JS INEOS Insight

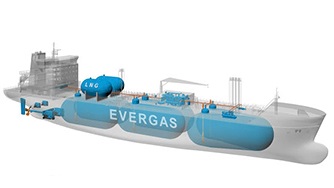

The first in a series of 27,500 cbm ‘Dragon’ class vessels ordered by Evergas, a world renowned owner and operator of seaborne petrochemical and liquid gas transport vessels, was delivered from the Sinopacific Offshore & Engineering (SOE) shipyard in China end of May 2015.

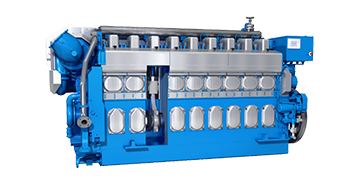

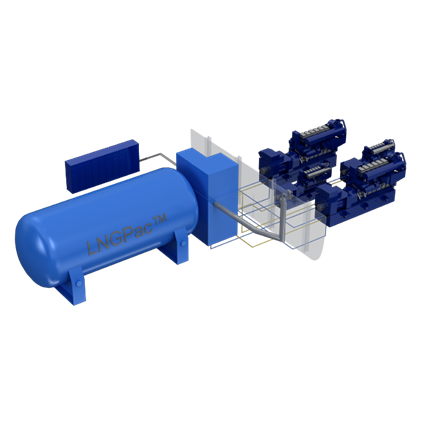

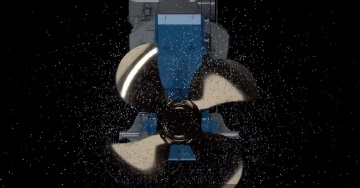

The vessel features a comprehensive Wärtsilä solutions package, including two Wärtsilä 50DF dual-fuel engines, Wärtsilä propulsion equipment including the gearbox, two Wärtsilä 20DF auxiliary generating sets, a Wärtsilä LNG fuel system and a Wärtsilä cargo handling system. The various systems are fully integrated to achieve maximum efficiencies. The order with Wärtsilä was placed in the beginning of 2013.

The Dragon class vessels are 180 metres long and 26.6 metres wide with a draft of approximately 9 metres. They represent the largest ethane carriers in their class in the world.

The delivery of the first in this series of the Dragon class vessels marks the beginning of a new era in the transportation of liquefied gases. The highly advanced technological solutions that Wärtsilä provides makes these ships the most modern and environmentally sustainable gas carriers ever built.

The ‘Dragon’ class ships are to be chartered by INEOS Europe for the transportation of ethane to Europe from the Mariner East project in the USA. The carriers are purpose built for the transportation of ethane, although they in addition can carry a wide range of petrochemical gases, LPG and LNG. Operational safety and efficiency, economic fuel consumption, and compliance with all applicable environmental regulations were the overriding considerations in the placing of the contract with Wärtsilä.

The various individual Wärtsilä solutions are integrated to form a fully optimised package. Furthermore, by engineering and supplying the complete cargo plant, the gas fuel supply system and the propulsion plant enables Wärtsilä to achieve optimal energy consumption efficiency for the entire vessel. This is clearly demonstrated, for example, where the LNG supply system is integrated with the cargo handling system so that it can be used to cool the cargo. In so doing, less energy and power is needed to keep the cargo temperature suitably low, thus providing a more efficient and environmentally sound overall system.