They help power some of the world’s biggest and fastest vessels. Find out why Wärtsilä’s waterjets have gained a reputation for being lightweight, powerful and durable.

At the Armon Gijón shipyard in north-west Spain, one of the world’s largest LNG-fuelled high-speed catamarans, a multi-hull watercraft featuring two parallel hulls of equal size is coming to life. Once completed, the 125-metre-long ferry will carry 1,200 passengers and 500 cars at speeds ranging from 35 to 40 knots or about 65 to 75 kilometres per hour.

Built for Spanish ferry operator Baleària, it is scheduled to start operations in the summer of 2020. The new ferry will “shape the future of high-speed, gas-powered catamarans and trimarans,” says Juan M. Paino, CTO at the Armon Gijón shipyard.

The new ferry is equipped with several Wärtsilä technology solutions, including four Wärtsilä LJX1500SRI waterjets, four Wärtsilä 31DF dual-fuel engines, LNG storage and supply systems as well as auxiliary systems. The storage tanks will allow the ferry a range of 400 nautical miles.

The combination of Wärtsilä dual-fuel engines and waterjets being commissioned to the same high-speed vessel is something that excites the waterjets team at Wärtsilä, especially since waterjets were not always considered a natural extension to the broad portfolio of marine technology solutions that Wärtsilä offers.

“Waterjets are commonly used in combination with high-speed engines, so a combination with the Wärtsilä 31DF engines is exciting,” explains Jeroen Vedder, Sales Manager, Waterjets at Wärtsilä.

However, the recent launch of the Wärtsilä 14 high-speed engine in 12 and 16-cylinder configurations has now opened up a plethora of new possibilities to offer complete packages including waterjets.

Midsize to modular jets

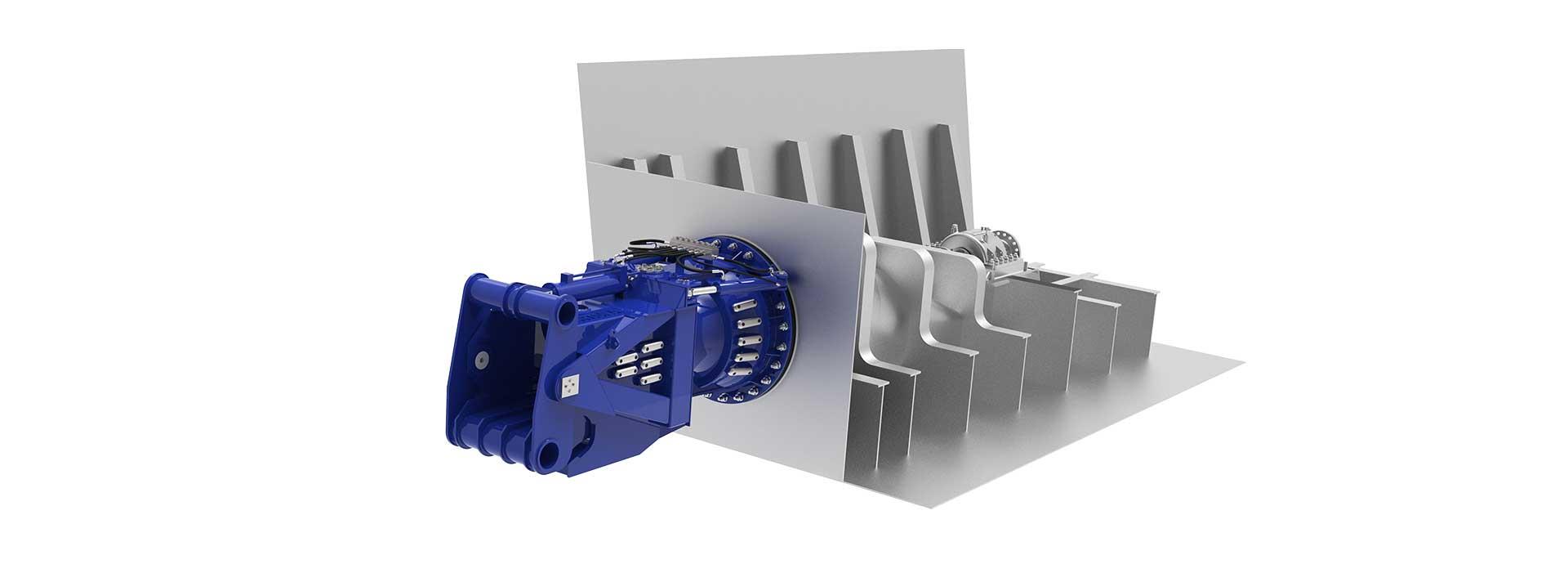

Wärtsilä’s waterjet portfolio consists of two types: midsize and modular waterjets, which have a range of approximately 500 kW up to 33,000 kW. The main difference between the two is in the way they are delivered to the customer.

“The strength of the midsize is the shorter delivery time and the use of aluminium components built together on a skid. The modular waterjet, on the other hand, offers a high-level of customisation with a wide variety of options available depending on the vessel type,” says Vedder.

Both the midsize and the modular waterjet have their own unique selling points. For smaller sized vessels, a pre-assembled, plug-and-play waterjet that is mounted on a skid and has a significantly short delivery time, is great. It reduces installation time at the shipyard and therefore can reduce costs.

“The midsize waterjet, including the inlet duct, is completely built in-house at Wärtsilä. However, this way of building limits the size to a smaller range as otherwise, the package would be too big to handle,” explains Vedder. “On the other hand, the modular waterjet is more customisable and can be used for many special one-off projects.”

Wärtsilä is now concentrating on developing the midsize and modular waterjets even further.

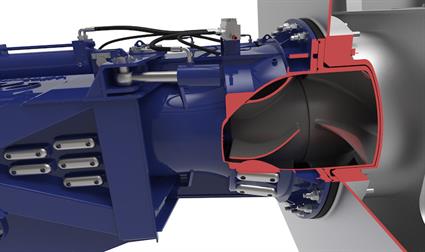

Brand-new series

Vedder is working with a redesign of Wärtsilä’s Modular waterjets at the moment. The last time the modular waterjet design had a big revamp was in July 2006, when Wärtsilä introduced the LJX range of waterjets. The new waterjet with an axial pump design comes with a 25% reduction in mounting flange diameter, 10% overall weight reduction and a 35% increase in cavitation margin compared to its predecessor, the LJ type with a mixed flow pump design. The redesign will see the LJX-series evolve into the new WXJ-series.

This new modular WXJ waterjet series will feature an improved axial pump design, which will boost performance with an increased thrust of as much as 3%, while the improved cavitation margins will help reduce environmental impact by lowering noise levels.

“This is very much in line with Wärtsilä’s ‘Smart Marine’ vision which is to lead the maritime industry into a new era of ultra-high efficiency, improved safety and reduced environmental impact,” says Vedder.

The new axial pump structure is already a factor that sets Wärtsilä apart from its competitors in the market for larger size waterjets. Compared with the mixed flow structure, the axial pump needs much less space in the vessel’s transom, and increases cavitation margins for better operational flexibility. Furthermore, there is a significant weight difference that tilts the argument in favour of the axial pump rather than the mixed-flow pump.

The new WXJ pump has been tested extensively, both with computational fluid dynamic (CFD) simulations and with model testing. With this successful upgrade, Wärtsilä is now in a position to deliver waterjets worldwide, including to promising markets like China and the other Asian countries.

A class apart

Vedder also lists other advantages that set Wärtsilä waterjets apart from other products in the market. For instance, all Wärtsilä waterjets have an inboard mounted thrust bearing. Technically, this means that the thrust bearing is not within the water flow of the jet, which means there is never a risk of oil leaking into the water.

“Usually the equipment that makes the jets steer and reverse is located outside the vessel, and is being exposed to the sea water,” explains Vedder. “This means it can sometimes be difficult to maintain and repair. But we have the option to install them inside the vessel, which allows early and easy detection of possible oil leakage.”

Meanwhile, the Wärtsilä waterjets team is continuously working on innovative solutions that will open new possibilities for Wärtsilä’s new and existing customers.

“The team has listed a number of revolutionary ideas. I am looking forward to the future with enthusiasm,” says Vedder.