EXHAUST GAS EMISSIONS FROM SHIPS

Exhaust gas emissions increasingly become a more stringent topic of public interest in the context of merchant shipping industry. Exhaust emissions from marine diesel engines comprise nitrogen, oxygen, carbon dioxide (CO2), carbon monoxide (CO), oxides of sulphur (SOx), nitrogen oxides (NOx), hydrocarbons, water vapour and smoke. Oxides of nitrogen and sulphur are of special concern as threats to vegetation, the environment and human health.

NOX emissions

During combustion, most of the nitrogen oxides (NOx) are generated in the high temperature spots by a reaction between the atmospheric nitrogen and oxygen. Nitrogen oxides cause eutrophication, acidification and the formation of ozone in the presence of VOC and sunlight. These NOx emissions can be abated by using primary and/or secondary methods. Primary methods aim at reducing the formation of NOx emissions in the engine using engine design methods, or additionally through water injection or exhaust gas recirculation. For ships requiring the lowest possible NOx emissions, the only viable solution available today is to treat the exhaust gases after engine using Selective Catalytic Reduction (SCR). The SCR technology can cut emissions by well over 90%, to less than 2g/kWh. It is equally applicable to low-speed and medium speed engines. However, the lower exhaust temperatures of low-speed engines mean that the SCR unit must be located before the turbocharger.

For the SCR to operate, ammonia is required as a reducing agent to allow the chemical reaction to take place as the exhaust gases pass through the catalyst honeycomb. In practice a 40% aqueous solution of urea is used. Urea is favoured as a reducing agent because it is colourless, odourless, non-toxic, biologically harmless and can be transported and stored without problems.

The SCR system consists of a reducing agent storage tank, a reducing agent feeding and dosing unit, a reactor with catalyst elements and a control system. See also NOX Reducer System.

IMO NOx emission standards

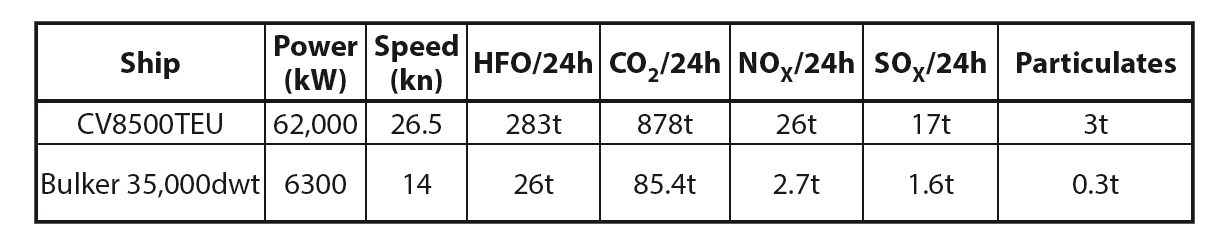

The NOx emissions limits in the IMO standards are expressed as dependent on engine speed. The IMO Tier 1 NOx emission standard applies to ships built from year 2000 until end of year 2010.

The IMO Tier 2 NOx emission standard entered into force on 1st January 2011 and applies globally for new marine diesel engines over 130 kW installed on ships which keel laying date is 1st January 2011 or later. IMO Tier 2 NOx emission levels correspond to about 20% reduction from the IMO Tier 1 NOx emission standard. This reduction is reached with engine optimization.

The IMO Tier 3 NOx emission standard will enter into force on 1st January 2016. The IMO Tier 3 NOx standard applies only for new marine diesel engines over 130 kW installed in ships which keel laying date is 1st January 2016 or later, when operating inside designated emission control areas (ECA). The IMO Tier 3 NOx emission level corresponds to an 80% reduction from the IMO Tier 1 NOx emission standard. The reduction can be reached by applying a secondary exhaust gas emission control system.

SOX emissions

SOX as a product of fuel oil combustion can be reduced by decreasing the sulphur content in the fuel. In October 2008 the Marine Environment Protection Committee (MEPC) of the IMO agreed on the progressive reduction of the maximum sulphur content in fuels used on board ships. The revised Marpol Annex VI regulations reduce the global sulphur cap to 0.5%, effective from 1st January 2020. The limit applicable in SOX Emission Control Areas (SECA) has been reduced to 0.1%, effective from 1st January 2015.

Exhaust gas cleaning systems that reduce the emission of sulphur oxides to the same extent are approved by IMO: see WÄRTSILÄ SOX SCRUBBER SYSTEMS.