The internal combustion engine stands out as one invention that has transformed every facet of human life. Over a hundred years after its invention, it still stands tall as the primary driver of industry and transportation across the globe.

Yet, as the world grapples with the effects of climate change, there are concerns about the internal combustion engine’s contribution to global warming. Historically, improvements to the design have focussed on maximising its power and torque, with little innovation when it comes to improving its eco-credentials. But this trend is changing, and fast. That has a lot to do with how ubiquitous it is especially in the maritime industry.

“There are not many viable alternatives to the internal combustion engine,” declares Lucien Koopmans, Professor and Head of Division for Combustion and Propulsion Systems at Chalmers University, Sweden. “Electric motors are an option where minimising emissions and particulate matter is important – in regulated areas, entering and exiting harbours – but giving up cargo space, and weight, for battery space is the big issue if longer distances need to be covered.”

“We still need the internal combustion engine. It’s the best we have in our path towards sustainable shipping. In fact, it is possible today to power a ship and have close to zero emissions with today’s alternative energy and clean-burning solutions,” claims Fredrik Östman, General Manager Wärtsilä Marine Business, Strategy & Business Development.

How can this be done? The trick, says experts, is to find a way to reduce greenhouse gases emitted by these engines through the use of alternative fuels, and smarter, more efficient means of combustion.

Improving upon established designs

“Our focus is to optimise the efficiency of the combustion processes as much as we possibly can, together with various low carbon fuels like biofuels, ammonia, hydrogen and methanol,” explains Östman. “Applying these kinds of minute and advanced controls to the combustion process has only been possible in the last decade or so with advances in combustion control and computer modelling.”

As the climate debate has heated up, more research has been applied to studying the minutia of the actual combustion process down to the atomic level, and what happens to different fuels and their thermal efficiencies when combusted at different pressures and physical states.

“As computer power has become cheaper and more sophisticated, much of our efforts focus on modelling combustion parameters like turbulence and chaos with different fuels and application types, like spray and atomisation in order to increase the thermal efficiency (output/input) of engines big and small. And usually, the bigger the engine, the higher efficiency you can get,” says Koopmans.

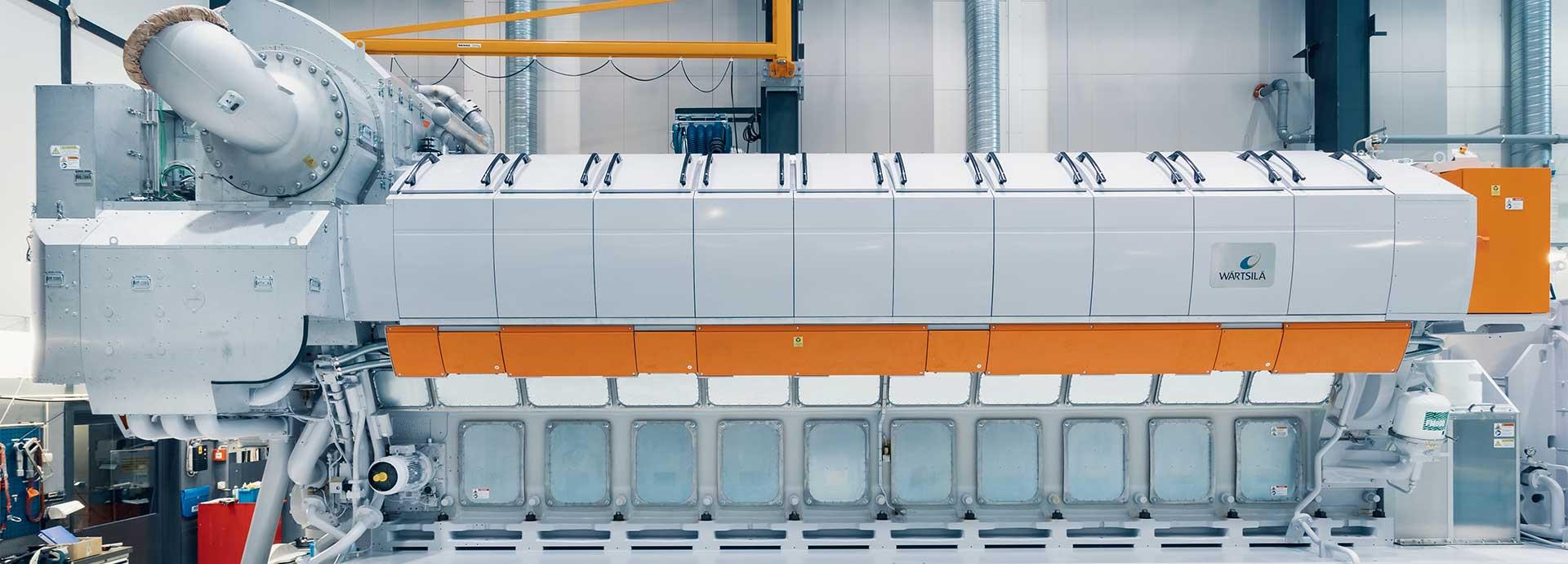

The holy grail is reaching 60 percent efficiency, according to Koopmans, which isn’t too far off. Wärtsilä holds a Guinness Book of World Records title for its Wärtsilä 31 engine, the most efficient 4-stroke diesel engine in the world, with more than 50 percent fuel efficiency.

“It really boils down to an economic argument. Will there ever be a fuel as cheap as HFO? Every alternative we know of requires a lot of expensive processes to make them viable for combustion at scale. Since the supply of biofuels will be limited, industries like aviation with a capability to pay more for the fuel will likely gobble up whatever is available.”

But says Östman: “Economics is indeed important, but the price of HFO is irrelevant if there is emission legislation in place that forces the industry to move towards alternative fuels. So given strict emission regulation on green-house gases, the relative cost of the alternative fuels is what will be important.”

The search for alternative solutions

One fuel that is gaining traction worldwide, however, is liquefied natural gas, or LNG, with bunkering facilities currently being built around the world to harness dual-fuel (DF) capabilities.

“There is nothing that the internal combustion engine does with HFO that cannot be done with LNG,” says Östman. “LNG contains no sulphur, making compliance a piece of cake. The reality is that the combustion engine really doesn’t care about the fuel. As long as it burns, we can use it in our engines.”

“Carbon-neutral fuels like synthetic LNG seems today to be the most economically viable for the shipping industry to become sustainable. But at the same, it’s also clear that there will be a large palette of fuels with large local variations in availability. So, what we need to focus on is fuel flexibility. Testing different fuels is a core element of our business, which we continuously do. A large set of various biofuels, hydrogen and methanol have been tested for years in our engines. We’re currently also investigating what it means to use ammonia as a fuel. What strikes us time and time again is that the combustion engine is extremely fuel flexible and only minor changes are needed to adapt it to new fuels. A lot of the needed infrastructure is already in place, the technology is mature and safe, and we have the needed regulations in place – along with years of experience!”

While work finding cleaner fuels and exotic new technologies continues, it is clear that it is the internal combustion engine that will remain the mainstay of the maritime industry. And with efforts to improve its efficiency continuing, it is the best placed to enable the transition to the low-emission future that the sector is desperately searching for.

“The combustion engine remains the stalwart of shipping because it enables fuel flexibility leaving the doors wide open for the future renewable liquid and gaseous fuels as and when they become compliant, market-ready and available,” says Östman.

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.