Fuel conversion gives your ship fuel flexibility

In the short term, ship owners can comply to IMO’s CO2 targets by optimising vessel operations and implementing efficiency-boosting technologies. But IMO's tough targets for 2030, 2040, and 2050 require extra effort. Switching to an alternative future fuel and investing in fuel flexibility immediately cut the carbon, SOx and NOx emissions. It will also achieve compliance with regulations such as EEXI.

When investigating a fuel conversion for an existing ship, there are five important considerations.

Ensure the success of your conversion

How to succeed in marine fuel conversion? Five things to take into account with a marine fuel conversion in this handy eGuide.

Download the eGuide now!

The number of available fuels will increase

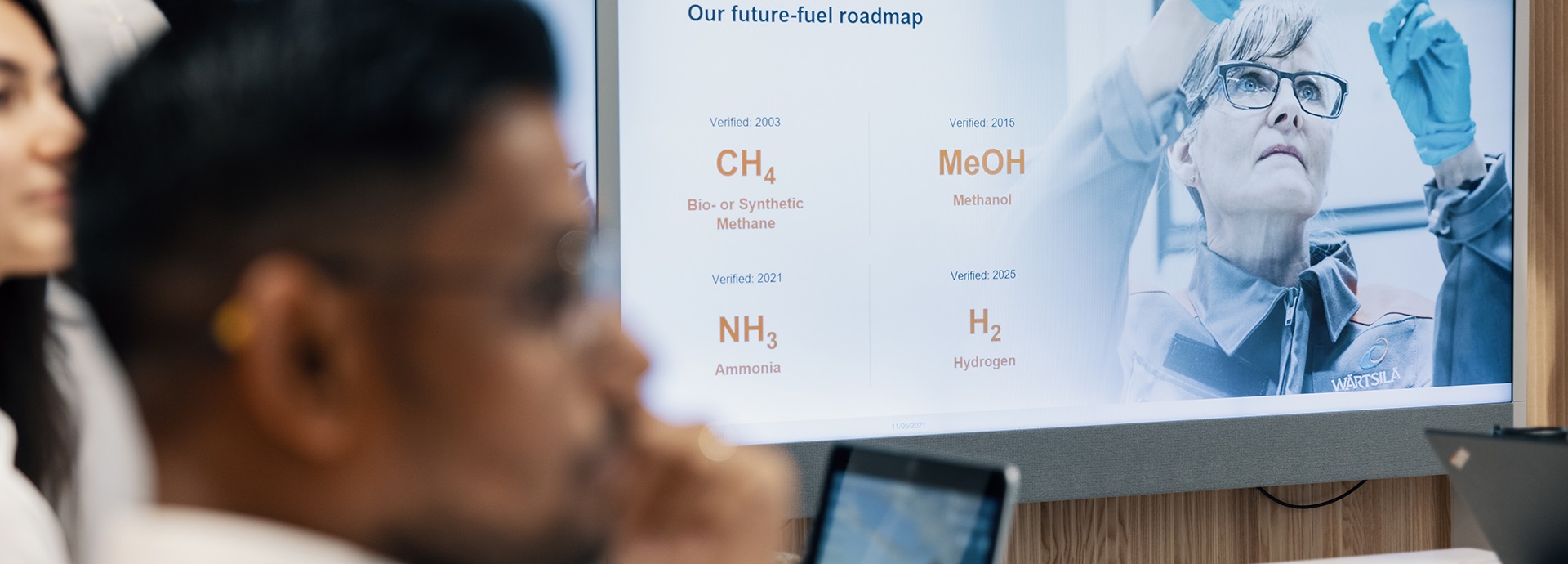

Investing in fuel flexibility and the combustion engine will mitigate compliance and business risks introduced by future fuels. There is no one single future fuel – there will be a whole variety of fuels in use. To power the shipping in the future, Wärtsilä is investigating wide range of fuels and developing a wide range of engine and fuel gas supply systems to help ship owners navigate the route to reduced GHG emissions – whatever fuels are chosen.

Fuel conversions – complete systems regardless of fuel

Wärtsilä has the technology needed to use most future fuels today and development is on-going for others. We are also investing heavily in developing fuel conversion and retrofit solutions. There are already a variety of retrofit solutions that can be implemented on both 4-stroke and 2-stroke engines.

Sustainable fuels for shipping by 2050 – the 3 key elements of success

How to decrease the environmental footprint of shipping? What are the key actions that will keep the shipping industry on course to achieve net-zero by 2050?

Download this research-backed report on future fuels in the marine industry to find out:

Find the best way to adopt alternative fuels for your vessel fleet

Are you thinking about adopting future fuels for your vessels but unsure how to start? Perhaps you need to know whether to convert your existing vessel to run on alternative fuels, or to invest in a newbuild.

For an existing vessel, the study outlines the modifications needed to accommodate engines capable of combusting your future fuel of choice as well as the related fuel storage and auxiliary systems. The study includes preliminary engineering drawings for the layout of the key equipment needed and key piping diagrams as well as a written report providing valuable high-level information on the conversion.

What does a feasibility study include?

- Engine conversion plan

- Recommended solutions for fuel storage onboard

- Estimated structural modifications for the vessel

- High-level weight change calculations

- Automation and control system modifications

- Operational comparisons of using alternative fuel vs diesel

- A preliminary high-level cost estimate and project schedule

- Risk assessment.

Interested in learning how sustainable fuels could work for your vessel or fleet? Complete this form and a Wärtsilä expert will get in touch with you to start the discussion.

The only way an asset can return value beyond 2030 is if it can adapt to low-carbon and green fuels. Fuel flexibility is the key to enable this transition.

Get more information from our references

Articles

Related solutions

Take your easiest next step! Get in touch and let’s discuss your options, or for a full and no-obligation feasibility study.