A Power Plant Controller (PPC) is one of the most important pieces of software for battery energy storage systems (BESS) to comply with grid code and participate in lucrative markets.

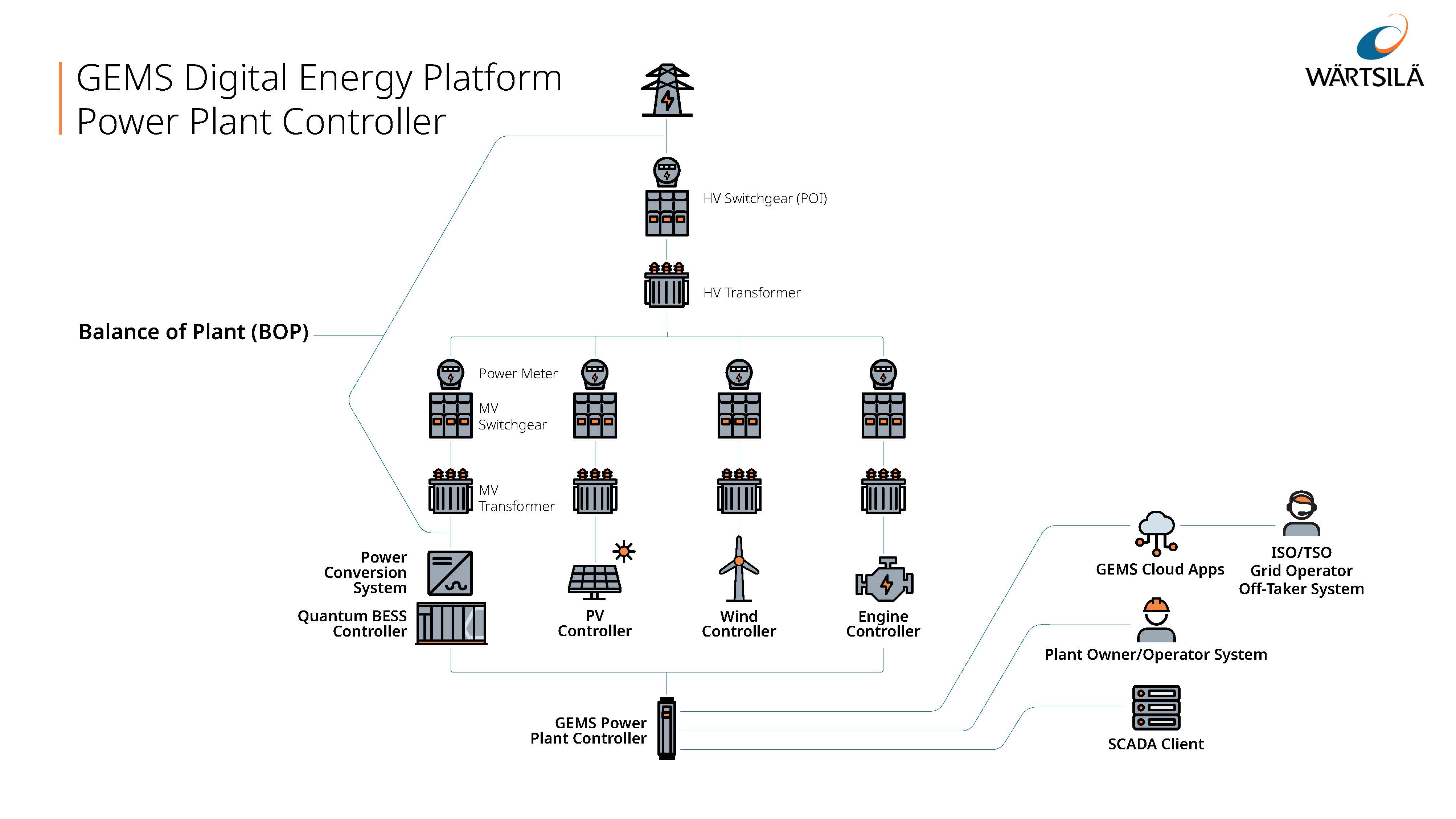

Many energy storage facilities are co-located with other generation assets like solar, wind, or engines. While each generation asset has its own individual controller, the PPC provides control across all assets at the plant level.

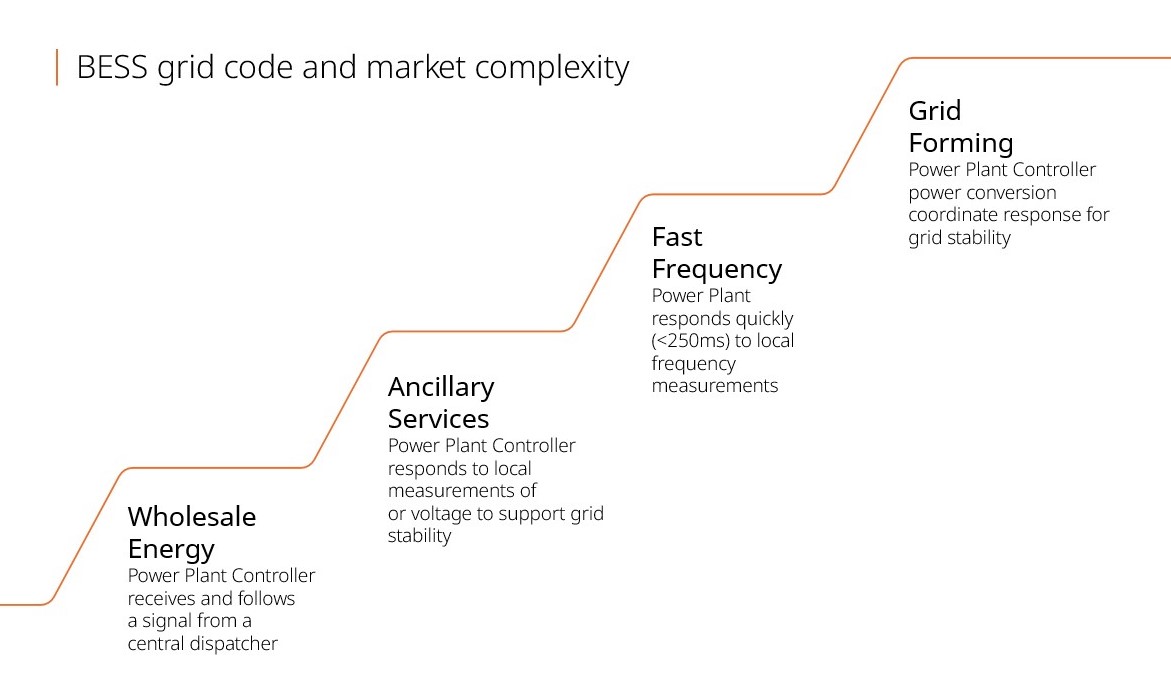

The increase of renewable energy penetration in global markets over the last few years is driving significant changes in grid codes and market requirements. Wholesale energy markets have the lowest level of complexity, in which the PPC follows a signal from a central dispatch without much extra processing. The next level of complexity is ancillary services, such as frequency or voltage support, which require the PPC to react to a local measurement of grid conditions. The next step up from that is fast frequency response, in which the PPC responds to local frequency measurements in less than 250 milliseconds. The highest level of complexity is grid-forming, which includes virtual inertia and short circuit contribution, where the PPC and power conversion system (PCS) coordinate to ensure grid stability.

What can an advanced PPC offer?

1. Closed loop control

Whether an energy storage facility is operating in a wholesale energy market or performing grid-forming services, the PPC must maintain accurate power at the point of interconnection. If not, there could be negative impacts to revenue and potential penalties.

The most reliable method for ensuring accurate power is using a properly tuned closed loop controller. Closed loop power allocation dynamically adjusts plant output to maintain power levels where it counts. The process starts with a power meter or transducer measuring the power at the point of grid connection. Then the controller adjusts the power setpoint for the BESS based on the error between the measurement and the desired target power. Next, the PPC distributes the total power among the PCS’s using a power allocation algorithm. Finally, each PCS delivers the requested power that came out of the distribution.

This process repeats continuously, with each iteration of the process happening more than 10 times per second. It happens so quickly that no disruption to the grid is detected when a PCS trips offline.

2. Fast frequency response

The PPC is critical to successfully participating in fast frequency response, whether it is from a different vendor or the same vendor as the BESS controller. However, using an integrated PPC and BESS controller system eliminates one step involved with fast frequency response.

The process of fast frequency response starts with the PPC receiving a frequency signal over the local network, usually from a meter located at the point of interconnection. Next, the PPC processes the signal, adds power from any other market it’s participating in, and adjusts based on the closed loop control feedback.

When the PPC and the individual BESS controller are provided by separate vendors, the total calculated setpoint is then sent to the BESS controller over the local network via an external network interface. The BESS controller receives the target from the PPC, processes the signal, applies its algorithm to distribute the power across the units, and then transmits a setpoint to each PCS. Finally, each PCS begins to respond and ramps up to the target power level. In this scenario, the process can take up to 260 milliseconds—but most responses need to be under 250 milliseconds to meet market requirements.

When the plant uses one integrated PPC and BESS controller system, no external network interface is needed to transmit the setpoint to the BESS controller. With all else being equal, now the process takes a maximum of 240 milliseconds. Aside from the speed implications, removing the external network interface also simplifies commissioning, operation, and maintenance.

Advanced PPC solutions can offer even more impressive results by taking advantage of modern software architecture to further reduce time it takes to process signals, calculate responses, and transmit commands to the PCS units.

3. Flexible and pluggable equipment drivers and operations

Flexible and pluggable architecture makes integration with equipment, power operations, and other applications seamless. The architecture of a PPC should be able to support pluggable equipment drivers to communicate with, monitor, collect data from, and control various site equipment as needed. New equipment drivers only need to be written using the protocol that the piece of equipment supports and plugged into the software configuration. The data collected through equipment drivers can be published through different interfaces like HMI, SCADA, and API and used for various purposes such as analytics, reporting, warranty purposes, and troubleshooting. In addition to equipment drivers, as markets evolve, new power operations logic must be developed and plugged into the software configuration to stay in compliance.

4. Enabling batteries state-of-charge calibration and cell balancing with automation

Automated state-of-charge (SoC) calibration and cell balancing is another important feature of an advanced PPC. One of the biggest challenges faced by traders and BESS operators today is how to accurately estimate the amount of capacity available in the battery at any given point in time. Accurate SoC estimations and well-balanced battery cells are critical to maximise the usable capacity of a site. Inaccurate estimations can lead to poor trading decisions such as selling too much or too little energy, which could result in decreased revenue.

An advanced PPC should be able to automate SoC calibration and regular cell balancing. Doing so reduces the manual labour required to sustain optimal operations and enables the system to stay in market when these actions are performed. This reduction in downtime and increase in usable energy has a significant impact on a system’s financial performance, further differentiating the long-term benefits of using sophisticated BESS software for your system.

There are many other benefits of advanced PPCs not detailed here, including but not limited to:

- Sophisticated power allocation algorithms

- Stacked power operations and limits

- Multi-tenant site control

- Multi-GWh BESS site support

- On-grid and off-grid transitions

State-of-the-art software architecture is necessary for an energy storage facility to remain competitive in today’s rapidly evolving landscape. The GEMS Power Plant Controller conducts intelligent power control and optimised energy management operations at 100+ power plants of all sizes, within dozens of markets globally as part of Wärtsilä’s controls and optimisation software, GEMS Digital Energy Platform.

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.