Thanks to new green regulations, the marine industry is gearing up to use Ballast Water Management Systems (BWMS) to protect the various ecosystems their ships operate in. Here are two things they must keep in mind to ensure that transition goes off without a hitch.

Comprising 70% of the earth surface, the world’s oceans and seas have sustained mankind throughout the ages. But in the process, it has also had to deal with pollution from industries and ocean-going vessels. And one of the more insidious forms of pollution has been that originating from Ballast Water dispersal.

Most Marine vessels routinely carry ballast water to provide stability to the ships and this water is usually taken on and discharged at various ports of call. This discharged water can introduce non-native species, bacteria and viruses to different eco-systems, threatening ecosystems.

This is why the International Maritime Organization introduced the Ballast Water Management Convention (BWMC). These global regulations mandate ship owners and operators to treat ballast water before it is released so that invasive microorganisms are not dispersed. The convention will come into force on the 8th of September 2017 and an estimated 30,000 ships above 400 Gross Register Tonnes (GRT) will be required to install a type-approved ballast water treatment system at their next mandatory International Oil Pollution Prevention (IOPP) survey.

Putting safety first

While ship owners are scrambling to ensure that the provisions of this convention are met, experts say there are two factors that must be kept in mind. The first is to ensure the safety of the equipment and the second is to provide the training necessary to operate these systems. Let’s take a look at the safety angle first.

Recently, the UK Health and Safety Executive issued a safety alert for ballast water treatment systems using electrolytic chlorination units, after an explosion occurred in a semi-submersible installation. Electrolytic chlorination feeds an electrical current to the ballast seawater and during this process, Chlorine, Sodium Hypochlorite, Sodium Hydroxide, Hydrogen and other chemical compounds are formed in the chamber through which the water passes.

Pressure-safe operations are vital to ensure the safety of these systems. Owner and operators using similar units have been urged to carry out a risk assessment of their equipment, via a hazard and operability study (HAZOP).

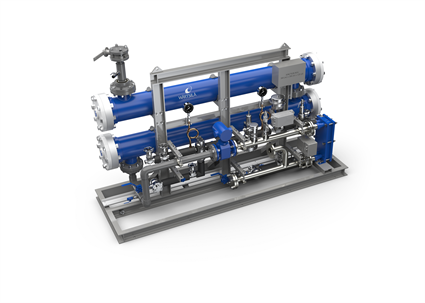

Wärtsilä is the only marine solution provider offering Ballast Water Management Systems with OEM lifecycle support on a global platform. Its Aquarius® EC BWMS system addresses this problem and minimises the risk of explosion, by incorporating a design that places operation safety at the very core of the product.

“The Aquarius-EC system incorporates a number of functions that aim to ensure operational availability of the system whilst maintaining high safety considerations,” says Joe Thomas, Director – Ballast Water Management Systems, Environmental Solution at Wärtsilä.

“For example, a gas detection system is included as standard and continuously monitors the presence of hydrogen gas, ensuring adequate dilution and safe venting through duty and standby air blowers. This aspect of the system has a separate power feed from the emergency switchboard to maintain operation even in the event of power failure on the ship,” he explains.

Training done right

Getting the right equipment in place is just one part of the puzzle. It is also important to train users to operate the equipment correctly. If the crew on a ship that has been equipped with a BWMS has not been trained, the equipment will not work at peak. And worse, it may be allowed to operate outside its design envelope putting compliance at unnecessary risk.

Owners and operators want their crew to have solid skills and knowledge so that their vessels can enjoy problem-free sailing. This is a potential knowledge gap that Wärtsilä is filling through Wärtsilä Land & Sea Academy (WLSA), which has 12 training centres in important shipping locations.

Here, ship crews are trained by trained engineers and specialists on various subjects including ballast awareness, operation and maintenance training. Specialised training is also provided to operate the Aquarius EC BWMS, with courses tailored to the individual needs of ship owners. The training is available in electronic format, with options available to have it take place face-to-face at the customer’s site or in classrooms and purpose-built BWMS equipment training facilities.

“BWMS training is a key element for both internal and external stakeholders,” says Thomas. “It is very important that the Wärtsilä global network have the necessary skills and competences to deliver support to customers as required and, in parallel, that BWMS operation and maintenance requirements become routine with the ships’ crew. Only with both these elements in place can the partnership be complete.”

As the marine industry and the world at large works towards a clean and green environment, it is these simple but effective steps, including choosing the right equipment and giving the right training, that will ensure that this is a smooth process.