marine fuels from high Sulphur HFO to ammonia, methanol and other sustainable fuels

- Compatible with SOx scrubbers

- Cost-efficiency with in-built NOx verification tests and the state-of-the-art urea control system

- Cyber secure

Flexibility

The NOR is compatible with the entire portfolio of Wärtsilä 4-stroke engines. The technology has been developed and tested with Wärtsilä engines to ensure safe and flexible operation and it features an integrated communication system. The product also works very well in combination with the Wärtsilä compact silencer and any of Wärtsilä’s scrubbing systems. Together, this forms a complete package comprising efficient energy production, silencing, and a full emissions reduction system. In addition to marine newbuild installations, the Wärtsilä NOx Reducer is available for retrofit installations and land-based power plant applications.

Tier III NOx standards

The IMO’s Tier III regulations typically require SCR systems to be used with diesel operated engines. A marine diesel engine or dual fuel engine installed on a ship constructed on or after 1 January 2016, and operating in the North American ECA and the United States Caribbean Sea ECA, must comply with the Tier III NOx standards. Also starting from 1 January 2021 countries bordering Baltic Sea, North Sea and English Channel form a NOx Emission Control Area. You can read more about the IMO rules at www.imo.org.

Local regulations

There are other strong drivers for compliance, such as the US EPA rules for diesel boats and ships (https://www3.epa.gov/otaq/marine.htm), the Norwegian NOx tax, several inland waterway rules, and local discounts in port and fairway fees.

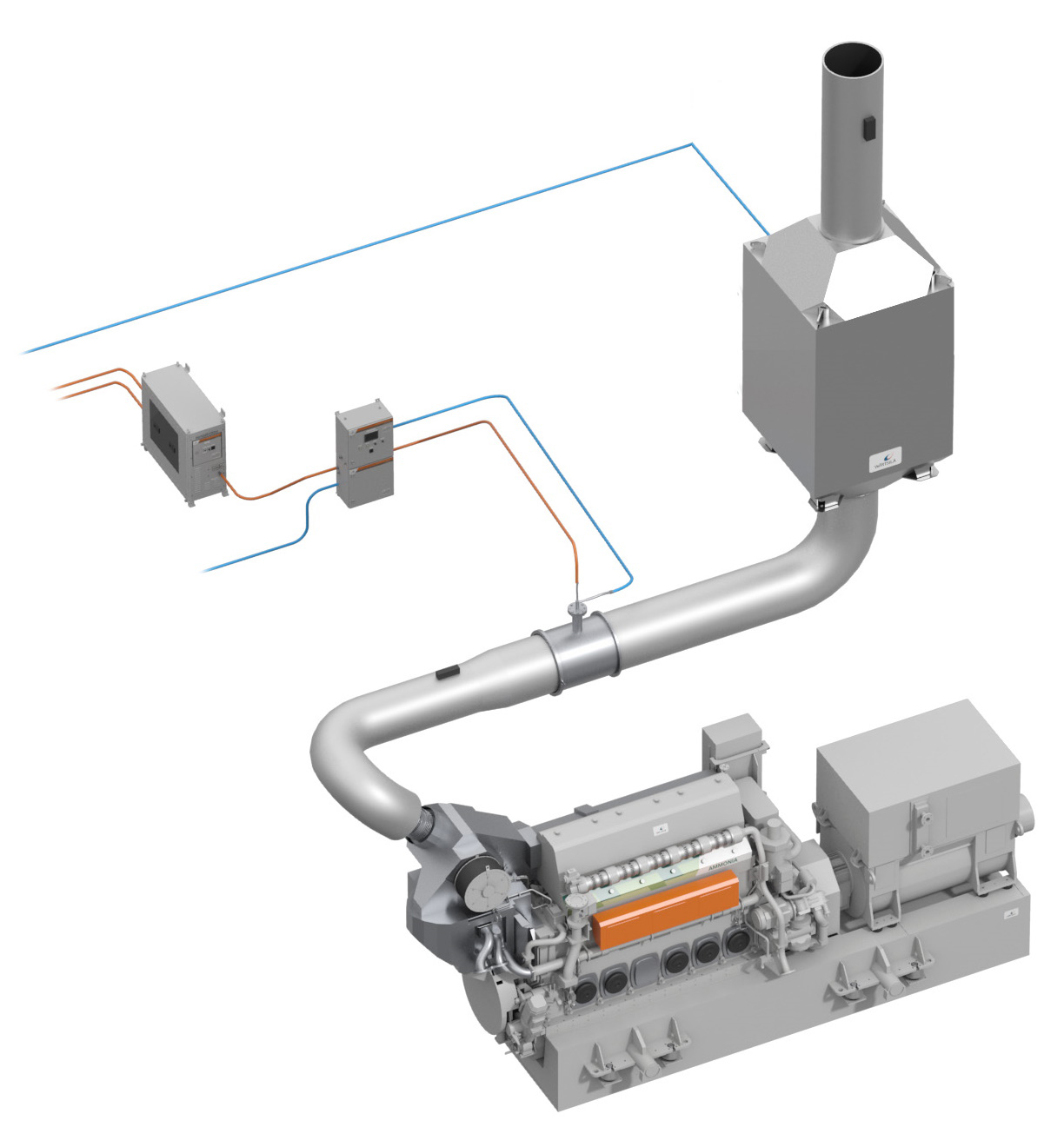

Technical diagram

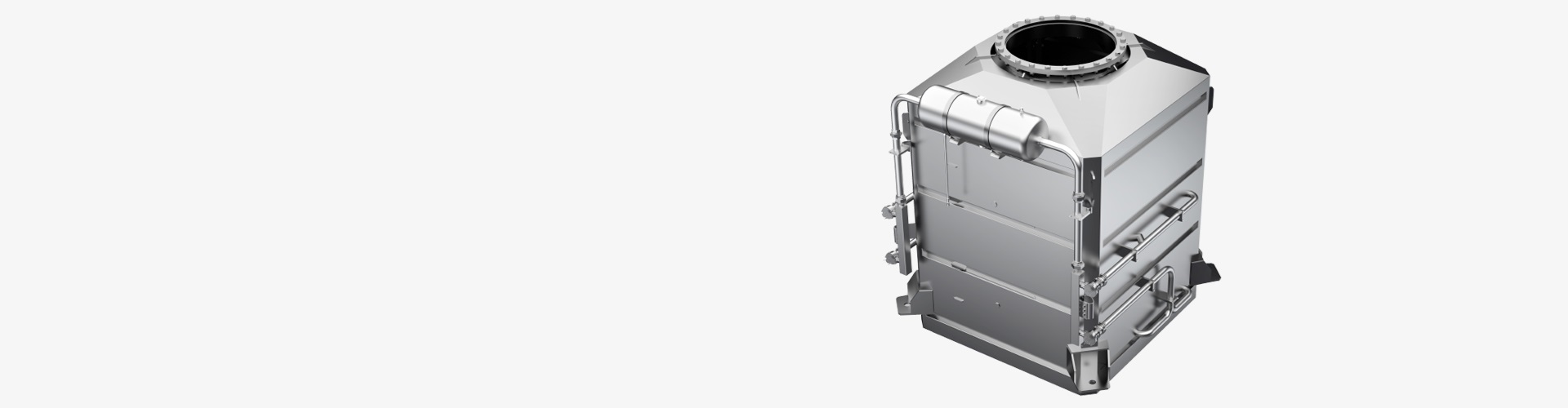

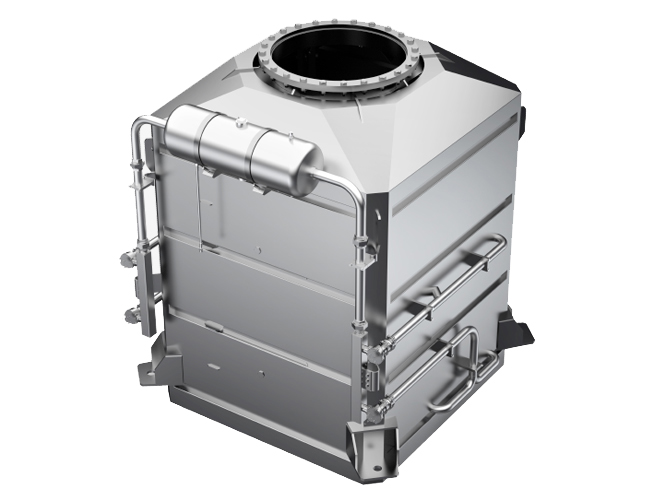

The main component of the NOR installation is the Reactor with a soot blowing unit and the catalyst elements, which are validated with Wärtsilä engines and with different fuel oil qualities. Other essential parts of the NOR system are Urea pump unit, Urea dosing unit, and Urea Mixing and injection unit.

SCR, Selective Catalytic Reduction process

Selective Catalytic Reduction, or SCR, is one of the few technologies capable of reducing Nitrogen Oxides down to the levels required by today’s most stringent regulations.

The Wärtsilä NOx Reducer has been developed to enable vessels to comply with the IMO’s Tier III emission levels, while still maintaining a compact design optimised for marine applications.

The system is safe and easy to use, and fully automatic. It is also available for land-based installations and other NOx levels. In addition to traditional marine fuels, the NOx Reducer is compatible with all new sustainable fuels.