Safer navigation, reduced crew workload and improved transparency are at the top of the wishlist for tanker operators. Zeaborn Ship Management achieved all three with the fleetwide introduction of Wärtsilä’s Fleet Optimisation Solution on their managed wet fleet.

“If a container vessel loses 1,500 boxes, it probably will make the news,” says Torsten Iborg, Fleet Navigation Officer at Zeaborn Ship Management. “If a tanker spills 1,500 tonnes of oil, it definitely will grab the headlines.”

It is a pointed reminder of why safe navigation matters for tankers - and why Zeaborn is upgrading its 12-strong managed product tanker fleet with Wärtsilä Voyage’s Fleet Optimisation Solution (FOS) digital navigation package.

Image source: Zeaborn Ship Management

Just over a year since the former CPO Tankers fleet was brought into the group, Zeaborn has already used new digital tools to streamline several key areas of the business. These include lubricants purchasing, maintaining and reporting its vessels’ hazardous materials inventories and – in response to the new work regime imposed by the pandemic – a hybrid system of remote and on-site working for staff at its headquarters in Hamburg. Now it is bringing digital efficiencies to the fleet itself.

Digitalisation must support our strategy and overarching business goals. The main things you look for as a ship manager are to improve safety, increase efficiency and reduce costs while managing vessels according to owners performance and quality expectations.

- Matthias Ritters, Managing Director of Zeaborn Tankers

FOS is a connected Electronic Chart Display and Information System (ECDIS), integrating voyage planning functions into the mandatory electronic chart system and enabling a ship-to-shore link from the system. It is a versatile tool, particularly when combined with data from other ship systems and external sources; dedicated modules enable a range of functions including route optimisation, fuel optimisation, energy efficiency reporting and charterparty compliance monitoring.

For Zeaborn, it is the navigational benefits that are the most important. Automated route planning is one illustration. Manually charting the waypoints and deviations for multiple port calls can take a navigation officer up to five hours, on top of a daily eight-hour watch at sea or a gruelling 12-hour shift at port. Automatic plotting can reduce this to less than half an hour, dramatically reducing the potential for fatigue among bridge officers and cutting the risk of human error in navigation.

Mobile ECDIS

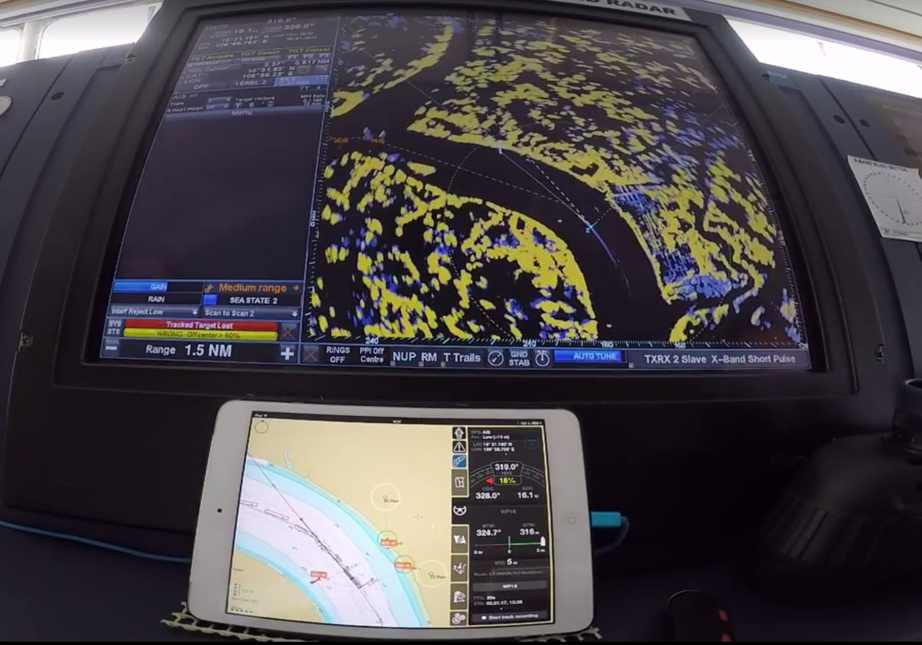

Another element of the FOS package will be welcomed by Zeaborn’s customers and their charterers as well as by the crew. The BridgeMate tablet features an independently backed-up ECDIS that can be used anywhere on the vessel to give officers full visibility of where the ship is and where it is heading. As well as providing redundancy if bridge systems or power should fail, the mobile tablet means that navigation officers can access ECDIS from the wings of the bridge while performing manoeuvres.

Torsten Iborg explains: “As a captain, I want to see what the ship is doing. When I manoeuvre from the wings I have only my eyes and instruments showing revolution and rudder angle. The BridgeMate gives access to information from the ECDIS, including rate of turn, speed from the bow, speed from the stern as well as movement of the vessel generally. This makes manoeuvring in port much easier, and much easier to plan.”

This is not just a ‘nice to have’ device. Oil majors are increasingly focusing on navigational safety equipment, specifying that the vessels they charter should have rate of turn indicators on the wings. The BridgeMate satisfies this requirement. The mobile device provides even more reassurance; in the case of a pirate attack, the crew can retreat to the safety of their citadel and – providing they have brought the tablet with them – can still know where the vessel is and where it is heading.

Remote visibility

Another key advantage of the FOS digital navigation package is the real-time ship-to-shore connection and the extra visibility this gives about what is happening on the vessel.

“We have very good people on our vessels,” says Mr Iborg. “But it's very difficult if you only see on AIS where the vessels are and what they are doing.”

FOS gives us the opportunity to look a little bit deeper. We can check the voyage plan and the weather and increase the safety of the vessel.

- Torsten Iborg, Fleet Navigation Officer at Zeaborn Ship Management

“So, when there is an alarm onboard, I see the alarm as well. If the vessel crosses a safety contour, for example, there's an alarm created in the ECDIS and I can see what is happening onboard and how they deal with the situation.”

Remote visibility will also allow Zeaborn to be more flexible about its approach to both navigational auditing and training. Navigational audits are an essential practice for ensuring that safe procedures are kept and that equipment is in good working order. Traditionally the audits have been limited by when auditors from the ship manager or third parties can get aboard. In the current pandemic, this has become even more restricted. But with the installation of FOS comes the ability for remote auditors to ‘play back’ navigational information to see how the vessel responded in a particular situation. While Mr Ritters explains that this would support rather than replace onboard visits from auditors, the functionality increases the options open to the navigation team.

Image source: Zeaborn Ship Management

Image source: Zeaborn Ship Management

The same ‘playback’ mode will also add value to training and incident investigation, both performed by combining historical data from FOS with Zeaborn’s simulation capabilities.

Mr Iborg explains: “In case of an incident, FOS is perfect. We can use data directly from the system, put it in the simulator and see exactly what was going on at the time. We have the AIS data from the other vessel so we can see directly how our own vessel was acting.”

Customers in the loop

Enhanced transparency will not only benefit Zeaborn. The company already has a portal through which customers can receive the information and reporting that they expect, often in real time and tailored to their particular requirements. Mr Ritters explains that this portal is constantly being developed as customer needs evolve, with new features being added. Although it is early days, he sees the potential to incorporate navigational data from FOS into the portal.

“If voyage data is shared with other stakeholders, we see big potential for further efficiencies and for safety. When we are looking into new tools these are features, we would expect to see. Once we feel confident with the tool and the functionality, then we will engage with our customers and see what can be shared and what information is relevant for them.”

While navigation is at the core of FOS, its capabilities are much wider when combined with other information sources on the ship, externally or both. One further FOS feature of potential interest for Zeaborn is monitoring and optimising energy efficiency on vessels, says Mr Ritters.

If you have better access to better data then you can both execute voyages more energy efficiently and benchmark how the voyage has been performed, to learn how to improve efficiency.

- Matthias Ritters, Managing Director of Zeaborn Tankers

“We already have systems in place to monitor fuel and energy efficiency, so a next step would be to decide whether to link the systems or maybe use additional functions on the energy efficiency side of the Wärtsilä solution.”

That decision will come later. The first step is to implement FOS, get crews and office staff familiar with the system and put the focus on navigation and navigational safety. Although commissioning the systems has been more challenging than usual due to pandemic restrictions, the company is confident that FOS will be running on all 12 vessels in the next few months. The simplicity of FOS was a key differentiator when Zeaborn was selecting systems meaning that crew should be able to learn how to make the most of it quickly. And the fleetwide roll-out will also enable crews to switch between vessels easily without having to learn a new system.

As Mr Ritters explains, Zeaborn’s approach to digital innovation is grounded in how new tools help it to reach its business goals. By improving navigational safety, reducing crew burden and improving transparency of onboard operations, FOS is set to become a key part of the company’s drive towards safer and more efficient management of its customers’ fleets.

.tmb-448x262.jpg?Status=Master&Culture=en&sfvrsn=38658644_1)