"The new and improved performance management system, SkyLight 2.0, reduces emissions and fuel consumption. It also serves an example of how efficient digitalisation of the shipping industry is about developing services, not products."

“How long have you had your mobile phone? Six months? One year? You would probably laugh at the idea of using a 10-year-old mobile phone. But that is how long ship owners expect investments in new digital systems to last on their ships, to achieve return on their investments,” says Jan Wilhelmsson, Vice President, Commercial Shipping, in the recently acquired Eniram – a Wärtsilä company developing energy management and vessel performance systems.

Wilhelmsson is pointing at an inherent characteristic of digitalisation - things developing so fast that new gadgets become technological dinosaurs and outmanoeuvred by cheaper, more powerful models almost before the plastic wrapping comes off. Does that spell bad news for an industry looking to invest heavily in digitalisation of fleets? Well, yes and no!

A service for the future

“We need to sell digitalisation as a service, not a capital investment. And that is what SkyLight 2.0 does,” says Wilhelmsson enthusiastically.

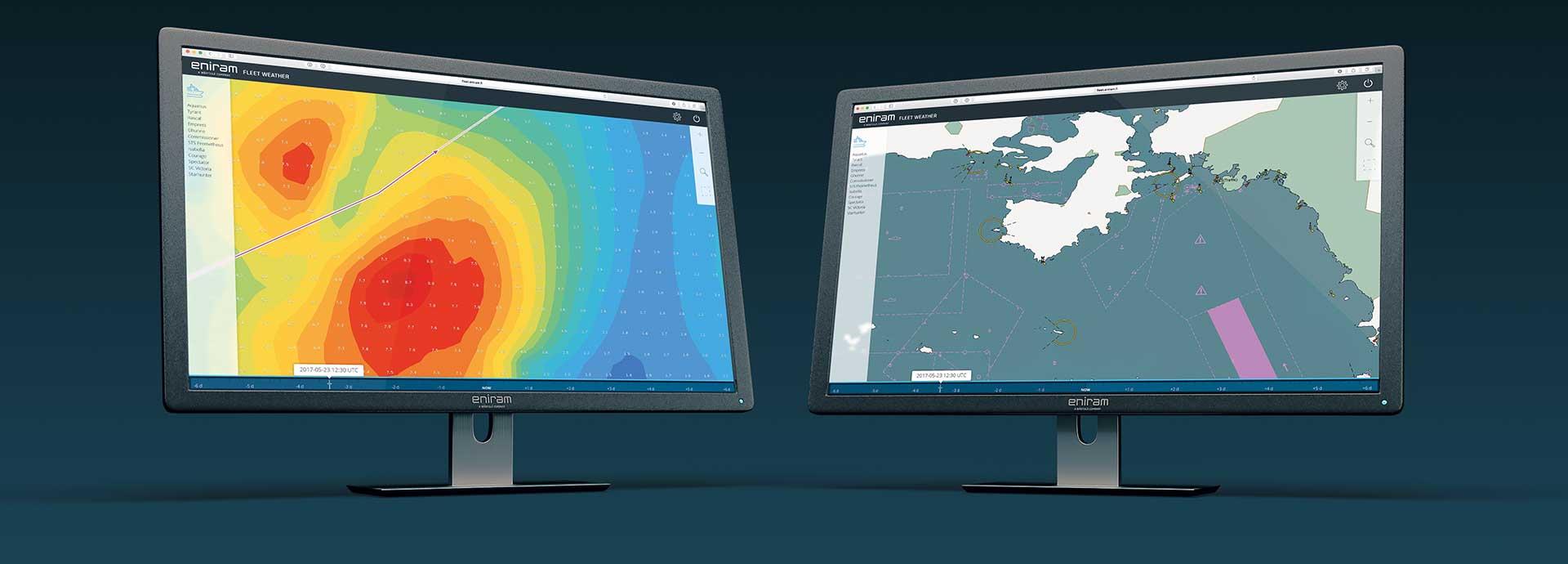

The Eniram SkyLight 2.0 is a cost-effective, next generation fleet performance monitoring system, customised for commercial shipping operators. It constitutes a vast improvement, providing more accurate data compared with manual performance reporting with Automatic Identification System (AIS). And even more importantly: it enables predictive analytics and proactive planning.

SkyLight 2.0 collects data about the ship’s movement every five minutes, which is combined with meteorological data, information about sea state and currents, as well as nautical maps and Google maps – to visualise a vessel’s route from economic, environmental, and safety perspectives, making it possible to plan for optimal fuel consumption and emission levels.

Cloud based services

This is all possible without investing heavily in hardware on board. All that the customer requires is a small transponder that is simply attached to the ship’s rail. The transponder autonomously transmits the data directly to Eniram’s data centre via Inmarsat Link, where performance modelling is carried out.

“It works like your cable TV subscription. You receive a small box owned by the cable company and you buy a subscription. When the system is updated, you get a new box, and when you want to end your subscription, you just return the box,” explains Wilhelmsson, a former ship’s captain himself, and the inventor of SkyLight.

“This cloud-based service model, where the hardware is located with us, and the customer subscribes to the analysis, makes it possible for us to continuously improve and update, without the customer having to exchange expensive hardware on every ship,” explains Wilhelmsson.

Continuous updates

Proving the point of fast moving technology, the first generation SkyLight was launched in September 2016.

“By the end of last year, it was beginning to become obsolete, and by spring 2017 the 2.0 update was launched,” says Wilhelmsson.

In the gap of only six months, SkyLight went from real time analytics to predictive analytics – taking a giant stride into the future.

“The use of data has changed, and must change. The shipping industry has moved from gathering historical information, to using data to give insight into what is happening now. The next step is to start using data to predict what happens in the future, to actively reduce waste, emissions, incidents and accidents. This is what SkyLight 2.0 is all about,” says Wilhelmsson.

“We expect SkyLight to be updated, expanded, and improved every six months,” he adds, stating that the system is developed in close dialogue with customers, and is adaptable to future unknowns.

It’s soon going to be time for an upgrade.