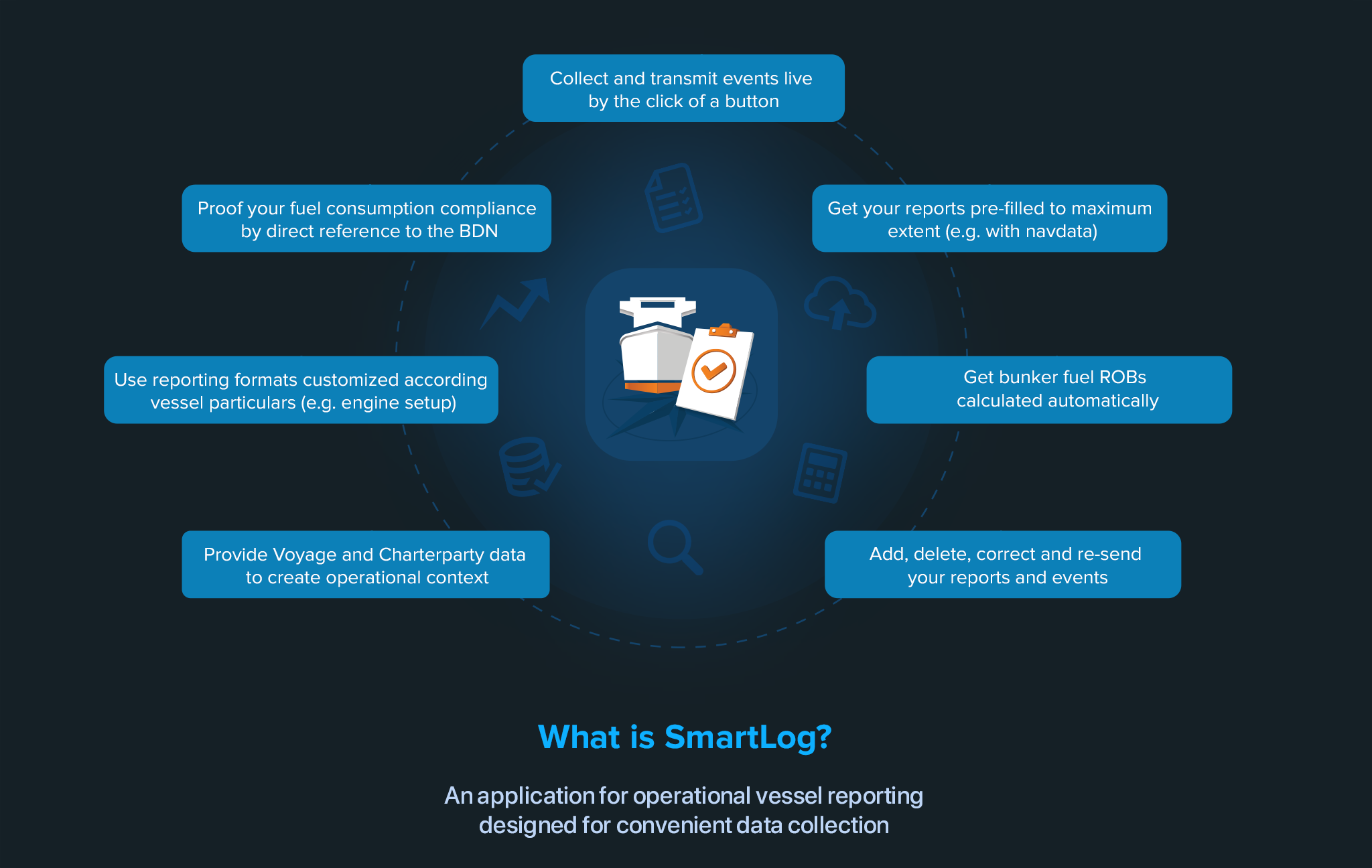

Whether you are auto-logging vast quantities of sensor output or relying on the traditional noon report, ships are a data goldmine. But feeding data to the growing number of off-vessel demands – from performance management to charter party and environmental compliance – is an increasing bureaucratic burden. SmartLog is the missing link between vessel data and streamlined reporting. It is also a key part of unlocking the full value of data analysis.

SmartLog is part of Wärtsilä Voyage’s Fleet Operations Solution (FOS). At its simplest, FOS integrates a vessel’s ECDIS (electronic chart display and information service) and navigation planning stations. This basic configuration already provides with a range of voyage optimisation and navigational safety features. Even greater value is unlocked with the integration of reporting, as this extra data allows for further optimisation, monitoring and reporting functions. These additional benefits are enabled by SmartLog.

“Crews spend most of their time filling out numerous reports for all sorts of people,” says Kay Dausendschoen, Solutions Director, Wärtsilä Voyage.

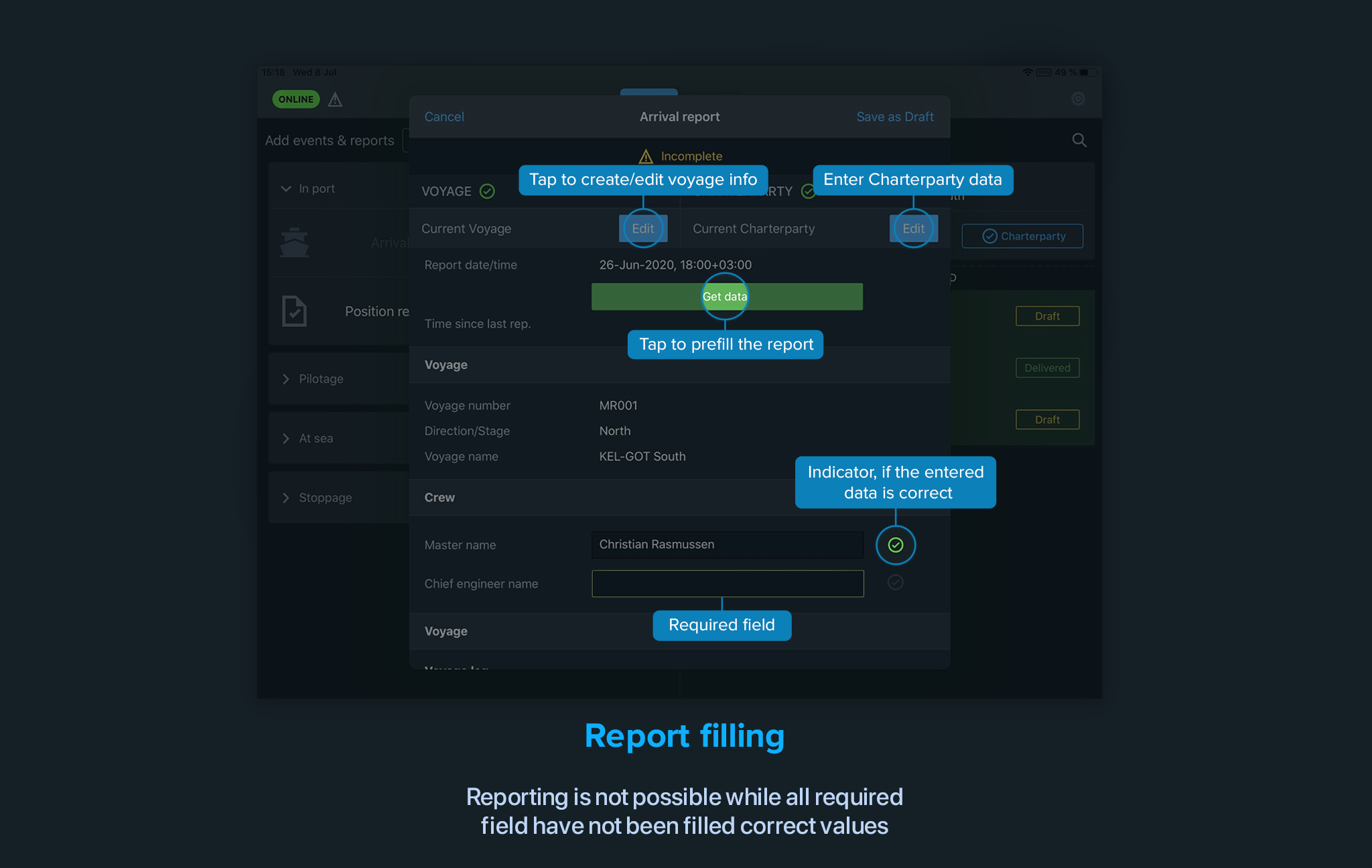

We have a lot of data already from the bridge equipment. We also know the voyage and vessel details. That’s half of the data needed for each of these reports. SmartLog pulls the data together from all those sources and pre-fills the reports.

- Kay Dausendschoen, Solutions Director, Wärtsilä Voyage

That pre-filling function alone makes SmartLog a valuable tool, cutting in half the time required to fill in the noon report. Time is also saved by automating the output as well as the input; once a report is received in the office, SmartLog can direct it automatically to the correct stakeholders.

Automated reporting

Automating the reporting process will become even more valuable in the future. Ships’ crews must already provide regular reports to charter parties and owners, among others. But reporting demands are increasing. Recently the European Union required that operators provide fuel consumption and cargo information under the Monitoring, Reporting and Verification (MRV) regulation. IMO requires similar information for its Data Collection System. Future requirements will be even more onerous, whether it is the continuous monitoring required for vessels equipped with scrubbers or the emission monitoring that will underly shipping’s inclusion in Europe’s Emission Trading Scheme or IMO’s impending Carbon Intensity Index.

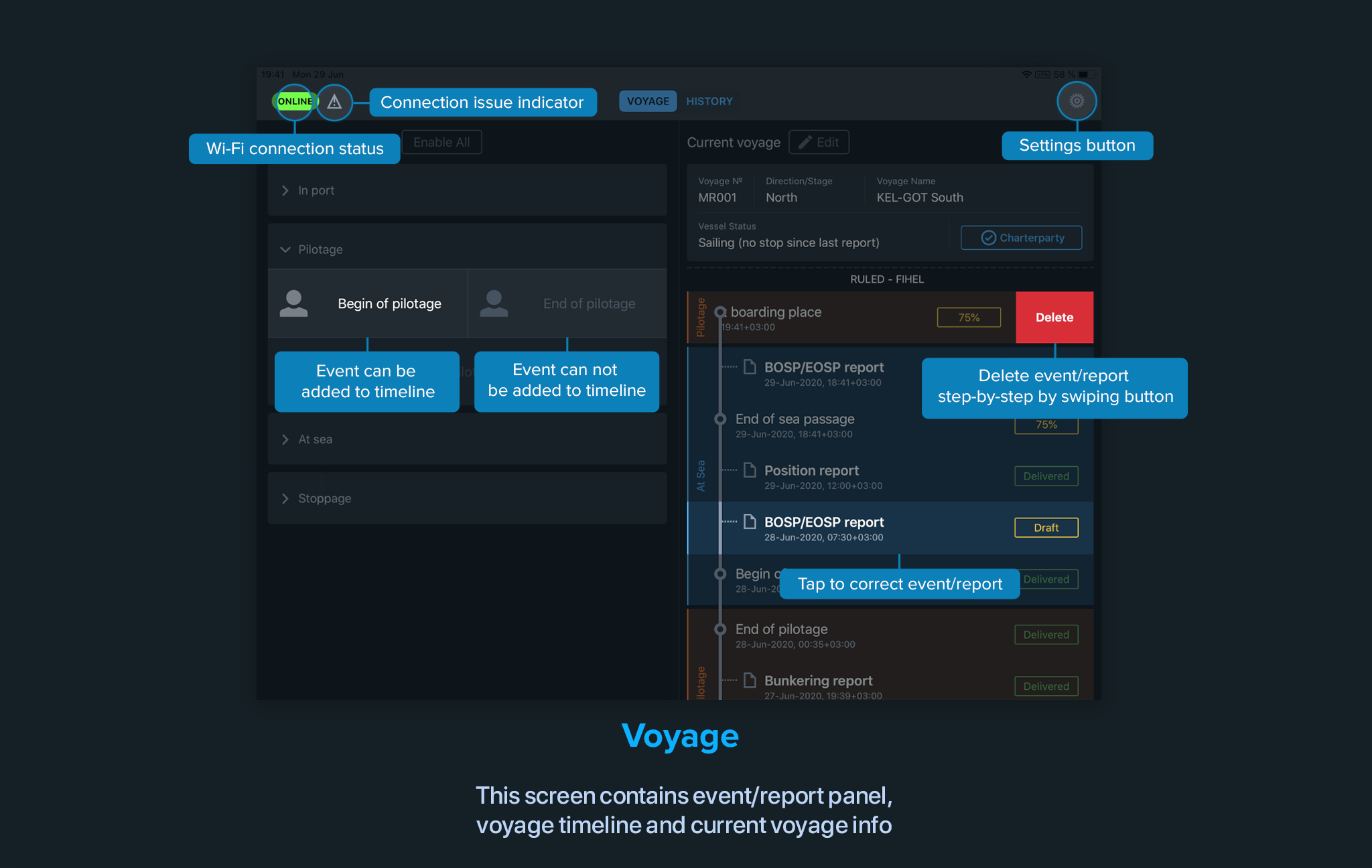

Other features of SmartLog make the tool even more valuable for reporting. One example is the ability to log and time-stamp particular events and transmit the information in real time. This function is particularly useful for showing when vessels are moving from one regulatory jurisdiction into another where different fuel types or equipment may need to be used. SmartLog can therefore notify crew and record when the vessel needs to switch to low-sulphur fuel when entering an emission control area, for example, or when entering port jurisdictions that may have their own requirements on the use of fuel or equipment.

Automated reporting also offers significant improvements to the quality of data as well as the time taken to compile it. This is of critical importance when it comes to using the data as a basis for further analysis. SmartLog ensures that data is standardised where relevant across forms – and that the date inputs are relevant to the vessel and its operation.

Dausendschoen explains: “Once the app is connected to the bridge, it has access to the vessel’s master data and knows what kind of animal it is working with. Whether it is fuel types or cargo units, the SmartLog flexibly adjusts to vessel and even company requirements.”

This built-in logic also means that new data is constantly verified compared to previous data to eliminate any gaps or errors. For example, fuel reporting traces back to when and where the fuel was bunkered and used to make sure the type and quality is accounted for consistently.

Added-value analysis

Reporting is dramatically improved by SmartLog. But that is just the start. After SmartLog has collected the data and transmitted it ashore, that same data is used to offer further functionality via FOS. Logged data is used in the performance modules of the FOS dashboard and processed in the cloud to enrich various performance analytic features. Smart algorithms use this data to create dynamic, high-accuracy digital twin performance models.

For the nautical and safety modules, the data we have from the bridge systems does not need to be enriched with reported data,” Dausendschoen says. “For everything else that FOS can do in terms of performance management and voyage optimisation, we need SmartLog. It brings the fuel component which is directly related to efficiency, and that is arguably the most important value in FOS.”

From fuel consumption and efficiency, ship companies are able to accurately monitor and optimise the performance of their engines, for example. Or understand the impact that hull fouling has on their fuel consumption. Or work out how changing route based on weather conditions will affect consumption. All these elements are enabled by the free flow of verified, standardised data from SmartLog through to the various FOS software modules. Other functions that rely on the exchange of standard data – communication with ports for example – also rely on SmartLog’s functionality. This will become increasingly important as just-in-time arrivals become a more widely adopted practice to improve efficiency and reduce emissions at port.

SmartLog is valuable enough as an automated, pre-populating report tool that can remove administrative burden from ship crew and office staff. But it is also a building block of the more sophisticated functions offered by FOS. And as the demands of ship owners and regulators become increasingly complex, this powerful tool will undoubtedly become the basis for ever more exciting and valuable ways to use vessel data.

Know more about Wärtsilä SmartLog

Related solutions

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.