The Baltic sea is one of the most important trade routes in the world, and even today, at any time, nearly 2000 vessels are operating along this route carrying general cargo, liquid bulk and dry bulk. Over 400 ports dot the different regions surrounding

the sea, with at least 90 of these playing a significant role in international trade.

Experts estimate that over 50% of the vessels operating along this route are general cargo vessels, with another 20% being tankers carrying oil. Even the pandemic seems to not have dampened trade volumes with most Baltic ports reporting relatively stable numbers. But that is not to say that this maritime route does not have its share of challenges.

Any kind of shipping that takes places along this route has to contend with rather treacherous conditions including narrow straits, scattered landmasses and most importantly, ice. The waters of the Baltic sea and the surrounding Arctic regions are usually

covered in ice throughout the year, leaving limited windows for vessels to traverse the route safely.

All this makes shipping in the region a uniquely challenging proposition, with ships having to be designed to special ice-class

standards to be able to survive the journeys.

Purpose-built for the Baltic Sea.

The Lady Hanneke is one such ship. Operated by Netherlands-based shipping company Wijnne Barends, the vessels undertakes trips between the Arctic regions of Arkhangelsk in Northern Russia to St. Petersburg, almost always in near-frozen conditions. Needless

to say, this requires the vessels to be equipped with features that other vessels do not have.

“Our normal sailing routes are in Northern Europe and Russia with voyages taking upwards of 9 to 10 days, depending on weather conditions,”

explains Roman Bobrov, Chief Engineer of the Lady Hanneke. “There is a lot of ice during wintertime in certain ports especially Arkhangelsk. So, for this, we need to be sure that the ship is built to be ice-class with thicker

hulls, rudder and propeller protections. The Lady Hanneke is an ice-class 1A.”

The addition of these extra protections makes vessels like the Lady Hanneke capable of travelling down the Baltic sea, even during winter conditions with

icebreaker assistance. However, this also means that the vessel needs extra power to carry the additional weight, while still maintaining speed and efficiency. This is when Wijnne Barends turned to Wärtsilä to solve that particular challenge.

“Wijnne Barends is a very significant client for Wartsila because they operate a fleet in ice-class area and it requires a lot of liability and fuel efficiency,” explains Luuk Hijlkema, Senior Account Manager at

Wärtsilä. “This is important because the vessel should be reliable. Also, it is very important, of course, to meet future greenhouse gas norms.”

Sailing in eco-sensitive zones

Low greenhouse gas emission (GHGs) are a crucial element for Wijnne Barends especially considering the eco-sensitive nature of the Baltic sea. The region is home to various unique flora and fauna and is governed by some of the most stringent environment

norms in the world. Any vessels operating here needs to keep its emissions in check, while ensuring the least possible emissions footprint.

This is normally a Catch-22 for most fleet owners and operators who find it difficult to balance

a reduction in emissions, while ensuring that a vessel is able to maintain its speed. Higher fuel efficiency normally equals reduced speeds which in turn can affect the profitability of a route. Keeping all this in mind, Wärtsilä produced

a solution that met Wijnne Barends’ requirements and more.

“The initial request from Wijnne Barends was to develop a solution for a vessel which required by St. Petersburg port authorities for a 2000 kw propeller,” recalls

Hijlkema. “However, with our experience of being a complete marine systems integrator, we realised that only half this power was really required.”

“We used an integrated systems approach to develop a complete drive train

that would look at all aspects of the vessel, right from engine to propeller, to see how the vessels is being operated and develop a solution that would meet all real-life operating conditions and challenges,” adds Hijlkema.

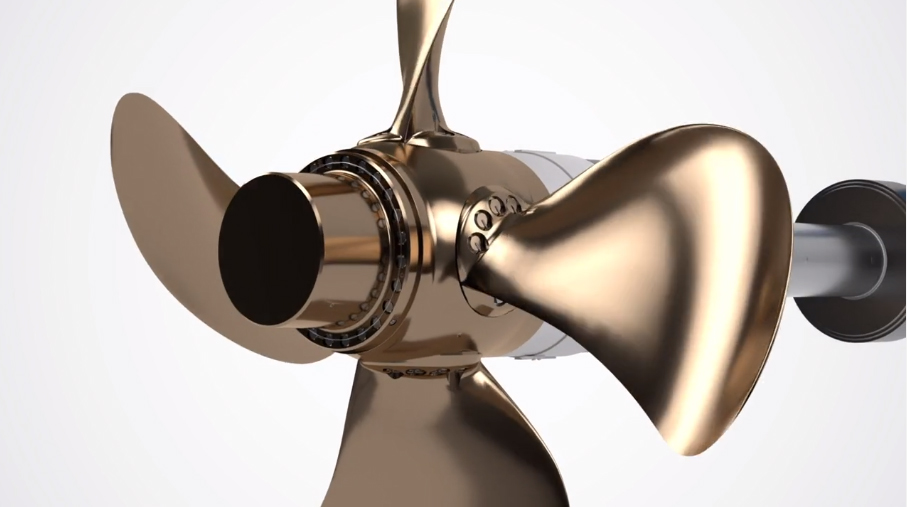

An integrated approach

Wärtsilä’s Controllable Pitch Propeller (CPP) proved to be the best solution to meet these challenges. Its hydrodynamic design allows for improved propulsion efficiency, resulting in improved speed, reduced fuel consumption and better

manoeuvrability.

The integrated approach saw the Lady Hanneke being equipped with a host of cutting-edge solutions including the CPP, an eco-mode for the engine to improve fuel efficiency without losing speed, a battery pack to handle different

load variations thereby enabling the vessels to deal with constant loads, and a unique gearbox solutions to help improve engine operations and lifetime.

“The most important bit is the eco mode of the engine. The engine is now able

to run with reduced RPM, resulting in improved fuel economy. And the results show that running on the booster mode gets fuel economy compared to other vessels with the same tonnage without losing speed,” says Bobrov.

“It

is more flexible because if we need more power sailing in the ice, we can always connect the auxiliary engine for the propulsion. So, it gives us very good fuel consumption and normally we are trying to use eco mode as much as possible to save

the money, save the fuel and save the nature,” he adds.

The result was a huge success. Approximately 45 tonnes of fuel have been saved, along with a reduction of 145 tonnes of CO2 emission per year which is approximately 4% fuel savings

achieved compared to other similarly designed vessels. This is on top of the benefits of using a smaller power engine in the propulsion train.

“The CPP system lets us operate and easily adjust our speed to reach good economy,

to reach good time arrival and, of course, during a bad weather and during manoeuvrings,” explains Bobrov.

Wärtsilä’s CPP and other related technologies are now being equipped on the 6 ships that belong to the Lady

Hanneke class, heralding a new era for maritime transport and trade in the Baltic sea.

“We have had good experience from working together with Wärtsilä. They are always there to solve the problems which appear suddenly

and they them quick and fast. So, in my opinion, it is a good team – Wijnne Barends and Wärtsilä,” concludes Bobrov.

Related solutions

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.