Controllable pitch propeller systems

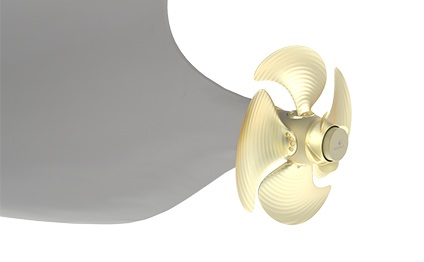

Controllable Pitch Propellers (CPPs) can be used to run the ship forward and backward without changing the direction of the engine’s rotation. Wärtsilä’s CPP system includes several components.

CPP system components

Wärtsilä’s CPP system is a customised combination of

- A hub

- Propeller blades

- Shafting

- Hydraulics

- Control system

- Any accessories to meet a customer’s specific needs

The customised and optimised shaft line configuration meets the vessel requirements, allowing the right fit for the project – and excellent operational performance for the vessel as well.

Wärtsilä’s hydrodynamic experts will tailor the propeller for each application to achieve the optimum balance between fuel consumption and comfort levels as set by the customer.

Who would benefit from a CPP system?

Wärtsilä’s CPP system is an ideal choice for vessels that have frequent sailing routes involving several operating conditions.

Your vessel may benefit from Wärtsilä’s CPP system if:

- she has to use high power both in bollard pull and free-sailing conditions

- she has demanding operational requirements such as Dynamic Positioning (DP) or sailing in icy conditions

- her propulsion plant contains multiple engines and/or has a hybrid power arrangement

- she makes frequent port calls

- she faces a wide variety of weather conditions during voyages

Applications of a CPP system

The CPP system can adjust its pitch and meet the power requirements even when operating at constant speeds.

Vessel types that will benefit from this include:

- Ferries

- Dredger

- Trawlers

- Ice-class merchant vessels

Wärtsilä’s CPP system is ideal for mechanical propulsion with medium-speed or low-speed combustion engines. With integrated gearbox and Power Take Off/In, this system transforms into an extremely efficient, flexible hybrid propulsion system that can deliver:

- A power boost mode

- Emergency propulsion power

Ship engines can communicate with a smart propulsion control system to optimise the efficiency of the engine and propeller according to actual operating conditions. Using fuel-optimised propeller pitch and engine speeds will save fuel during transit. Operation is safe and very efficient.

Key benefits of Wärtsilä’s CPP system

Wärtsilä’s CPP systems are efficient, deliver excellent performance, and minimise the noise and vibration.

- Get what you need. The system can be tailored to the customer's requirements, even matching the requirements for dynamic positioning (DP) and ice class applications.

- Comfortable. A customised propeller design reduces noise and vibration.

- Reduces risks. Extremely reliable thanks to design based on decades long experience.

- Saves the environment. Wärtsilä’s CPP system can comply with the EPA Vessel Permit 2013 requirement. It can be delivered with environmentally acceptable lubricants (EALs). The special stern tube system can ensure zero pollution.

- Saves fuel. The system can be optimised for best overall efficiency because the OPTI Design TM methodology considers the full interaction between the propeller system and vessel hull.

- Saves you from hassles. The system is easy to install and maintain.

- Easy to use. Wärtsilä’s ProTouch system makes it easy to control the ship’s propulsors. Control is as easy whether there is a single propulsor or several.

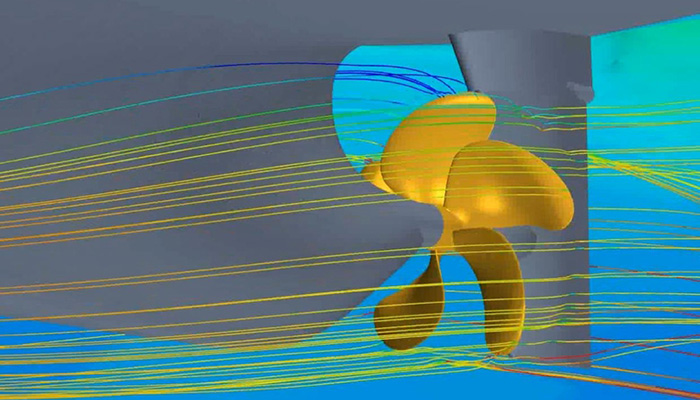

OPTI Design

Wärtsilä’s OPTI Design methodology combines computational fluid dynamics with special expertise. The process delivers great results, and your propeller, engine, and hull can be a perfect match when they work together.

Propeller feathering

Feathering the blades of the propellers will save fuel for multi-functional vessels when they operate regularly with one or two propellers out of use.

Positioning the propeller blades for feathering reduces resistance and saves fuel compared to a trailing or blocked propeller.

Ahead propulsion position

Feathering position

Common applications for propeller feathering

Double ended ferries. With propellers at both the bow and stern of the ferry, the foremost propeller is not in operation during transit.

Twin screw vessels. Twin screw container or cargo/RoRo vessels operating with one propeller at low speed for longer periods, for example when the sailing route involves both high and low speed operation.

What’s more, propeller feathering on a twin-screw vessel makes it possible to perform maintenance on one of the shaft lines without stopping operations.

Vessels with a booster propulsor. Vessels with a centre propeller and wing thrusters can operate on thrusters alone whenever lower sailing speed is required.

Vessels with alternative propulsion. Sailing cruise vessels or sailing yachts use wind propulsion and propeller feathering minimises resistance when the mechanical propulsion system is not in use.

“Around 20,000 vessels in the world are working with controllable pitch propellers (CPP) and every 4th vessel has a Wärtsilä CPP.

CPP system: technical information

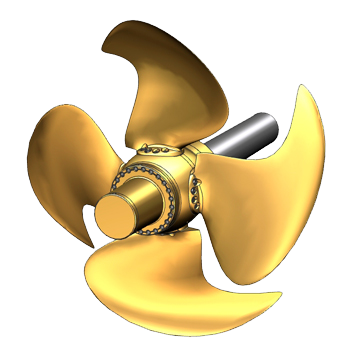

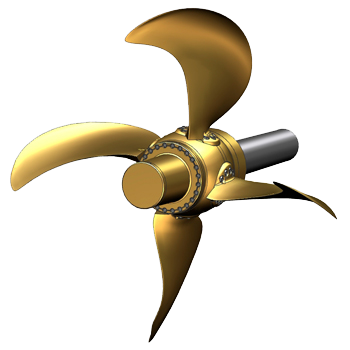

Power range starting from 1000 kW, no upper limit

- 4- or 5-bladed propellers starting at a diameter of 1200 mm

- Bronze or stainless steel propellers

- Various hub types, depending on the application

- Compliant with all ice classes.

Wärtsilä’s CPP systems are available in three configurations:

- A reduction gear box and with the oil distribution unit connected to the forward end of the gear box.

- A reduction gear box that produces the hydraulic pressure for pitch actuations.

- Direct drive without a gear box.

Wärtsilä offers several choices of controllable pitch hub principles (up to 60 MW): we will find the best match for your needs.

- Hub type D is the right solution for light and moderately loaded propellers.

- Hub type G is selected for vessels requiring high power or heavily loaded propeller.

These two hub types meet the needs of vessels that require controllable pitch propellers.

Customer stories and references

Discover the benefits others have already gained from Wärtsilä’s controllable pitch propeller systems.

Case: P&O Ferries prefers Wärtsilä’s CPP systems

P&O Ferries is a prominent operator of crossings between Ireland, Great Britain and the European continent. Their core points are safety, reliability, efficiency and the environmental impact. One of the ways to achieve those goals was to fit the Pride of Canterbury ferry and her sister ships with controllable pitch propellers (CPP).

CPP systems provide excellent performance and manoeuvrability and are perfect for ships with frequent sailing routes that can involve multiple operating conditions and frequent port calls – just like Pride of Canterbury and her sister ships.

Case: Lady Hanneke cargo ship

The narrow straits, scattered landmasses and ice in the Baltic Sea and the surrounding Arctic regions make for treacherous conditions for ships. This makes shipping in the region challenging, and ships must be designed to special ice-class standards.

The Lady Hanneke is one such ship. This ice-class 1A vessel is operated by Netherlands-based shipping company Wijnne Barends.

Low greenhouse gas emissions are a crucial element for Wijnne Barends because of the eco-sensitive nature of the Baltic Sea. It can be a challenge to balance between low emissions and sailing speeds. Wärtsilä’s Controllable Pitch Propeller (CPP) proved to be a big part of the integrated solution to meet these challenges.

The result of the integrated solution has been a huge success, and Lady Hanneke has seen 4% fuel savings achieved compared to other similarly designed vessels.

What about services?

To meet your evolving needs, Wärtsilä’s services for CPP systems can support you regardless of the location of your assets. Keep your installation running smoothly and achieve significant OPEX savings. Take a look at the services available for CPP systems.

Support is available for scheduled inspections and maintenance, as well as for unscheduled repair needs. With this kind of support, you will be able to focus on your core business.

Related products and services

The Wärtsilä EcoControl is a smart propulsion control system for marine vessels. It will automatically use the most efficient setpoint between propeller pitch and engine RPM, adjusting the parameters in real time. As a result, the vessel’s efficiency can increase by up to 7%. This saves fuel.

Handpicked press releases

Interesting insights on propulsion

Discover these insightful articles – they will build your knowledge of propulsion solutions.

Reach out to Wärtsilä to discover how our controllable pitch propellers, the CPP system and related solutions can enhance your fleet’s performance.