Australia stands at the forefront of the global energy transition, with impressive progress in adopting renewable energy from wind and solar. But as renewable penetration increases, so does the challenge of intermittency. For utilities and independent power producers (IPPs), the priority is no longer just about expanding renewable capacity. It’s about ensuring that power generation remains both reliable and responsive to constantly changing demand.

Wärtsilä’s flexible engine power plants are built to meet this need. Capable of starting within minutes and maintaining high efficiency across a wide range of loads, they help utilities and IPPs stabilise the grid, manage peak demand, and respond quickly to renewable fluctuations. At the same time, they create new revenue opportunities by enabling fast, accurate responses in Australia’s dynamic energy markets.

Flexibility that balances renewable intermittency

As more renewables enter the grid, flexibility becomes essential. Wärtsilä’s engine power plants are designed to provide rapid, reliable support by responding instantly to changes in supply and demand.

High efficiency

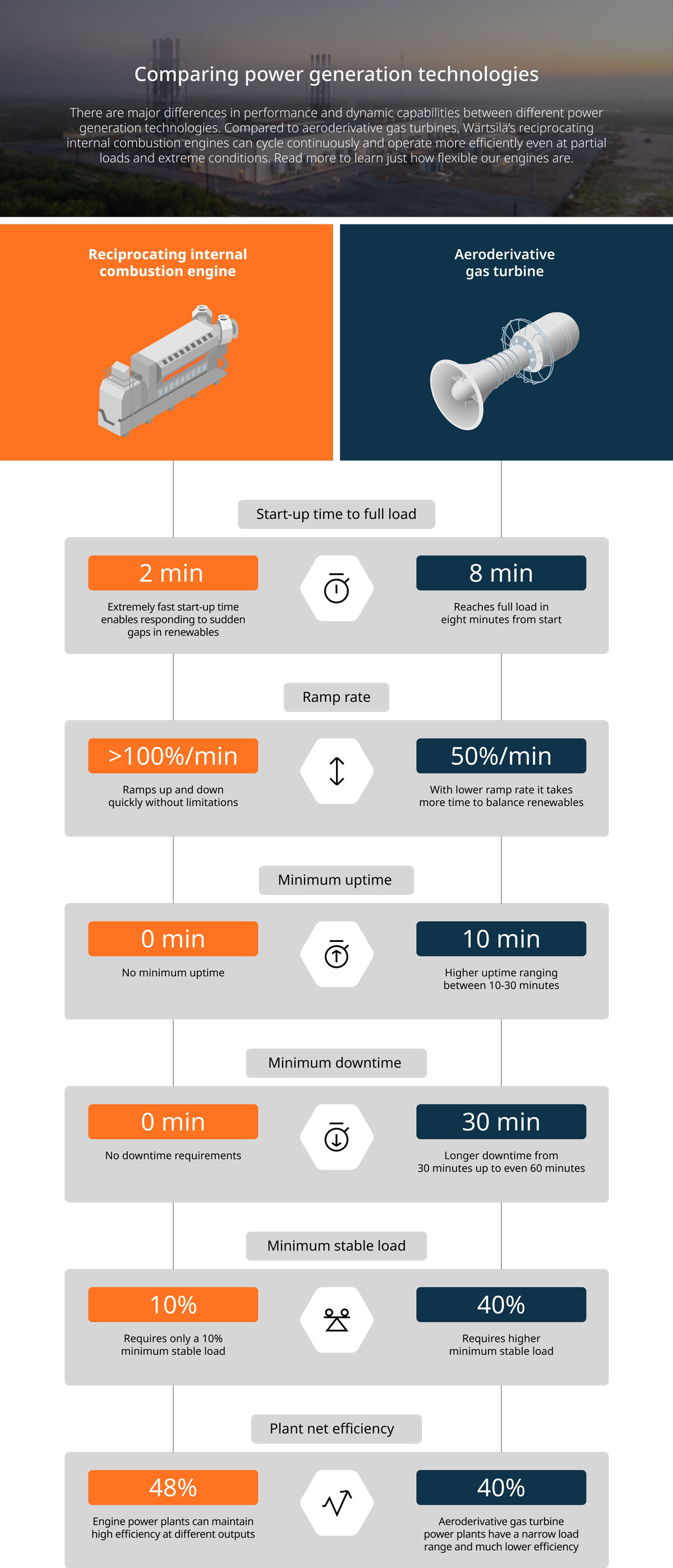

Unlike traditional gas turbines, these engines can reach full load in just minutes and maintain high efficiency, even when operating at only 10% capacity. With up to 48% net efficiency across a wide range of loads, they consume significantly less fuel, up to 28% less than turbine alternatives.

Modularity

Their modular design allows operators to start only the number of engines needed at any given time. If one engine goes offline, the others continue running independently, ensuring uninterrupted power. This level of redundancy makes them ideal for balancing both baseload and peaking needs.

Stability

To further strengthen grid stability, Wärtsilä engines can be equipped with a synchronous condenser feature. The synchronous condensers stabilise grid frequency and voltage, and support faster recovery during power grid faults such as short-circuits, helping maintain system stability as more renewables enter the grid.

Resilience

Built for extreme conditions, Wärtsilä engines perform reliably even in 50-degree Celsius heat. With negligible water consumption and the ability to operate on low fuel gas pressure, these features add another layer of operational resilience.

Flexibility that improves profitability

In Australia's National Electricity Market (NEM) and South West Interconnected System (SWIS), where renewable energy penetration is high, flexibility has become a critical financial asset. Wärtsilä's engine power plants are engineered to ramp up and down rapidly with minimal wear, avoiding the costly cycle limits and extensive overhauls often associated with traditional gas turbines.

The shift to five-minute settlement intervals has only increased the need for flexible power generation. Wärtsilä's engines enable utilities and IPPs to react quickly to price spikes and system needs, allowing them to monetise their flexible capacity effectively. By participating in ancillary service markets and providing rapid dispatchable power, engine-based plants shift from being cost centres to sources of revenue with multiple income streams.

Flexibility that future-proofs your investment

Wärtsilä’s engine power plants are designed for fuel flexibility, capable of operating on a wide range of gaseous and liquid fuels, including 100% synthetic, carbon-neutral methane and up to 25% vol. hydrogen blend with natural gas. Our dual-fuel engines can switch seamlessly between fuels – without reducing load or compromising power plant availability.

To support the transition away from fossil fuels, we’ve introduced the world’s first large-scale engine platform designed to operate on 100% hydrogen. Our technology also enables fuel conversions, allowing engines to run entirely on sustainable fuels as they become available.

This makes today’s investments in engine technology future-proof to tomorrow’s energy landscape without the risk of them becoming stranded assets as the grid moves toward full decarbonisation.

Introducing Wärtsilä 46TS: best-in-class efficiency and power output

The Wärtsilä 46TS is a proven technology and our most advanced and flexible engine platform, purpose-built to support both renewable integration as well as deliver cost-effective baseload power.

Key benefits of the Wärtsilä 46TS

Power

High mechanical output (23.4 MW/unit) means fewer engines are needed to meet demand, simplifying plant design and reducing overall capital cost.

Efficiency and performance

World-class efficiency (51.3%) saves fuel and reduces emissions.

Excellent performance in extreme ambient conditions, with no derating required in temperatures ranging from -55°C to +55°C.

Flexibility

Rapid response to fluctuations with fast ramp-up time (2 minutes).

No minimum up or downtime requirements.

Engines vs. aeroderivative gas turbines: what are the key differences?

Reciprocating internal combustion engines have been proven to start and stop quickly, adjust power rapidly, and operate efficiently at various loads when compared to aeroderivative gas turbines (aeros). In other words, engines are more flexible.

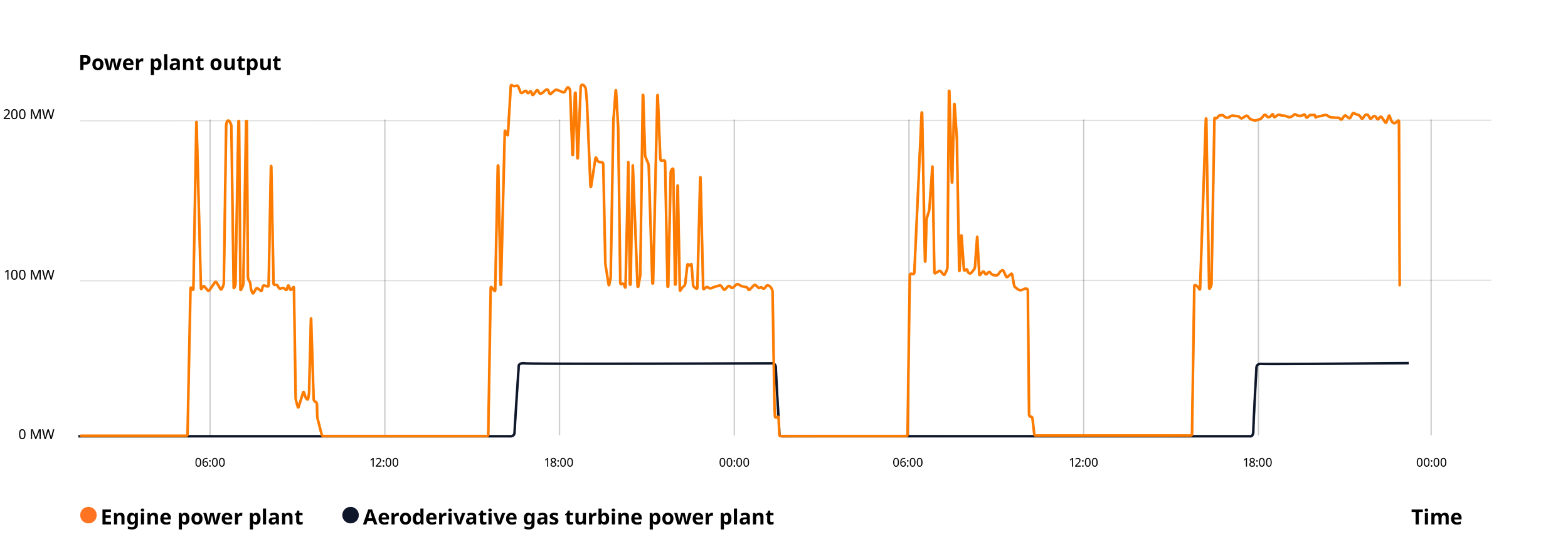

We gathered real-world data from the South Australia’s National Electricity Market to show how two power generation technologies, engines and aeros, behave as a part of the power system.

In this animation video, we demonstrate the exceptional flexibility that engine power plants provide in balancing renewables. There is now clear evidence that engines are dispatched much more frequently and earlier than aeros. We can also see how the engines provide continuous balancing of renewables on a minute-by-minute basis.

Proven results in Australia and worldwide

Wärtsilä has delivered over 900 MW of power generation capacity across Australia and Oceania, supporting the region’s transition toward a more flexible, decarbonised energy future. With offices in Sydney, Perth, and Port Moresby, and fully equipped workshop facilities in Sydney, we provide end-to-end solutions and lifecycle support to both energy and marine customers across the region.

Barker Inlet Power Station (BIPS)

Torrens Island, South Australia

In partnership with AGL Energy Limited, Wärtsilä supplied 12 x 50DF dual-fuel engines for the 211 MW Barker Inlet Power Station. Commissioned in 2019, the plant was built for rapid-start operation and high efficiency, playing a crucial role in balancing renewables within the National Electricity Market.

Zenith Energy Operations

Kalgoorlie, Western Australia

Wärtsilä will supply the engines, controls, and auxiliary equipment for a new 120 MW power plant in Kalgoorlie, Western Australia. The contract was placed by Australian Independent Power Producer (IPP) Zenith Energy Operations. The plant is expanding the power supply of one of Australia’s largest gold mines, Kalgoorlie Consolidated Gold Mines (KCGM). The power plant's synchronous condenser feature strengthens the grid during times with high inputs of renewables, improving the grid’s voltage and frequency stability, and short-circuit capacity.

Lower Colorado River Authority (LCRA)

Austin, Texas

Wärtsilä was selected by the Lower Colorado River Authority (LCRA) to deliver an additional ten Wärtsilä 50SG gas engines, following a previous 190 MW order. With this second phase, LCRA is doubling its engine-based capacity to enhance grid flexibility and provide fast-start support during peak demand.

Mexico's Federal Electricity Commission

Mexicali, Baja California & San Luis Río Colorado, Sonora

In partnership with Mexico’s Federal Electricity Commission (CFE), Wärtsilä delivered two large power plants – the 400 MW Mexicali Oriente plant and 200 MW Altar plant – to strengthen electricity supply in Baja California. Despite extreme summer temperatures reaching 50°C and global supply chain challenges, Wärtsilä was able to complete both projects in well under two years from contract signing.

Centrica

Brigg & Peterborough, UK

Centrica partnered with Wärtsilä to deliver two 50 MW flexible gas power plants to address intermittency from renewables and provide balancing capacity with under two-minute startup time, supporting the UK’s transition to a decarbonised energy system.

Safe, reliable performance with Wärtsilä Lifecycle services

At Wärtsilä, our commitment to customers extends well beyond project delivery. We provide long-term lifecycle services that combine decades of global power generation experience with the latest digital technologies like advanced analytics, artificial intelligence and machine learning. With Wärtsilä as your lifecycle services partner, you can ensure safe, reliable and efficient operations throughout the lifetime of your power plant.

Our remote support solutions, including real-time monitoring and 24/7 remote support through Wärtsilä Expertise Centres, help you to cut operating costs through data and infrastructure optimisation, preventing problems before they occur.

In Australia, Wärtsilä has been serving customers with local service capability since 1989, when Wärtsilä Australia was first established. Today, our 1,800 m² fully equipped workshop in Sydney provides component overhauls and services for Wärtsilä products. Supported by a diverse and experienced field service and workshop team, we offer 24/7 local support to ensure your power plant runs safely, reliably and efficiently throughout its entire lifecycle.

We offer service agreements tailored to your needs:

Wärtsilä Optimised maintenance

Ensure safe and reliable operations:

- Power plant maintenance by Wärtsilä with predictable maintenance costs

- Services and support from Wärtsilä Expertise Centres

Wärtsilä Guaranteed asset performance

Ensure power plant performance:

- Power plant maintenance by Wärtsilä with performance guarantees.

- Services and support from Wärtsilä Expertise Centres

Wärtsilä Operation and maintenance

Protect your investment:

- Power plant operation & maintenance by Wärtsilä with performance guarantees.

Let’s talk

Wärtsilä is ready to support Australia in building a more flexible, cost-effective, and future-proof power system. If you'd like to discuss how our engine solutions could fit into your plans, get in touch with our local experts today!

Paul George

Business Development Manager, Australia & Pacific

Email: paul.george@wartsila.com

Mobile: +61 451 690 762

Javier Savolainen

Manager, Market Development

Email: javier.savolainen@wartsila.com

Mobile: +65 80 771 391

Partha Paul

Business Development Manager, Australia & Pacific

Email: partha.paul@wartsila.com

Mobile: +61 415 254 582