Future proof: Wärtsilä solutions mean the Fure Viten is ready for 2050 – today

Shipowners around the world are looking at how to meet the emissions targets set by the IMO in the Energy Efficiency Design Index (EEDI), which promotes the use of more energy-efficient equipment and engines by requiring a minimum energy-efficiency level per capacity mile. This requirement is tightening every five years in order to meet the IMO’s goal of a 50% reduction in shipping emissions by 2050. While many in the industry are finding these targets challenging, they’re child’s play for Furetank’s newest tanker the Fure Viten, which left the shipyard in June 2021 with the 2050 target already met.

Furetank is a family-owned company that operates from the picturesque surroundings of Donsö, a small island with around 1,500 inhabitants located just off the west coast of Sweden. The island is famous for its tanker companies, with no less than ten working side by side on the island – despite the fact that many of their massive vessels can’t even dock in Donsö’s tiny harbour. In this small and scenic corner of the world, Furetank is setting an example for global shipping when it comes to meeting emissions targets.

World-leading tanker design

Nowhere can this be seen more clearly than in the Fure Viten, a 17,999-dwt tanker with a cargo capacity of 20,300 cubic metres, designed by Furetank and FKAB Marine Design in collaboration with Wärtsilä. The vessel was one of eight tankers built with the aim of minimising fuel consumption; Furetank owns four and operates the other four on behalf of the tanker companies Älvtank and Thun Tankers, both from mainland Sweden, and the Canadian operator Groupe Desgagnés. All four companies are members of the Gothia Tanker Alliance, which based on their experience so far has already commissioned another two vessels – one for Furetank and one for Thun Tankers.

All eight vessels have been designed to run on liquified natural gas (LNG) and they all fulfil the IMO’s Tier III requirements. “We can see that LNG is the cleanest fuel you can find on the market today and the best option if we are to use this vessel for the next 20 years,” says Lars Höglund, CEO of Furetank. But Furetank also hopes to go one step further, running all eight tankers on bio-LNG as soon as 2030 and completely eliminating the use of fossil fuels.

Our plan is to use a fuel blend with 10% bio-LNG initially and gradually increase this in line with the fuel’s availability, eventually operating on 100% bio-LNG by 2030.

To do this, Furetank has made an exclusive agreement with a supplier to secure a sufficient quantity of bio-LNG. For Höglund, it was a no-brainer to work with Wärtsilä on the dual-fuel engines: “If you look at the market for dual-fuel marine applications, the company with the most experience is Wärtsilä,” he observes.

A holistic approach to optimisation

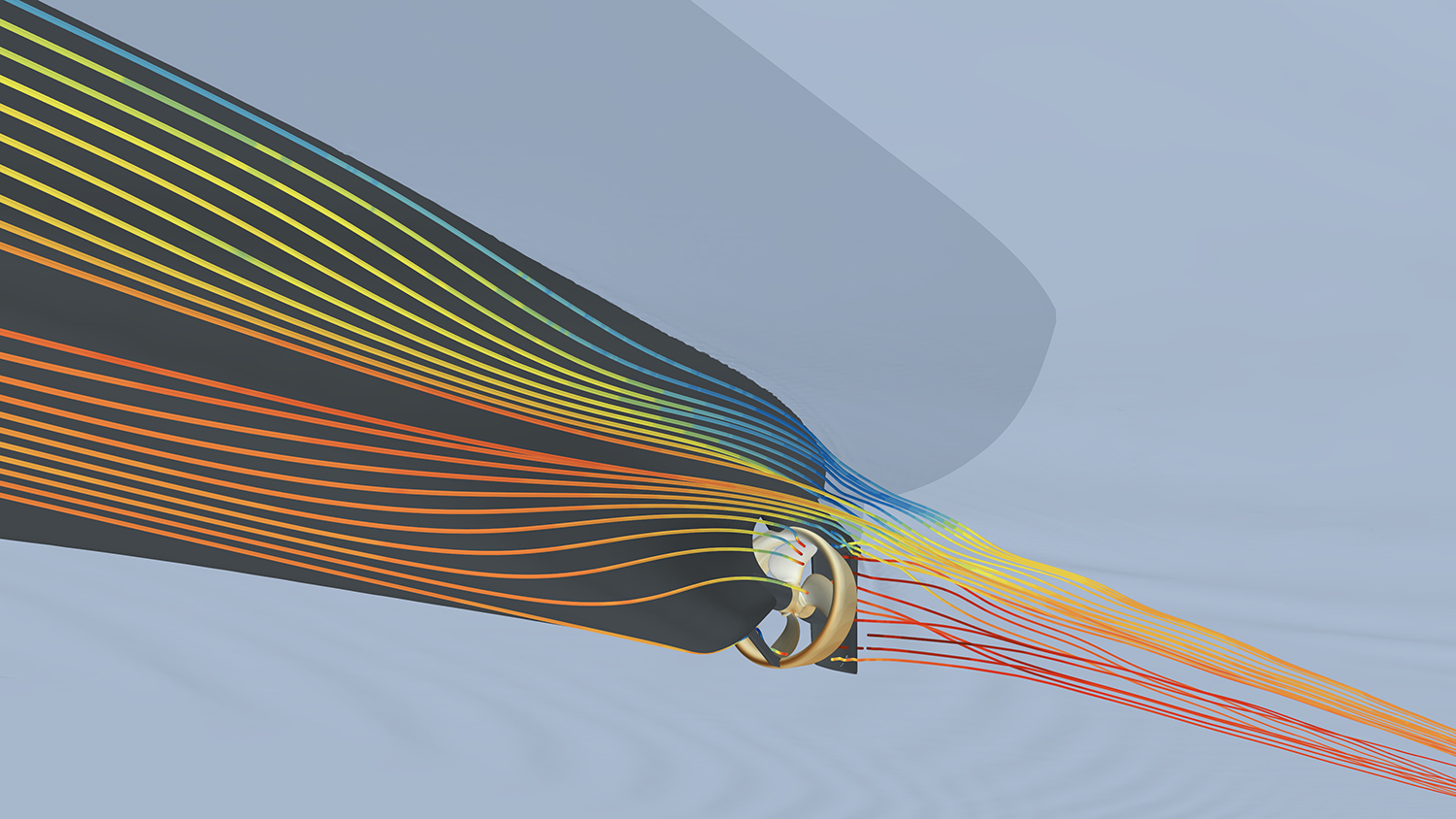

While LNG was the obvious fuel choice, finding other ways to reduce emissions while maintaining performance required a great deal more expertise. Furetank worked with Wärtsilä to install a range of energy-saving solutions, employing Wärtsilä’s OPTI Design approach to achieve optimal propulsion efficiency. OPTI Design uses computational fluid dynamics (CFD) to optimise the performance of the propeller, nozzle and rudder, looking at how they interact with the vessel’s hull to create a design that optimises the different elements. Wärtsilä is the only company in the world that can offer such a comprehensive scope of marine solutions from its own portfolio and then integrate them in the ship’s design phase to ensure optimal overall performance. Throughout the design and construction process, energy efficiency was increased and the EEDI value improved.

CFD simulation for propulsion optimisation, including Nozzle, CPP and EnergoPac.

CFD simulation for propulsion optimisation, including Nozzle, CPP and EnergoPac.

Gas-powered engine with extremely high reliability

The Fure Viten is powered by the Wärtsilä 34DF dual-fuel main engine and has two Wärtsilä Auxpac auxiliary engines onboard fitted with a selective catalytic reduction (SCR) system to reduce emissions. The vessel also has a backup battery that can take over from the auxiliary engines when sailing through narrow channels – a first for a tanker of this size. This battery means the tanker can operate solely on its main engine far more often than similar vessels; it also prevents blackout if the main engine shuts down, minimising auxiliary engine use. The vessel also has highly efficient electric cargo pumps that use 15–20% less power than hydraulic pumps and are also much quieter. These pumps optimise the operating point of the main engine when it’s being used for discharging.

Furetank has been very happy with the operational reliability and availability of the engines and their ability to maintain gas operation even in harsh conditions. Furetank tankers often operate in rough seas, with one operating from the south of Norway to Iceland – a route known for its inclement weather and large waves. Hitting a large wave increases the torque rapidly, placing a large load demand on the engine, with a corresponding sudden reduction in load when coming down the wave. “Managing the route with a diesel engine is already challenging, with the engine load varying from 30–100% within seconds, so the operational reliability and availability we’re seeing with the Wärtsilä gas engines is nothing short of exceptional. This level of performance is better than anything else on the market today,” shares Höglund.

Energy-saving devices and future shore power

The Fure Viten has a ducted controllable pitch propeller that increases thrust by nearly 25% at low speeds and is compliant with ice class 1A. The propeller is fitted with a Wärtsilä High Performance Nozzle that further improves thrust and increases propulsion and fuel efficiency. The final energy-saving device onboard is a high-efficiency Wärtsilä EnergoPac rudder system – a proven technology that increases manoeuvrability while further reducing fuel consumption.

During discharging, the main engines run on LNG with reduced rpm and are used as generators. They drive the shaft generator and the propeller is disconnected and at a standstill. Fure Viten and her sister vessel Fure Vinga are also the first tankers in Europe that can operate their electrical power consumption and cargo pumps with 6.6 kV high-voltage shore power, offering an opportunity to reduce emissions even further as soon as ports can accommodate this option. The ports of Gothenburg and Rotterdam are currently in the process of developing the connection required to supply ships with electric power from shore, further increasing the environmental performance of the tankers as emissions in port can account for up to 20% of a tanker’s total.

Savings that add up to a world-class result

The vessels were designed to use around 40% less fuel when sailing compared to Furetank’s previous tankers and about 50% less fuel when manoeuvring. They were also designed to reduce SOx emissions by 99%, NOx by 80% and CO2 by 50%. However, sea trials proved the environmental credentials were even more impressive, with CO2 emissions reduced by 55%, NOx by 86% and SOx and hazardous particulate matter (PM 2.5) emissions virtually eliminated. This last point in particular is worth highlighting because of the significant health and economic impacts of PM emissions generated by shipping, which include respiratory illness in humans and damage to agricultural crops.

Vessels the size of Fure Viten are required to have an EEDI value of below 9.37 – the lower the EEDI value the lower the emissions. Measurements taken by an independent third party during sea trials and verified by the class society Bureau Veritas saw Fure Viten score 4.65 points – the best result ever achieved for a vessel of its size and comfortably below the IMO’s 2050 emissions reduction target. This represents a 50% reduction in CO2 emissions over similar-class vessels built between 2002 and 2012.

In April 2022 it was announced that Furetank had become the first shipping company in Sweden, and only the second company overall, to be granted a green credit guarantee by the Swedish Export Credit Agency for financing a vessel of top-class environmental and climate standard. The approval is pioneering for shipping, enabling vast investments in the green technology required to achieve European climate goals. The guarantee applies to the pre-financing of Furetank's next product and chemical tanker.

Since the Fure Viten and her sister ships will be operated for the next 20 years, they have been designed accordingly, and Furetank are extremely happy with the results so far. The delivery of Fure Viten has reduced the average CO2 emissions for Furetank’s fleet by 50% compared to 2008 levels. This demonstrates what is possible with a holistic approach to efficiency improvement and vessel design. Indeed, the Gothia Tanker Alliance, of which Furetank is a member, has been so impressed that it has commissioned another two vessels fitted with Wärtsilä main engines, gearboxes and controllable pitch propellers to further support their drive to reduce emissions.

Watch our webinar to learn more about Wärtsilä energy-saving technologies