Wärtsilä transverse/tunnel thrusters WTT

Transverse thrusters, also known as tunnel thrusters, bow thrusters or stern thrusters, provide a side force, or transverse thrust, to support mooring operations or station keeping.

Wärtsilä WTTs have compact dimensions, yet they deliver high thrust. They are available in a range from 400 kW to 5500 kW and are an excellent choice for ships such as:

- merchant vessels

- cruise vessels

- offshore support vessels

- offshore construction vessels.

In auxiliary applications, transverse thrusters support the mooring or harbour operations of merchant cargo vessels.

When applied in Dynamic Positioning systems, transverse thrusters extend the DP capability of, for example, offshore supply vessels.

Key benefits

- Superior hydrodynamic performance for high thrust - diameter ratio

- Robust, reliable and maintenance friendly design

- Easy installation; high level of integration

- Maintenance friendly design

- Wärtsilä ProTouch controls with ergonomic levers and intuitive touch screen displays or push-button panels

Application

- Wärtsilä transverse thrusters are available in a range from 400 kW to 5500 kW for applications in numerous types of ships, including merchant vessels, cruise vessels, offshore support vessels, and offshore construction vessels.

- Transverse thrusters, also known as bow thrusters, stern thrusters or tunnel thrusters, provide a side force, or transverse thrust, to support mooring operations or station keeping.

- Transverse thrusters are available for auxiliary or AUX usage, which is mostly applicable with merchant vessels to support harbour manoeuvring and mooring operations. Where the transverse thruster is part of a dynamic positioning (DP) system, the rating for DP use applies.

Merchant

- Cost per kW - 15% reduced cost (CAPEX) per kW*

- Environmental compliance - Compatibility with environmentally acceptable lubricants (EAL) - Ensures compliance with environmental regulations such as US EPA VGP2013 and DNV CLEAN DESIGN

- Smaller footprint - Integrated hydraulics and fine filtration ensures longer lifetime for gear, bearings and other rotating components

- User centric interface - ProTouch control system - bus connections for simplified installation and integration with other equipment control, monitoring and alarm systems

- Global support - Service and delivery available when and where you need it

- Reliability - Robust design for reliable operations in demanding environments and low operational cost

- Experience - over 1,250 Wärtsilä Transverse Thrusters delivered or on order in the Merchant segment, of a total of 3,250 units

- Flexible Options – WTT are available in CPP and FPP giving you the option to select the right system to meet your needs.

*Compared to a standard Wärtsilä Transverse Thruster with the same propeller diameter. The improvement may vary depending on configuration, fuel, vessel and currency.

Options

- Controllable or fixed pitch propeller upto WTT-40 type; CP propeller for WTT-45 and CT3500 types

- Manoeuvring (AUX) or Dynamic Positioning (DP) application

- Redundant pumps and/or lubrication filters

- Compatible with environmentally acceptable lubricant (EAL) for EPA VGP 2013 compliance or CLEAN notation compliance

- Face type seal or Air barrier seal for WTT-21 and up

- Tailor-made tunnel with tunnel ends cut according to hull form and additional circular or longitudinal stiffeners

- L-drive with intermediate shaft and separate E-motor foundation

- De-mountable, low noise, horizontal drive variants

- Package with electric motor and starter

Technical info

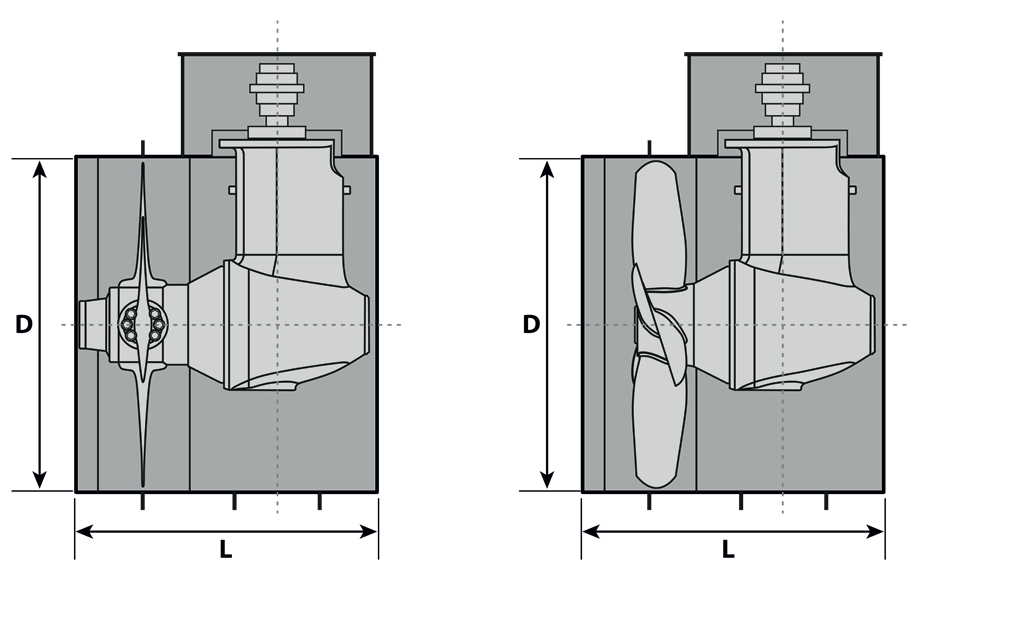

Range and dimensions

| Type | Electrical Frequency (Hz) | Input Speed (rpm) | Maximum Power 1 | Propeller Diameter (D) (mm) | Length (L) (mm) | Weight 2 (kg) | |

| Manoeuvring AUX/Merchant (kW) | Dynamic Positiong DP (kW) | ||||||

| CT/FT125 H | 60 50 | 1780 1480 | 610 510 | 600 500 | 1250 | 1550 | 2800 |

| CT/FT150 H | 60 50 | 1780 1480 | 880 735 | 780 650 | 1500 | 1800 | 4150 |

| WTT-11 | 60 50 | 1180 980 | 1100 1100 | 1000 1000 | 1750 | 1970 | 5750 |

| WTT-14 | 60 50 | 1180 980 | 1450 1450 | 1300 1300 | 2000 | 2195 | 8000 |

| WTT-16 | 60 50 | 1180 980 | 1650 1650 | 1490 1475 | 2200 | 2115 | 10100 |

| WTT-21 | 60 50 | 1180 980 | 2100 2200 | 1825 1825 | 2400 | 2275 | 12000 |

| WTT-24 | 60 50 | 880 980 | 2600 2600 | 2150 2150 | 2600 | 2390 | 13900 |

| WTT-28 | 60 50 | 880 735 | 3000 2800 | 2400 2400 | 2800 | 2970 | 20200 |

| WTT-32 | 60 50 | 710 735 | 3300 3300 | 2800 2800 | 3000 | 3285 | 25400 |

| WTT-36 | 60 50 | 710 735 | 3600 3600 | 3200 3200 | 3200/3300 | 3350 | 29400/29700 |

| WTT-40 | 60 50 | 710 735 | 4000 4000 | 3600 3600 | 3400 | 3520 | 32800 |

| WTT-45 | 60 50 | 710 735 | 4800 4800 | 4050 4050 | 3600 | 3800 | 40400 |

| CT3500 | 60 50 | 590 590 | 5500 5500 | 5000 5000 | 4000 | 4300 | 63700 |

2 Version with CP propeller including a standard tunnel with E-motor support., excluding E-motor.

Weights and dimensions

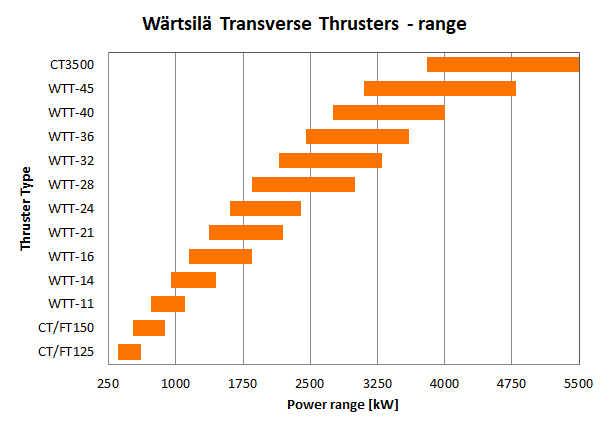

Power range

Press releases

Wärtsilä hybrid propulsion solution to optimise efficiency and enable zero emissions for four new Dutch vessels

Wärtsilä and Elomatic sign licensing and cooperation agreement on Elogrid™ technology

Six new Sallaum Lines vessels to drive sustainability with Wärtsilä solutions