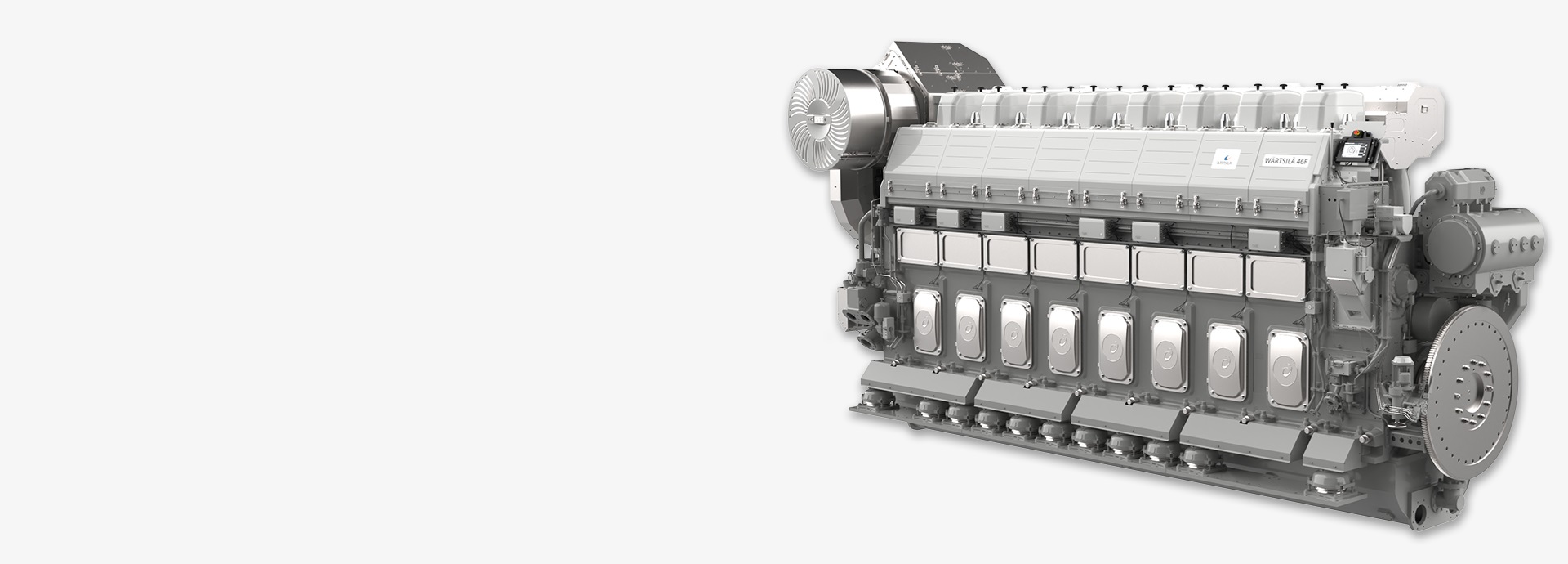

Wärtsilä 46F

Best-in-class fuel economy and outstanding power-to-weight as well as power-to-space ratios

The technologically advanced Wärtsilä 46F can be run on either heavy fuel oil (HFO), marine diesel oil (MDO), or on light diesel when being operated within strict coastal or port emissions areas. This fuel switching can take place smoothly and without power interruption across all engine loads. This flexibility enables the operator to select the fuel according to price, availability, and the need to meet local emissions regulations.

The Wärtsilä 46F engine is fully compliant with the IMO Tier II exhaust emissions regulations set out in Annex VI of the MARPOL 73/78 convention.

Key benefits of the Wärtsilä 46F

- Proven and reliable heavy fuel technology from an industry leader

- Thermal efficiency for complete combustion and minimal exhaust gas emissions

- Fuel economy throughout the entire engine operational range, thanks to an efficient twin-plunger fuel injection system, gives significant cost savings

- Advanced modular design means fewer components, lower inventory costs, less maintenance, and faster crew training

- Extended overhaul intervals provide greater engine availability and reduced operational costs

- Embedded automation system for optimal operating efficiencies

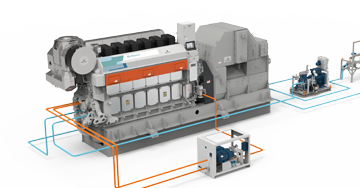

Wärtsilä 46F Product guide and 3D models and drawings

Get technical data and system proposals for designing W46F marine engine installations.

Press releases

Adopting methanol as marine fuel

If you are considering a switch to low-carbon fuel, methanol is an attractive option. Green methanol has the potential to be carbon free, and it meets current and future emissions targets in terms of NOx, SOx and particulates.

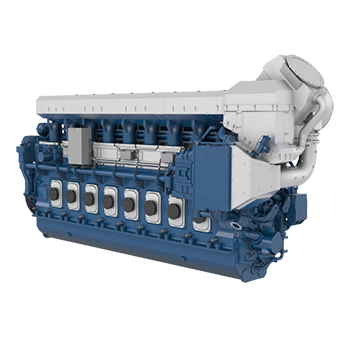

Customer stories

Discover the benefits others have already gained from Wärtsilä 46F engine.