Torbjörn Henriksson has worked with Wärtsilä for six decades. Throughout this time, he has contributed to anything related to ship machineries. Having started his working life in the 1970s, he could have already retired in 2016. But because the exhaust gas cleaning development had just started to significantly contribute to the emission control for the entire marine sector, Torbjörn was too excited to leave the company.

When I was born in 1953, our family lived in a small school where my father was a teacher. In that apartment, we had no toilet or plumbing, so our water was collected from a simple well with a hand pump. When I was four, my parents upscaled their life: we moved to Helsinki and even bought a refrigerator, which many neighbours did not have at the time.

I had my first trip abroad when I was 10 years old—it would be the only one we made as a family. Travelling was less common back then, but it didn’t make growing up any less happy. We made the trip with our family’s new Opel, taking a car ferry to Gotland. It is one of the most memorable moments from my childhood. I recall being on the car deck with my father, enjoying the ship rolling and pitching heavily on the rough sea, while my mother and brother were vomiting over the side. I remember the ship’s heavy movements, and maybe that contributed to my choice to study naval architecture.

In 1969, I bought my first motorcycle, a 2-stroke MZ300 built in East Germany. Although this was a happy moment, it didn’t take me long to replace it with a Yamaha and soon after with a Honda 450. During the 1970s, the Honda took me to most European countries, to the Sahara, around Turkey, and to the coast of the Arctic Sea. All these countries were interesting, and many of the people were just as interested in us as we were in them. These trips made me feel that with good preparation you can achieve anything. It was a reliable bike and one that I still have today – even if I normally drive my Honda 1000.

In 1972, I started studying Naval Architecture at Helsinki University of Technology. This is a decision I have never regretted throughout my career serving the maritime industry. While studying, I was lucky to work as a trainee assembling cranes, as well as spend time on a cargo ship, in a Dutch shipyard, and with the diesel engine manufacturer Gebrüder Sulzer in Switzerland.

Can you start on Monday?

When the traineeship at Sulzer ended, my boss asked me to give Martin “Masa” Saarikangas, a well-known Finnish shipbuilder, his regards upon my return to Finland. When I visited Wärtsilä Helsinki Shipyard and passed on the greeting, Martin unexpectedly asked me, “Can you start on Monday?” They needed a new engineer and Martin wanted me to start working in the Machinery Design Department. This is how my career with Wärtsilä and ship machinery began.

From the very beginning, I was responsible for the main and auxiliary engines and propulsion machinery that were typically delivered by Wärtsilä’s factories in Finland. For seven years, Jarmo Laakso was my inspiring superior and there was a lot of travelling to sub-suppliers; visiting icebreakers in operation sometimes required travelling by helicopter or hydrocopter.

I was still new at the shipyard when I took part in the test of a sewage treatment plant installed on a Soviet icebreaker. Our group was to live on the icebreaker for one week, tasked to use the toilets onboard while others monitored the sewage treatment. That was a fascinating and crucial duty: it was only after the completion of the test that a certificate could be issued and the ship be delivered. In addition, I learnt a lot about the ship and improved my Russian skills.

During my career, I’ve learned many lessons. For example, when the anchors were lifted during my first sea trial with the small cable-laying ship Emba, one of them had caught on a cable at the bottom of the sea. Getting it loose was hard. The ship also suffered a black-out. Nobody understood why, but after an investigation, it was discovered that the Starting Fuel Limiter of the engines had been unexpectedly activated – the malfunction was caused by insufficient signal cable shielding. From this episode, I learnt to be careful with automatic functions.

Wärtsilä was contracted to build the MS Silja Serenade cruise ferry in 1987. The shipowner’s technical leader, Harri Kulovaara, prioritised safety, requiring that the bow dimensioning should be based on the DNV’s rules, as they were safest, although the ship was otherwise built to LR rules. The wisdom of this decision sadly became evident from the MS Estonia catastrophe in 1994.

During the Silja Serenade project, my task was to specify the technical solution that enabled the main engines and propellers to operate even during a black-out. Personally, I felt that it was a smart innovation and a very cost-effective means of improving safety. The Silja Serenade was also the first time I was involved in significant measures for the reduction of exhaust gas emissions.

In 1988, I started to work for the shipping company Neptun Maritime. It was good fun but it didn’t last for too many years. The company’s financial ability to order new ships decreased in late-1992, meaning that those of us in the new building department started to look for new jobs. My years at Neptun Maritime taught me how even the tiniest mistake or malfunction can have a significant impact on the safety onboard a ship.

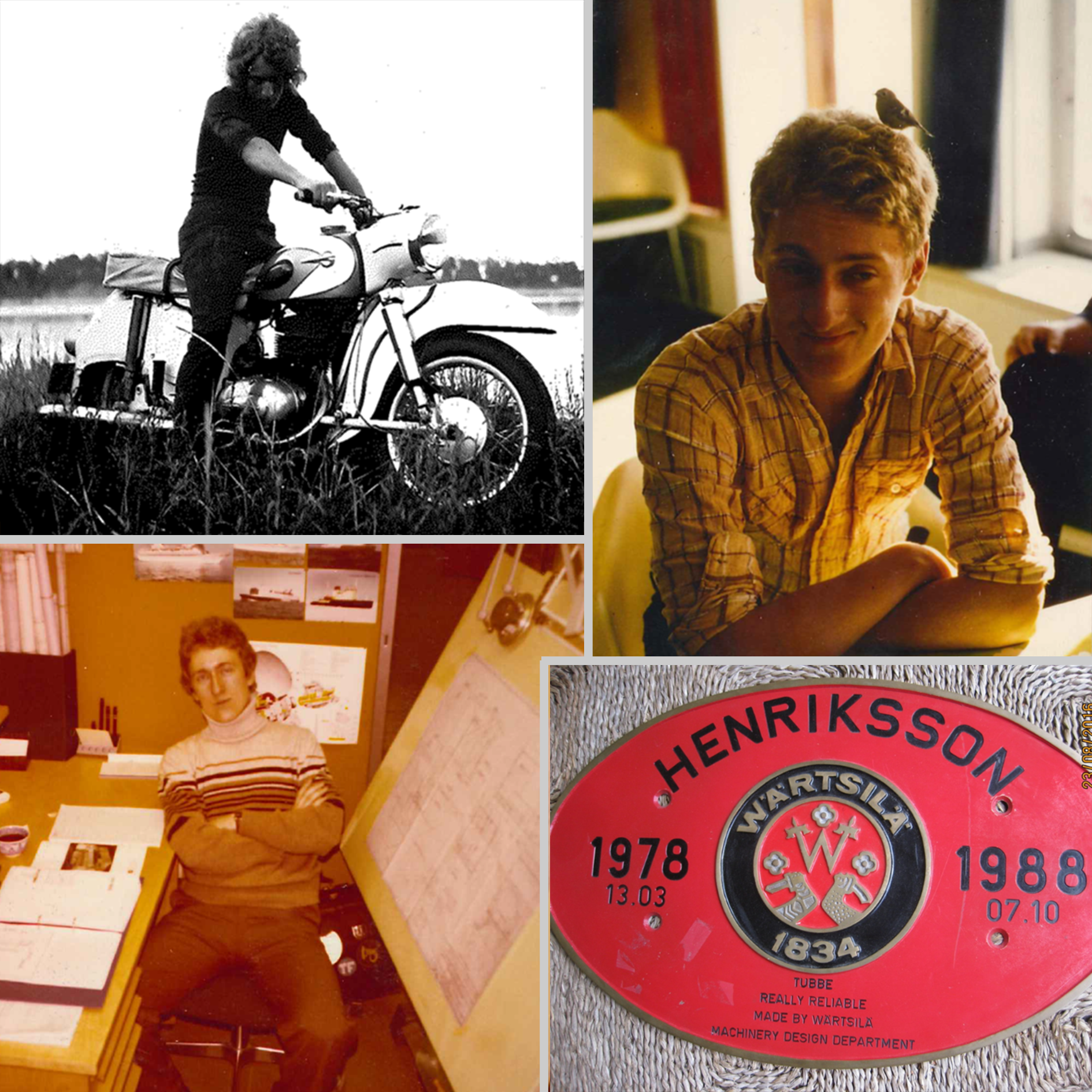

Top row from the left: My first motorcycle, a 2-stroke MZ300 built in East Germany; On board a ferry in the middle of the Baltic Sea, a bird flew into the classroom and perched on my head; My first desk at Wärtsilä; The present from my colleagues when I left the Wärtsilä Helsinki Shipyard 1988, following the design of signs placed on the ship’s bow.

Top row from the left: My first motorcycle, a 2-stroke MZ300 built in East Germany; On board a ferry in the middle of the Baltic Sea, a bird flew into the classroom and perched on my head; My first desk at Wärtsilä; The present from my colleagues when I left the Wärtsilä Helsinki Shipyard 1988, following the design of signs placed on the ship’s bow.

Reconnecting with Wärtsilä

In early-1993, I returned to Wärtsilä in Turku, southwest Finland, where I still work. At that time, the factory was ramping up the production of Wärtsilä 46 engines. For many years, my work was entirely linked to them, including project management, sales support and application technology. However, I did get to participate in other areas, such as the development of the world’s largest 4-stroke engine, the Wärtsilä 64.

My next focus was a result of the tanker MV Braer running aground off Shetland in January 1993, an accident that resulted in the spillage of an immense amount of oil. The root cause was an ingress of seawater in the ship’s fuel day tank after its vent pipe was broken in stormy weather. I personally took the initiative to do a Safety of Life at Sea (SOLAS) amendment to require redundant machinery for tankers and passenger vessels. My initiative was communicated to the IMO and they decided to amend SOLAS to require double fuel service tanks.

This was an improvement but for passenger vessels, the real step forward came much later in the form of the Safe Return to Port requirement in 2010. Only this satisfied my ambition for ship safety; I was clearly on the right track before, but my initiative came too early.

After the Braer incident, I also personally established and managed an international project with DNV, an oil company, a maritime insurance company and a shipyard. The target was to define criteria for voluntary machinery redundancy and encourage DNV to introduce such class notations (RP and RPS), which until then did not exist. As it happens, the report showed that machinery redundancy makes sense financially, which was brought up in discussions with the IMO. Other classification societies soon followed with similar class notations.

As of 2000, our team got to develop LNG Carrier applications based on Wärtsilä 50DF engines. This was really pioneering work and we were very successful in convincing shipping companies to specify dual fuel engines instead of steam turbines in their newbuild ships.

Father of maritime scrubbers

The original MARPOL Annex VI was ratified in May 2004. At that time, the IMO recognised the need for air pollution requirements and there was much attention on sulphur emissions. I started to read about scrubbers and found an article in Marine News declaring that scrubbers are not suitable for ships due to several unsolved problems. Well, that didn’t stop me.

I happened to meet Wärtsilä’s CEO at that time, Ole Johansson, at Stockholm Airport in June 2005 and mentioned that Wärtsilä should investigate scrubbers. He asked me to make a proposal and send it to Tage Blomberg, the group vice president of Service at the time, which I did the next day. He called and asked me to start executing my proposal and that I’d be in charge. I knew nothing about scrubbers, but that’s how Wärtsilä’s scrubber development started.

Immediately after this, I discovered that IMO regulations were not ready for scrubbers. So, I started to work on this and by 2007, I was asked to present scrubbers to an IMO Marine Environment Protection Committee. It became the most significant presentation during my whole working life because scrubbers were not at all known in the maritime industry at that time. Politically, it was not clear whether scrubbers would be an accepted means of compliance with the upcoming more stringent IMO sulphur emission limits.

In 2008, when the IMO then decided to allow scrubbers as an alternative to low-sulphur fuel, I was confident that my contribution had impacted their decision. For the scrubber development, Wärtsilä received some R&D funding that helped move us forward. During 2008, we installed a prototype on a ship and tested and certified it in 2009–becoming the first in the world to receive the IMO scrubber certificate.

As scrubbers were still rather unknown, I travelled extensively, visiting shipowners and shipyards and making presentations at international conferences. When I was presenting to a Finnish shipowner once, he fell asleep. My colleagues were watching me with interest, wondering what I would do next. I decided to continue my presentation, and when I came to my last slide, the director woke up. He never bought a scrubber, but we did sign the first contract with another company in 2010.

During those years, the EU was preparing its so-called Sulphur Directive, which became a highly political issue in Europe, even though the main requirements were very similar to the IMO’s adopted requirements. In 2011, I was invited by the Finnish parliament to explain the use of scrubbers in ships. It was yet another exciting presentation, and I was impressed by how well the Parliamentary meetings were managed.

In 2016, Wärtsilä decided to concentrate all its scrubber activities in Norway–and it was the same year that I reached my retirement age. But with so many interesting things ongoing, I did not wish to retire at 63. Consequently, I was recruited to the Catalyst Systems team, where I continue to have the privilege to participate in the development of IMO Tier III certification of diesel engines with Selective Catalytic Reduction, which aims to reduce NOX emissions.

Not a goodbye

I have had the pleasure of staying healthy and working with environmental technology in a department with a good working spirit. I still feel work is inspiring, offering pleasant social contact, new things to learn and complex challenges to solve in cooperation with colleagues, customers and classification societies. The relationship with my superior, Pekka Kinnari, has also been excellent.

I’ve enjoyed every working day, including those with challenges. I have travelled, met a lot of people and worked alongside many remarkable colleagues. Some of them have become lifelong friends.

From the beginning of 2022, I will start to reduce the hours in my working week. However, it is not yet time to say goodbye to my fellow Wärtsilians, but soon there will be a bit more time for other interests.

My son and two daughters, as well as my four grandchildren, live in Turku, Helsinki and Dublin. All my children have spouses from different countries, so many languages are spoken when we meet. It is good to know languages, so I have started to study Russian purely as a hobby.

Some of the technical and safety-related lessons I’ve learnt during my career

- Be careful with automatic functions.

- Inspect measurement records upon receipt without delay to ensure conformity.

- In case of non-conformity, determine the need for corrective actions, and develop enhanced quality procedures to avoid recurrence.

- Already in the contract and design stage, specify the operating modes of a ship’s machinery.

- For ship safety, arrange redundancy.

- Ensure appropriate backup power supply to automation.

- Take fuel pressure peaks and hot surfaces seriously.

- The root cause of a malfunction or issue may be very different from what you first think.

- Install automatic features only where a sensor failure cannot cause a critical situation and danger.

- Ensure vital equipment have local control and can be managed by the crew.

- Arrange regular training for the crew to ensure they can take local control when remote connection cannot be used.

- A small relay can stop a big ship.

- Essential functions like main switchboards should be split in two different rooms, for redundancy.

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.