Wärtsilä retractable thrusters for unmatched manoeuvrability and station keeping

Wärtsilä retractable thrusters are designed for reliable operation in the most demanding environments. Their eight-degree tilted propeller gearbox is an innovation that makes the delivered thrust more effective. As a result, these thrusters are the ideal choice for reliable station keeping.

Choose from a complete family of WST-R thruster types, and your vessels can exceed the performance levels required in today's competitive operating environment. Wärtsilä WST-R thrusters are an ideal solution for the following kinds of vessels, for example:

- wind turbine installation vessels

- offshore support vessels

- offshore construction vessels

- shuttle tankers

- heavy lift vessels.

In general, any vessel that requires reliable station keeping performance will benefit from the WST-R thrusters.

Watch this video to learn more about Wärtsilä thrusters and propulsion controls for heavy-duty dynamic positioning:

Five critical features of retractable thrusters

A retractable thruster that combines superior performance and efficiency will have five critical features:

1. Effective thrust with minimal losses.

Thrusters must be able to keep the vessel in a steady position whatever the conditions.

Wärtsilä’s retractable thrusters have a revolutionary 8-degree downwards tilt on their propeller shaft. Because the tilt minimises the thruster-hull interaction, the available thrust increases by 15–20% compared to non-tilted thrusters. You will need less installed power to get the same dynamic positioning (DP) capability.

2. Optimisation and a holistic approach.

There are so many different variables in designing the ideal thruster system that a holistic approach is the only way to go. You will want the size, weight and number of thrusters optimised and tailored to the unique needs of your vessel early in the design phase.

OPTI Design methodology and OPTI-DP™ Engagement Tool are ideal solutions for optimising and tailoring your thruster system.

3. Reliability and easy maintenance.

When your vessel is working far out at sea in high waves and harsh conditions you need your thrusters to be reliable. If you do need to carry out repairs, retractable thrusters with easily accessible components can be fixed even when the vessel is afloat.

Wärtsilä’s retractable thrusters meet these requirements. Their design is based on extensive experience with more than 300 retractable thrusters delivered over 50 years.

4. High efficiency across the board.

For your thruster to be fuel-efficient, it needs to be as light as possible to leave more room for payload.

With the right design choices and the help of tools like Wärtsilä’s in-house OPTI-DP™ Engagement Tool, you can save 30–40 tonnes per retractable thruster.

5. Safety and redundancy built in.

With expensive assets and crew working in harsh conditions offshore, safety is non-negotiable.

Wärtsilä’s thrusters are reliable, delivering safe and efficient station keeping performance.

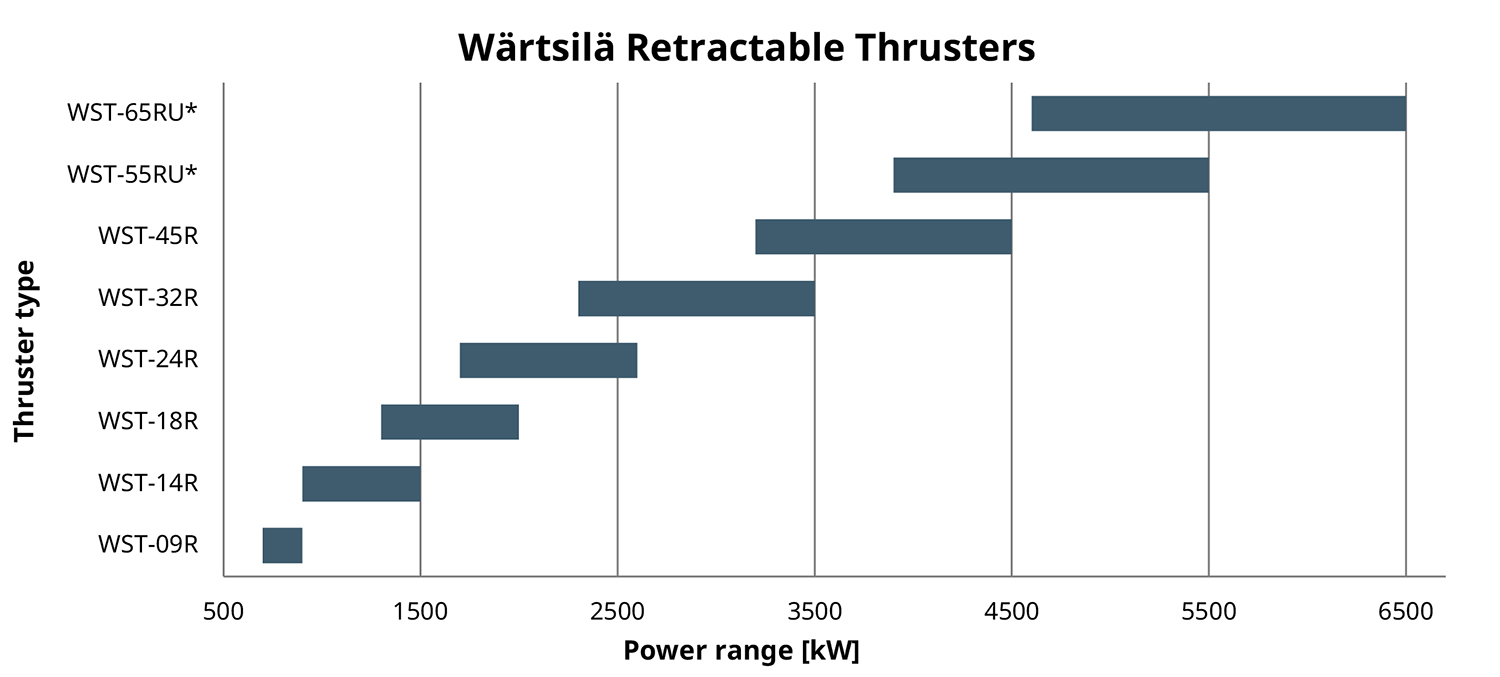

Retractable thrusters family from Wärtsilä

- WST-09R

- WST-14R

- WST-18R

- WST-24R

- WST-32R

- WST-45R

When you need a dynamic positioning (DP) system, Wärtsilä Retractable Thrusters are second to none.

- Power range between 750 kW and 6500 kW in both L- and Z-drive options

- Minimised area footprint in the vessel

- Full retraction reduces the vessel’s resistance and makes it possible to operate in shallower waters and ports

- WST-55RU

- WST-65RU

The Wärtsilä underwater mountable thrusters are designed for safe and reliable operation in demanding conditions. The proven underwater mounting method means that maintenance on the thrusters is possible even when the vessel is afloat. This way, you will avoid dry-docking for thruster maintenance.

Find the family of WST-R retractable thrusters in the graph, which also shows the power range for each type:

*units available on request

Customer cases

Discover the benefits others have already gained from efficient, high-performing thrusters.

Plug and Play thrusters are easy to install, saving time and effort

As global demand for renewable energy increases, the Prysmian Group selected Wärtsilä’s retractable thrusters for the worlds most advanced cable laying vessel yet – the Leonardo Da Vinci. The Leonardo Da Vinci is a DP3 vessel and can handle cable laying operations to depths of up to 3,000 meters, in some of the world's most extreme weather conditions.

The WST-R (up-to WST-32R) are assembled and pre-aligned in Wärtsilä factory. The pre-alignment makes the thrusters easier to install. This saves time for the shipyards.

Insights on thrusters and propulsion

Discover these insightful articles – an easy way for you to build your knowledge of thrusters and other propulsion solutions.

Why choose Wärtsilä

Choose retractable thrusters from Wärtsilä, and you will enjoy important benefits. For example:

- Because of the eight-degree tilted propeller shaft, these retractable thrusters are the most efficient in the market. Their performance in station keeping is excellent, and they can deliver up to 20% more effective thrust than conventional non-tilted thrusters.

- Wärtsilä has the expertise to use hydrodynamics and computational fluid dynamics CFD to identify the ideal configuration and power requirements of the thruster system for your vessel’s unique operating profile. Because of this detailed insight, the power requirement can be calculated, not only estimated. This can reduce the cost of the total power train configuration, saving you money.

Put your trust on the industry’s widest range of retractable thrusters, from 750 kW to 6.5 MW, plus the technology and the hydrodynamic expertise to help design and deliver optimal thruster solutions.