A leading supplier of complete cargo handling systems for gas tankers

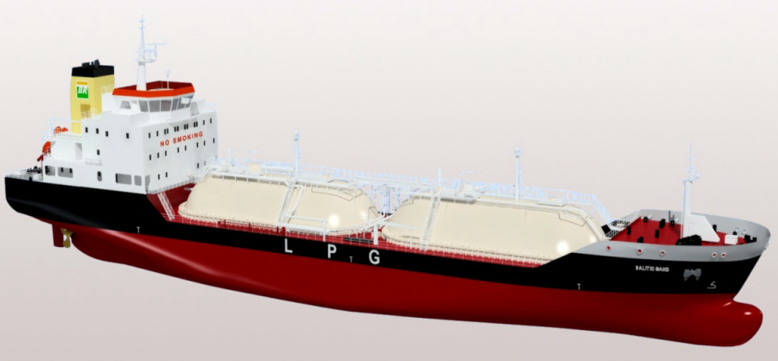

Wärtsilä is the leading supplier of complete cargo handling systems for gas tankers. Most of these vessels are fully pressurized with cargo tank volumes typically in the range of 1,000 cbm to 13,000 cbm, and Wärtsilä offers state-of-the-art cargo handling solutions for this segment – designed to reduce operating costs, improve vessel EEDI and reduce overall GHG emissions.

Our field proven system is based on experience from a large number of systems delivered and ships in operation. It utilizes the best aspects of both fully pressurized and semi-refrigerated designs, including possible reduced cargo tank design pressure and the use of cargo chiller units.

The system is capable of handling LPGs, propylene, ammonia, DME, butadiene, VCM and certain chemical cargoes. Our delivery includes system engineering, material supply, cargo tank design / supply, supervision, and commissioning assistance.

Technical data

Wärtsilä’s system is designed for safe, efficient and operator friendly handling of applicable cargoes on fully pressurized gas carriers with capacities between 1,500 m3 and 13,000 m3.

The system is normally designed with two cargo segregations. Cargoes can be loaded in pressurized condition, ensuring faster loading. While the typical design pressure for fully pressurized cargo tanks is 18 bar(g), our system can also features chiller units – allowing cargo tanks to be designed for a lower pressure. This enables significant weight savings and allows an increased cargo loading rate of up to 98%. The solution is also prepared for integration with our gas fuel supply system (LFSS), which significantly reduces overall GHG emissions from the vessels.

The deck arrangement is designed for logical and easy access to all equipment, and most weather exposed instruments and major machinery are protected from the environment for improved durability and lifetime performance. The piping layout is designed primarily for gravity drainage of liquid back to cargo tanks, and the safety system comprises state of the art vents, gas detection and ESD`s.

A control system, offered in different versions, is part of the scope. This can be delivered with interfaces to subsystems like an inert gas system, load computer or LFSS, and integration of the ballast system is applicable.

Applications

Fully pressurized gas carriers transporting LPGs, propylene, ammonia, DME, butadiene, VCM and certain chemical cargoes.

Key benefits

Based on our market leading gas competence, decades of experience and an unmatched reference list, Wärtsilä’s cargo handling system offers the best solutions for fully pressurised gas carriers.

The system is designed for flexibility and is easily adapted to each shipowner’s specific cargo requirements. It enables weight reductions and allows an increased cargo loading rate of up to 98% – enabling cost savings and higher revenues.

Our system also contributes to improved EEDI, annual carbon intensity indicator (CII) and ship energy efficiency management plan (SEEMP) figures.

A well-educated crew is key to safe and correct operation of a cargo handling system, and with our technology we offer training courses developed by Wärtsilä Gas Solutions Academy.

Integration with Wärtsilä’s Operim® software. The Operim® enables remote monitoring and diagnostics, contributing to higher system uptime.

As part of the Wärtsilä Corporation, Wärtsilä Gas Solutions offers its customers access to the industry’s most extensive global network of services and workshop facilities.

Contact our 24/7 customer support at +47 815 48 500. For spare parts, please e-mail us with the equipment serial number or the name of the installation at moss-spares@wartsila.com (Inert Gas Systems) spares.wgs@wartsila.com (all other products)

For technical support & service, please email us with the equipment serial number or the name of the installation at services.wgs@wartsila.com.

Equipment serial number is taken from the equipment nameplate and includes all letters and numbers as given on the equipment nameplate.