Reducing VOC emissions primarily benefits our environment and climate

Volatile organic compounds (VOC) are light components of crude oil, which evaporate during loading operations or during the carriage of high-volatility crude oil cargoes. Traditionally this cargo vapour has been vented into the atmosphere to prevent the cargo tank pressure to exceed the design pressure. Such venting represents both an environmental problem and a great loss of energy. In total, the emissions of VOC from global sea transportation account for a total of more than 5 million tonnes per year.

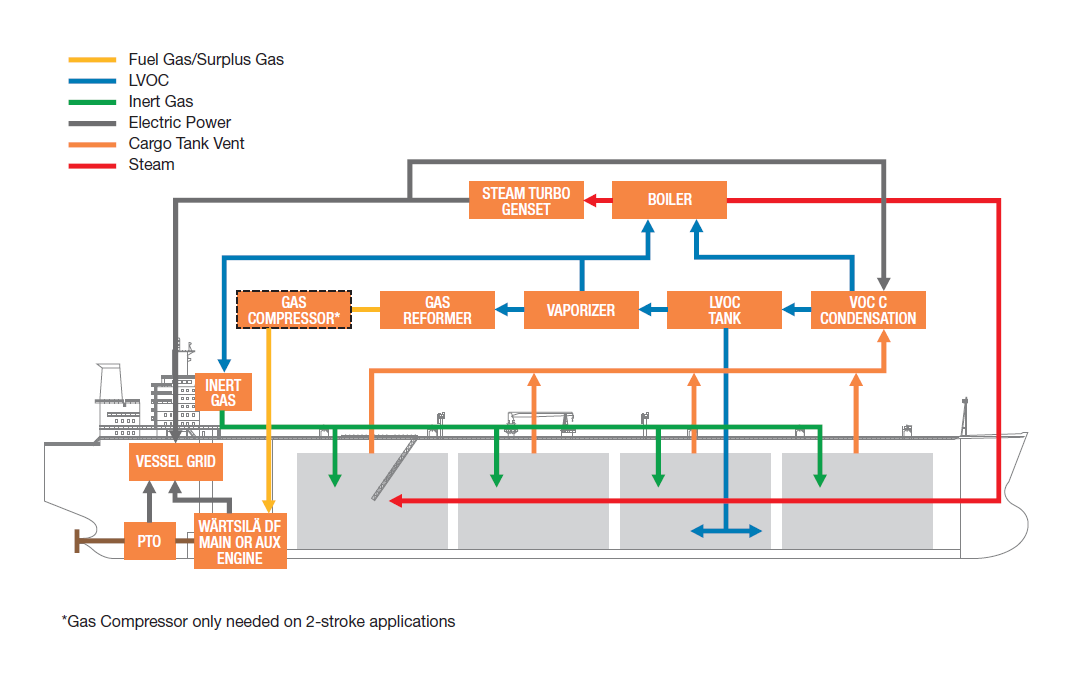

The Wärtsilä VOC recovery system not only prevents these harmful compounds from being emitted to the atmosphere, it also condensates the VOC into two fuel fractions. One is used to power the recovery system itself– making it self-supplied with energy. Today, several shuttle tankers in the North Sea are utilizing this technology to increase the sustainability of their operations.

Technical data

The recovery of VOC is accomplished by leading the crude oil cargo vapour into the VOC recovery system, then using a condensation process to separate the heavier hydrocarbon fractions of the gas (Liquid VOCs – LVOC). These are stored in a pressurized storage tank on board. LVOC is a light hydrocarbon fuel that can be utilized as a clean fuel in power generating modules and inert gas generator units.

The lighter non-condensable hydrocarbon fractions (Surplus VOC – SVOC) are fed to the recovery system’s power generating module – ensuring 100 % VOC recovery with zero emissions.

Applications

In the oil and gas industry, our main VOC recovery system is most typically used onboard shuttle tankers. Wärtsilä has also in cooperation with Vaholmen VOC Recovery developed a system, where the VOC Recovery Unit is installed on a DP vessel, typically a PSV and serves crude oil tankers loading at buoys, sea islands, terminals or other.

Adding to the VOC recovery system, Wärtsilä can offer different VOC utilization solutions where the recovered and liquified VOC is used for power production. This solution provides environmental benefits with reduced VOC emissions, and economic benefits with fuel cost reductions of up to 40%.

Key benefits

Reducing VOC emissions primarily benefits our environment and climate. But recovering the cargo vapor can also contribute to more sustainable use of energy and increased profitability for vessel and cargo owners.

The environmental impact of VOC emissions is significant, as the emitted gas consists of a range of hydrocarbons – including methane. Methane is a powerful greenhouse gas with a global warming potential that is 28 times higher than CO2. The non-methane fractions of VOC, known as NMVOC with a GWP 4 times higher than CO2, react in the presence of sunlight with nitrous oxides and create a toxic ground-level ozone and smog layer which has detrimental environmental effects on vegetation and on human health – particularly on the eyes and lungs.

Vaholmen VOC Recovery

This is a design revolution

Press releases

Contact our 24/7 customer support at +47 815 48 500. For spare parts, please e-mail us with the equipment serial number or the name of the installation at moss-spares@wartsila.com (Inert Gas Systems) spares.wgs@wartsila.com (all other products)

For technical support & service, please email us with the equipment serial number or the name of the installation at services.wgs@wartsila.com.

Equipment serial number is taken from the equipment nameplate and includes all letters and numbers as given on the equipment nameplate.