Wärtsilä Modular Waterjets - Jet powered efficiency and reliability

The Wärtsilä WXJ modular waterjets represent the state-of-the-art in this field, delivering outstanding benefits and performance and offering a high-level of customisation with a wide variety of options available depending on the vessel type.

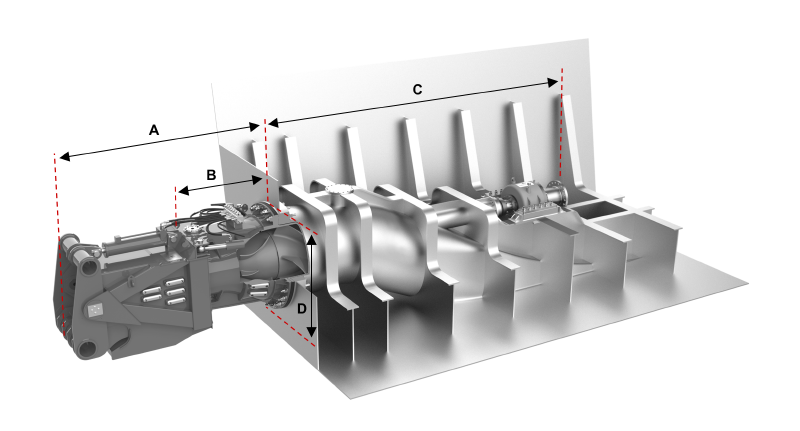

The Wärtsilä WXJ series of modular waterjets features an improved axial pump design, which boosts performance with an increased thrust of as much as 3 percent, while the improved cavitation margins help reduce the environmental impact by lowering noise levels. This axial pump design comes with a 25% reduction in mounting flange diameter, 10% overall weight reduction and a 35% increase in cavitation margin compared to its predecessor, the “LJ type” with a mixed flow pump design, while the small transom interface dimensions, and best in class weight are unchanged.

Applications

The characteristics of a waterjet make it a good propulsor for numerous applications.

- High speed vessels; waterjets have better propulsion efficiency at ship speeds over 25-30 knots.

- Shallow draft vessels; the integrated steering function provides benefits for rescue vessels, inshore passenger ferries, landing crafts & special work boats.

- High power density; the pressure built-up in the waterjet inlet allows small dimensions.

- Maneuverability; waterjets have integrated steering and reversing with quick response times.

Examples of such applications include:

- Fast ferries

- Littoral combat ships

- Fast patrol boats

- Rescue vessels

- Fast yachts

- Fast supply vessels and workboats

- Landing craft

Key benefits

Wärtsilä axial waterjets are single stage, compact, high performance systems that combine mixed flow properties with an axial construction. This results in much less space being needed on the vessel’s transom, and greatly increased waterjet cavitation margins for optimum vessel operational flexibility. For naval architects, the axial jet technology creates the possibility to apply a larger power density onto narrower hulls in order to achieve top vessel performance.

- Lowest size to weight ratio in the market

- Axial pump design means less space on the transom

- Worldwide availability, including China, Japan, Korea, etc.

- Inboard mounted thrust bearing block, for increased life and easy maintenance

- Optional inboard hydraulics

- High-performance components in Duplex stainless steel to prevent wear and corrosion

- Impeller tip clearance guaranteed due to axial shape and no risk of impeller housing collisions.

- Customisable to meet your needs

- Fully integrated solutions available

Technical info

| Weight & dimensions table | ||||||

|---|---|---|---|---|---|---|

| Size | Outboard length SR (mm) |

Outboard length B (mm) |

Inboard length (mm) |

Transom flange (mm) |

Mass steerable (kg) |

Mass booster (kg) |

| 510 | 1500 | 610 | 2510 | 655 | 750 | 550 |

| 570 | 1650 | 650 | 2790 | 730 | 1050 | 750 |

| 640 | 1860 | 730 | 3040 | 820 | 1450 | 1150 |

| 720 | 2040 | 790 | 3360 | 920 | 2050 | 1450 |

| 810 | 2310 | 900 | 3670 | 1035 | 2850 | 1950 |

| 910 | 2560 | 980 | 4110 | 1165 | 4150 | 2550 |

| 1000 | 2800 | 1060 | 4420 | 1280 | 5150 | 3450 |

| 1100 | 3040 | 1130 | 4770 | 1405 | 6700 | 4300 |

| 1200 | 3320 | 1230 | 5230 | 1535 | 8600 | 5750 |

| 1300 | 3580 | 1330 | 5590 | 1665 | 10950 | 7100 |

| 1400 | 3870 | 1450 | 5940 | 1790 | 13150 | 8200 |

| 1500 | 4120 | 1520 | 6430 | 1920 | 15900 | 10100 |

| 1620 | 4470 | 1650 | 6860 | 2075 | 20400 | 12650 |

| 1720 | 4770 | 1780 | 7270 | 2200 | 21500 | 15300 |

| 1880 | 5200 | 1930 | 7840 | 2405 | 31450 | 18900 |

| 2020 | 5550 | 2140 | 8320 | 2585 | 36150 | 23400 |

| 2180 | 6000 | 2300 | 8880 | 2790 | 43900 | 29100 |

| 2350 | 6440 | 2470 | 9460 | 3005 | 53000 | 34000 |

Downloads & links

Waterjet size selection

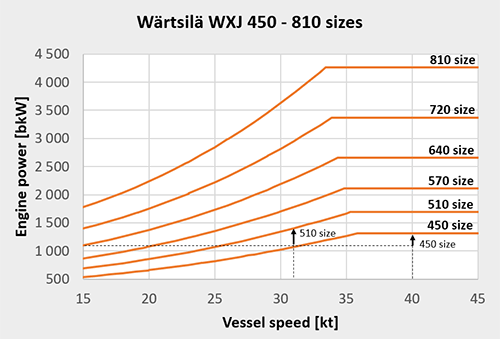

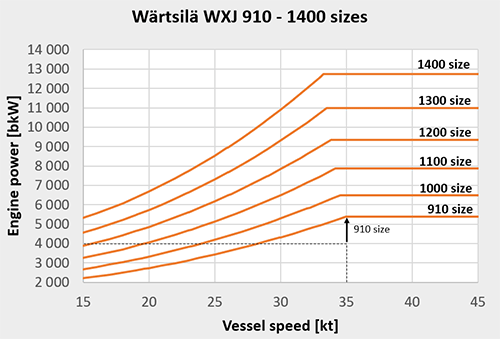

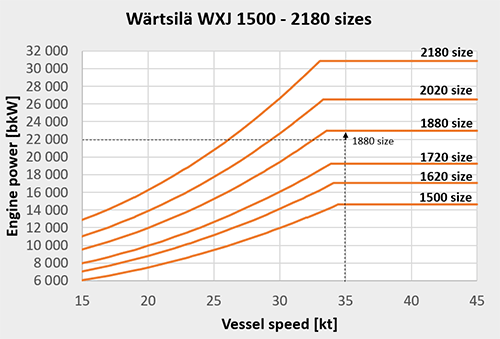

The selection graphs indicate the jet size required based on the relation between the engine power and the design speed of the vessel. For instance a ship with four 1250 kW engines and a corresponding vessel speed of 33 knots will need four 510 size waterjets. A ship with a design speed of 40 knots at 1250 kW power can use 450 size waterjets. The correct jet size is thus indicated by the line above the intersection of the power and the corresponding vessel speed (see examples in the graphs below).

We are available from the earliest design stages of the vessel to work with you on an optimised propulsion system. Please contact us for an optimised jet selection based on specific vessel design parameters, operating profile or for details of waterjets above 50 knots or 30 000 kW. DXF/DWG format general arrangement drawings of the most often used sizes are available.

Additional design information can be found in the “Waterjets Product guide”, which can be pre-ordered on this page.

Customer stories

Press releases

Articles on publications

29 May 2020 by Riviera News

Faster, lighter, smoother – the advantages of waterjets

19 Feb 2020 by Selwyn Parker

Wärtsilä keeps Incat in the fast lane

28 Feb 2018 by David W.Smith