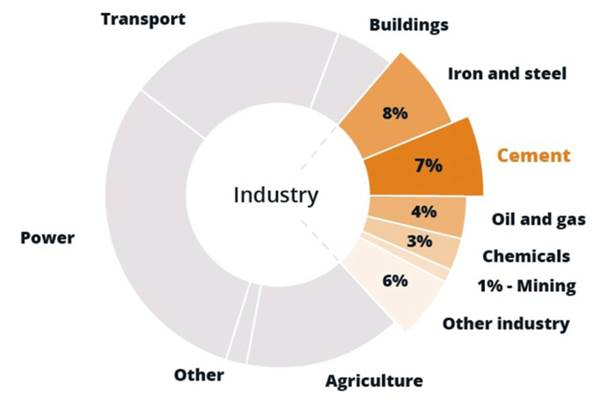

The cement industry is responsible for approximately 7% of global CO2 emissions today. In Africa, the challenge is particularly pressing as the continent's cement capacity is expected to increase by 77% by 2030.

Decarbonization is crucial for sustainable development, ensuring power availability while maximizing renewable integration through an optimal mix of thermal and renewable energy sources.

The Need for Decarbonization in the Cement Industry

Current Challenges: The production of each ton of cement results in approximately 0.6 tons of CO2 emissions. As sub-Saharan Africa's cement capacity is poised to expand significantly over the next decade, an additional 250 MTPA of cement production capacity could lead to an increase of 150 Million tons of CO2 emissions annually. This potential rise in emissions is larger than the current carbon footprint of Nigeria, one of Africa's largest economies.

Importance for Africa: Developing Cement industry in Africa with Decarbonization in mind is crucial not only to meet the continent's burgeoning infrastructure demands but also to tackle pressing environmental challenges and align with global climate objectives. Embracing sustainable practices is essential for ensuring long-term economic resilience and environmental stewardship, safeguarding the future of Africa's communities and ecosystems.

The Role of Internal Combustion Engines

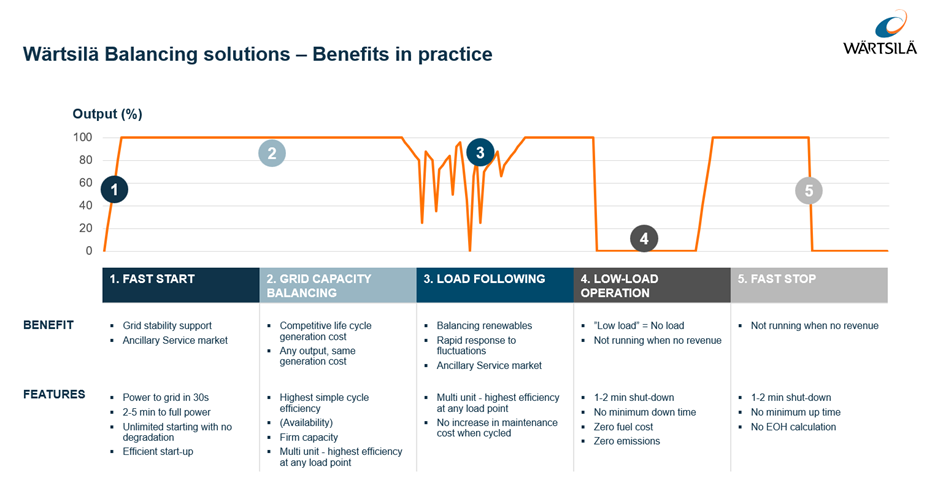

Internal combustion engines (ICEs) are pivotal in the transition to a decarbonized cement industry in Africa. These engines offer unparalleled flexibility and efficiency in power generation, achieving open cycle efficiencies of 45-48%, which surpasses the performance of gas turbines and high-speed engines. Their modular design allows for high ramping rates, unlimited free start/stop cycles, and the ability to adjust loads dynamically, making them ideal for balancing renewable energy sources with best-in-class dynamic capabilities.

Wärtsilä's ICEs are particularly well-suited for hybrid power systems due to their ability to operate efficiently at varying loads and their rapid response to changes in energy demand. This flexibility is crucial for integrating intermittent renewable energy sources such as solar and wind, ensuring a stable and reliable power supply even when renewable output fluctuates.

Moreover, ICEs can run on a variety of fuels, including natural gas, heavy fuel oil, and even biofuels, offering a pathway to gradually reduce carbon emissions as cleaner fuels become more available. This fuel flexibility not only enhances energy security by reducing dependency on a single fuel source but also supports the transition to more sustainable energy solutions.

In the context of Africa's energy landscape, where grid reliability can be a challenge, ICEs provide a robust solution for captive power generation. They enable cement producers to maintain consistent operations, reduce carbon footprints, and adapt to the continent's diverse and evolving energy needs. By supporting a diverse energy mix, ICEs empower cement producers to navigate the complexities of energy demand and resource availability, ultimately contributing to a more resilient and sustainable industrial sector.

Designing Hybrid Captive Generation Systems

Designing an effective hybrid captive generation system involves a strategic blend of thermal and renewable energy sources, tailored to the specific needs of each cement plant. These systems typically include:

- Thermal Assets: These provide a reliable power base, covering total peak load requirements. Internal combustion engines are often favored for their flexibility and efficiency, ensuring consistent power supply even in fluctuating demand scenarios.

- Renewable Assets: Solar, wind, and hydro resources are integrated based on available space and optimal capacity factors at the location. The inclusion of renewables is essential for reducing emissions and operational costs.

- Battery Storage (Optional): Energy storage systems can be incorporated to enhance grid stability and store excess renewable energy for use during peak demand periods or when renewable output is low.

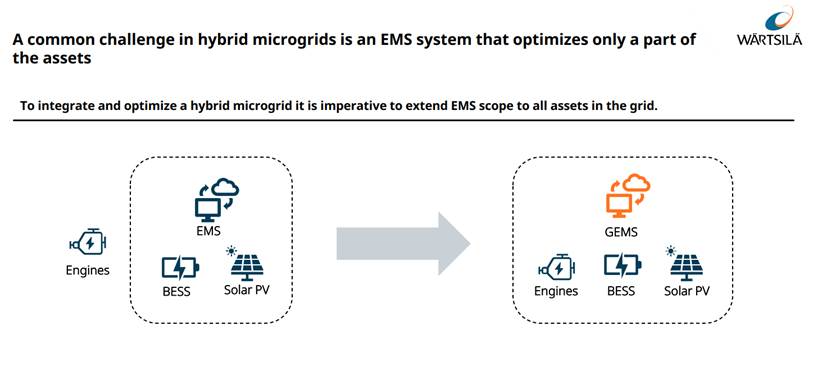

- Energy Management System: Advanced energy management systems play a crucial role in coordinating the various energy sources. By leveraging technologies such as AI and machine learning, these systems predict energy demand and supply fluctuations, ensuring optimal performance and efficiency. They enable real-time monitoring and control, allowing for seamless integration of renewables and efficient utilization of thermal assets.

The design of hybrid systems must consider local regulations, fuel availability, and logistical challenges. By optimizing the mix of energy sources and employing advanced management systems, hybrid captive generation systems can significantly enhance the sustainability and reliability of cement production. These systems not only reduce carbon emissions but also provide a cost-effective solution for meeting the energy demands of Africa's growing cement industry.

Concrete examples of industrial decarbonization projects in Africa

Fekola Gold Mine, Mali: At the Fekola Gold Mine, a comprehensive hybrid power solution was implemented to enhance energy reliability and sustainability. The system includes a 64 MW thermal power plant complemented by a 30 MW solar photovoltaic (PV) installation. Additionally, a 17 MW battery energy storage system is integrated to optimize energy use and provide stability. This combination significantly reduces fuel consumption and CO2 emissions, resulting in a more stable power supply that optimizes operational efficiency and supports the mine's production goals.

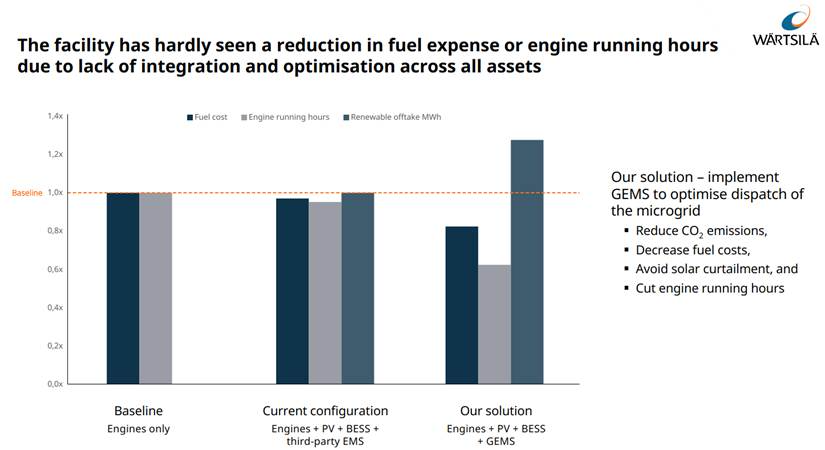

QMM - Rio Tinto, Madagascar: In Madagascar, Wärtsilä has partnered with QMM, a subsidiary of Rio Tinto, to support its power generation decarbonization. Wärtsilä’s offering focused on optimization of integration of 20 MW of solar PV with existing thermal generation assets. Our scope included a battery energy storage system (BESS) and our in-house Energy management System (GEMS) that contributed to the maximization of renewable integration and optimization of thermal power assets leading to a significant reduction of both engine running hours and fuel consumption.

Let's Collaborate on Africa's Cement Decarbonisation Journey

The future of Africa's cement industry lies in embracing decarbonization through innovative hybrid power solutions. With Wärtsilä's cutting-edge internal combustion engines and decarbonization offerings leading the way, stakeholders have a unique opportunity to transform the industry. By adopting these solutions, we can ensure a balance between reliability and sustainability, paving the way for a more industrialized and self-sufficient Africa.

Decarbonizing the cement industry is not just an environmental imperative; it's a strategic opportunity to unlock Africa's vast potential. As we move forward, the challenge is clear: How can we accelerate this transition to create a more equitable and prosperous future for the continent?

Together, we can drive meaningful change and build a resilient energy future for Africa. Let's seize this opportunity to lead the way in sustainable development.

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.