One stop shop for engine and turbocharger maintenance in Americas

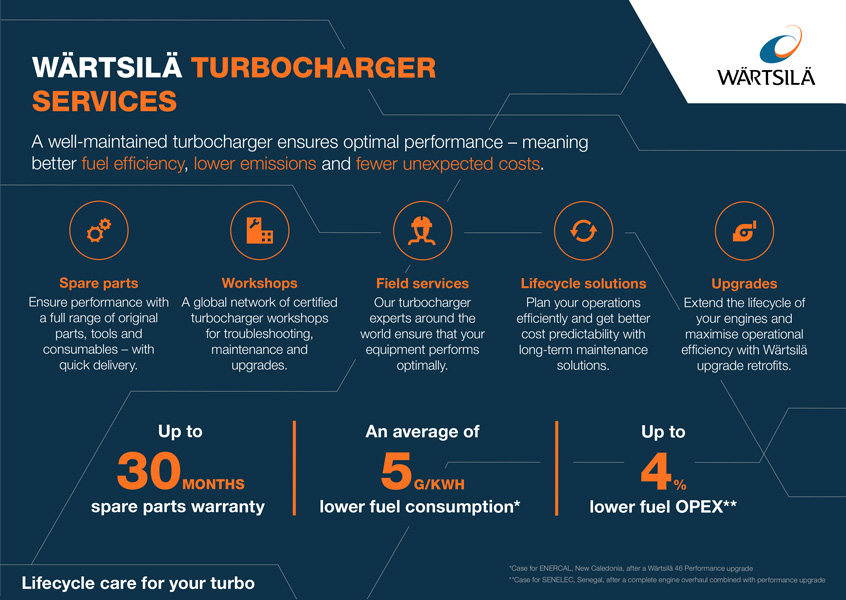

Keeping your turbochargers in prime condition and up to date is essential for the overall performance of your engines. A well maintained turbocharger ensures maximum fuel efficiency and prevents unexpected operational costs.

Turbocharger maintenance, combined with engine maintenance or separately, can be provided as a long term maintenance solution, extending the lifetime of all types of equipment for your installations. Learn more about Wärtsilä Turbocharger services.

Video – Boost your engine with a Wärtsilä Performance upgrade

Wärtsilä at your service in Americas

In Americas and Canada, there is an installed base of over 2600 turbochargers. Today, a total of over 1200 operating land based engines in the area trust Wärtsilä’s high quality maintenance.

When it comes to keeping the turbochargers running efficiently and preventing unexpected failures, Wärtsilä stands at your service. With over 140 dedicated professionals in the area, we are ready to serve you in the best possible way.

Turbocharger maintenance is essential for the overall performance of the engine.

As an engine manufacturer Wärtsilä has extensive experience and expertise in turbocharging technology and is the only true global service provider in the market licensed to service ABB, Napier and KBB turbochargers.

A wide range of genuine spare parts for the complete installation and auxiliary systems are available thanks to our worldwide strategic agreements. Regularly auditing our supply chain ensures that our customers receive high quality, cost-efficiently, on time.

Wärtsilä’s power plant installed base in Americas currently produces approximately 10.6 GW in 37 countries.

Source: QlikView, Wärtsilä’s internal database

Case Senelec: Turbocharger upgrade brings economy into operations

Turbocharger upgrades on Wärtsilä 46 engines for Senelec’s Kahone II plant significantly reduced fuel consumption and exhaust temperatures.

The extreme ambient conditions encountered in Senegal pose particular challenges for power generation equipment. Senelec, the Senegalese national electricity company, contracted Wärtsilä and ABB Turbocharging to carry out a series of turbocharger upgrades on some of the diesel generators that are so critical to the nation’s power supply.

Like many other utilities, Senelec depends heavily on the high reliability and performance of its Wärtsilä 18V46 engines fitted with ABB TPL 77 turbochargers. Because of the extreme heat, the engines are often derated, that is, operated at less than their full capacity. Such a situation may be improved by a turbocharger upgrade.

The head of production at Senelec was initially unsure about the benefits of a turbocharger upgrade: “I was dubious at the beginning about the real gains a turbocharger upgrade could bring to our engines. My colleagues at Senelec, as well as myself, showed some hesitation and asked ABB and Wärtsilä to give some performance guarantees.”

He was very pleased with the outcome: “After the upgrade, the exhaust temperature was down by 40 to 45 K and we had a reduction of the specific fuel oil consumption of about two percent. We were very satisfied.” he continued, “not only did we get the temperature and fuel reduction but it now seems we can also get an extra 500 kW from each of our Wärtsilä 18V46 engines.”

Quantified benefits for the customer

- Fuel savings of 2 percent (800,000 Euro annually, with 4 engines)

- Power output increase of 2 MW (330,000 Euro annually)

- 40 to 45 K reduction in exhaust gas temperatures resulting in higher reliability

- A happy customer, ready to do the next upgrade of this kind.

Achievements

The ability to get an extra 500 kW out of each engine for six hours a day for six months of the year brings about revenues of roughly 330,000 Euro for additionally sold power (assuming an energy sales price of 0.18 Euro/kWh).

Reduced fuel consumption contributes about 800,000 Euro of savings per year (at a fuel price of 461 Euro/t in May 2019), so that the upgrade investment pays back in less than a year for Senelec.