One often reads or hears people say that floating storage and regasification units (FSRUs) are more economical solutions compared to land-based terminals. What is the basis for such a statement? Is it accurate? To answer that question, one needs a short history lesson to understand the past.

History

Floating storage and regasification units (FSRUs) as a concept were developed in 2005, driven by the need for a fast delivery LNG storage and regasification solution. The first FSRU was not a new-built unit but a conversion of an existing LNG carrier (LNGC) by a shipyard. The concept was a success, and more projects were developed. These first FSRU projects had a short delivery time in comparison with land-based terminals, which was the main driver. Simultaneously land-based terminals were built for long-term operations.

Looking at the installed FSRUs today, most of them have a good reason for being developed: some are political, while some are based on location, schedule, public safety or environmental constraints. These factors have been the determining factors for

the selection of FSRUs versus land-based LNG terminals. So, can one say that FSRUs compete with land-based solutions? No, not really; they are more a complement to each other, since the projects are very different. The values FSRUs bring to the LNG

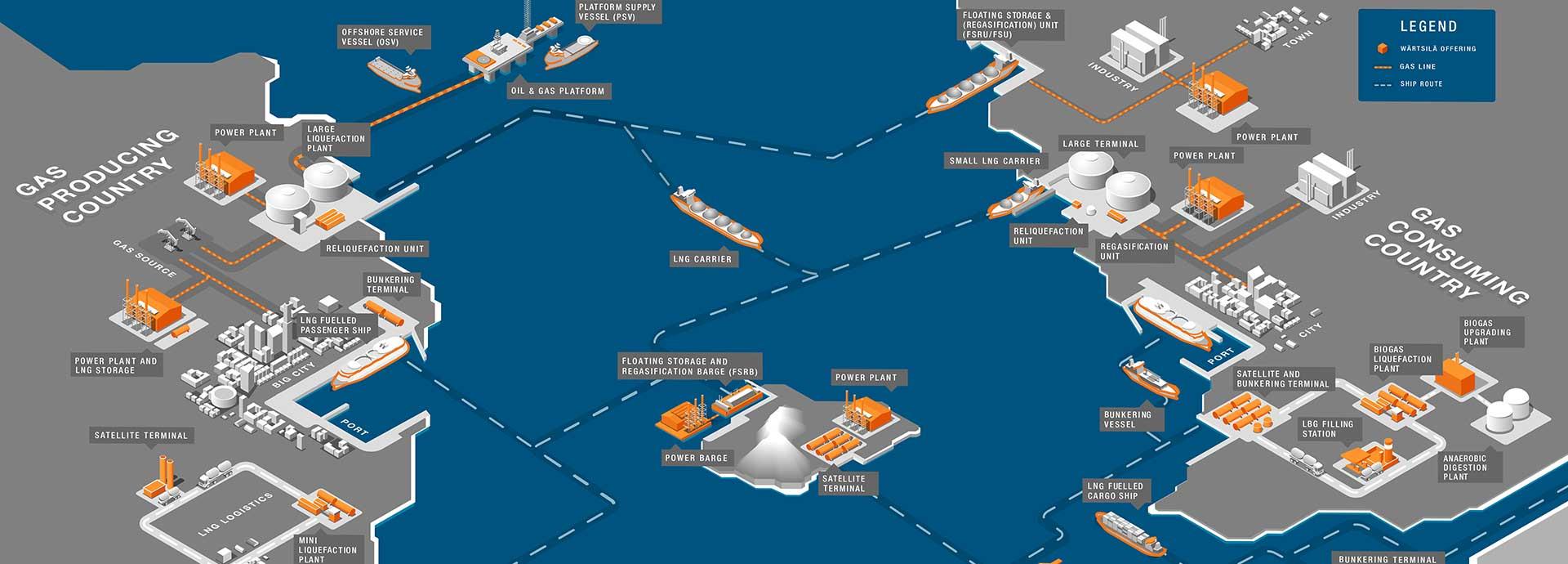

value chain are not the same that land-based terminals do. (Figure 1)

Fig. 1 - LNG terminal comparison. Historical concepts (mooring systems and layouts).

The FSRU concept

The most common concept for FSRUs is mooring at shore (> 60% have jetty + access trestle). This is the conventional FSRU and commonly referred to when comparing with land-based terminals. There are also concepts that use other kinds of mooring technology. These are, generally, more expensive systems that are used where conventional jetty structures are impractical to construct or are not permitted.

In general, land-based LNG terminals are more multifunctional terminals, since they also have LNG onshore. These functionalities might be reloading of LNG feeders, bunkering of vessels and LNG tanker truck loading systems, which may be of importance in certain markets and infrastructure systems. The majority of the FSRUs are also located onshore, so the functionalities given could be adapted also to the FSRUs if there was a need for modifications in the existing infrastructure. The most common FSRU concepts are single-purpose terminals with a national pipeline gas supply or large-scale power generation.

That said, developing a project with FSRU technology limits one to a fixed storage volume and send-out volumes suitable for a national pipeline. However, flexibility can be achieved if there is a possibility of sharing the units with multiple locations

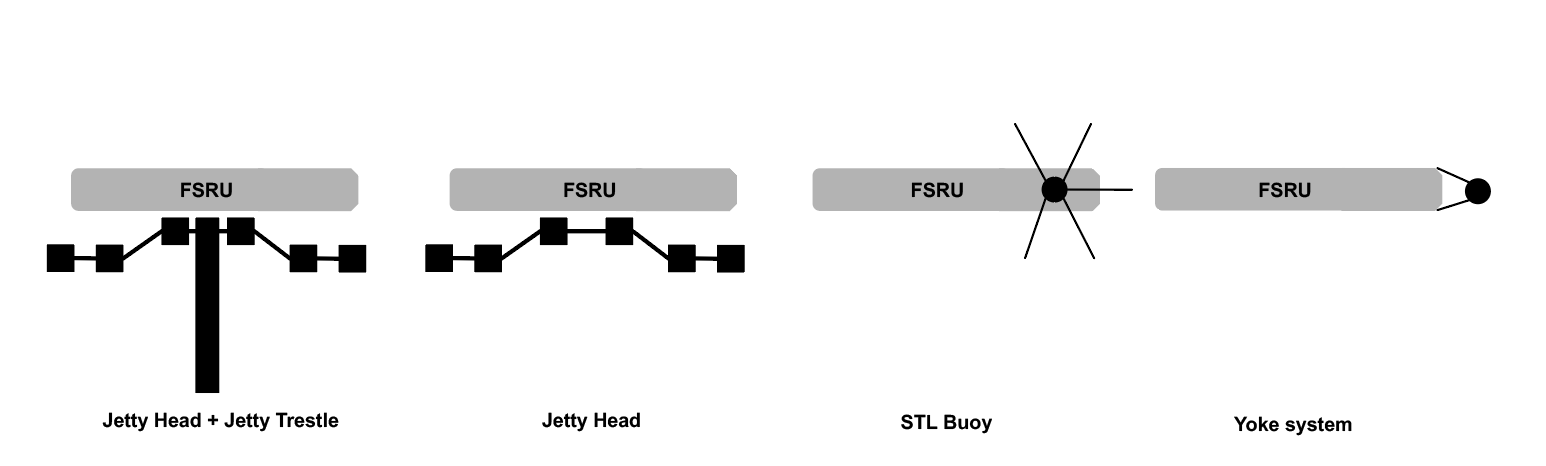

when there are seasonal send-out needs. (Figure 2)

Fig. 2 - LNG terminals worldwide

CAPEX vs. OPEX

What favours floating solutions is the upfront investment, unlike the case in a land-based solution. Financing is key to success when comparing with the use of chartered units where it will be on OPEX.

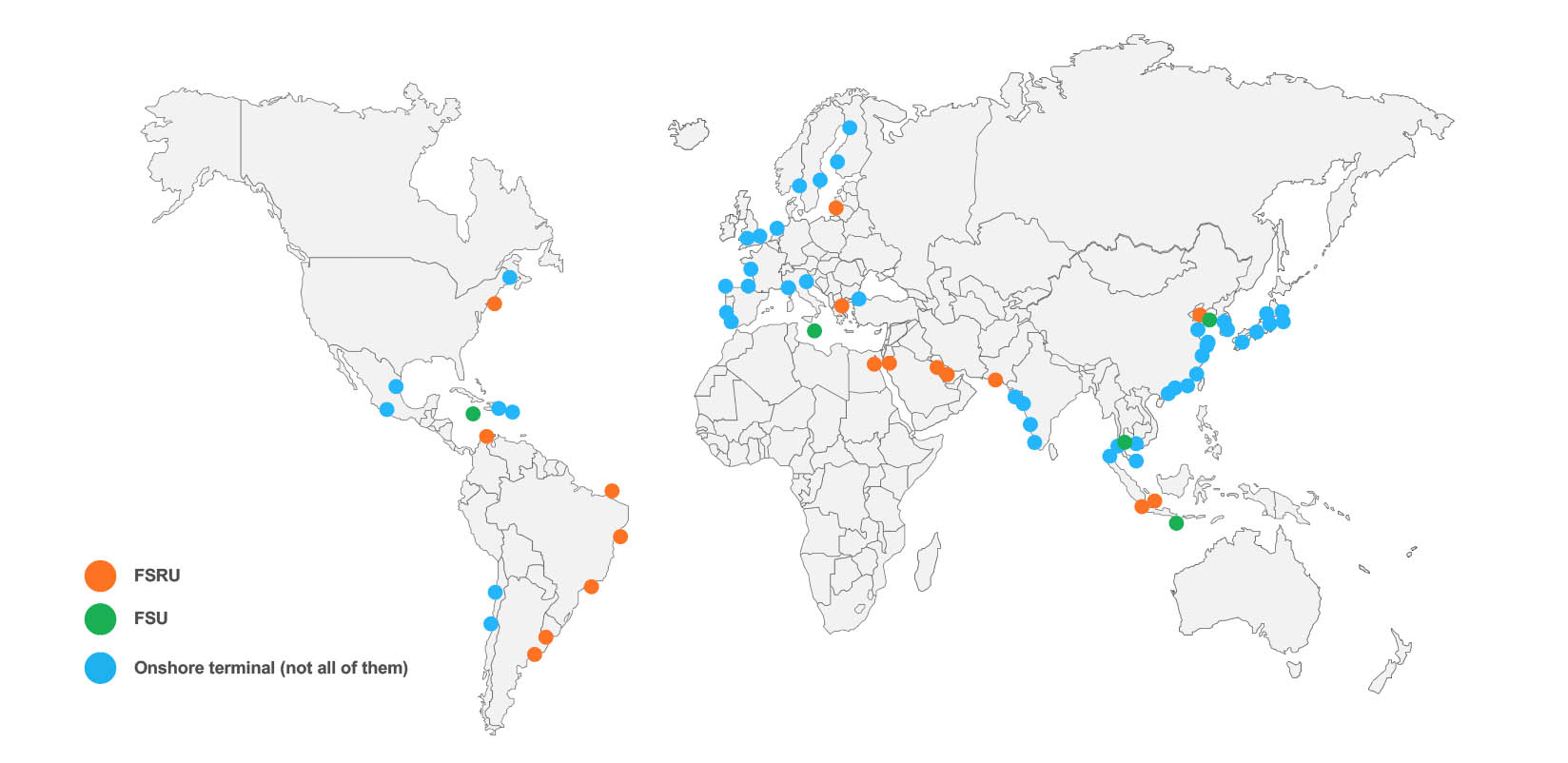

Currently (March 2018), the charter rate for an FSRU is USD 80,000–120,000 per day depending on time charter period, location and size. This easily adds up to MUSD 29.2–47.5 on an annual basis. This is for the charter, e.g., the FSRU, insurance, crew and maintenance, and on top of this come the regasification costs. Depending on regasification technology (sea water / glycol or steam system) and capacity, we need to add another USD 15,000–25,000 per day for a 300–500 MMSCFD send-out regasification system.

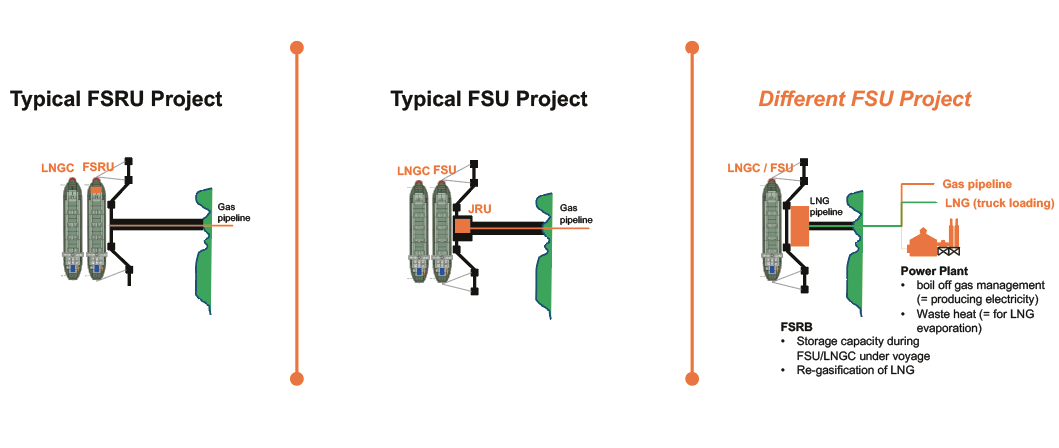

During the last few years, another comparable system, a floating storage unit (FSU), has been used in several projects.

These units are equipped only for storage. The regasification system is installed either on a jetty, on a separate floating storage regasification barge (FSRB) or on a land-based terminal. The fact that idle LNGCs are available in the market now enables faster delivery of these projects. However, conventional LNGCs (also known as “old ladies”) are currently based on charter rates of USD 25,000–40,000 per day, and when it comes time to replace the LNGC, there’s no telling what the charter rate would be. (Figure 3)

When constructing a land-based terminal, one does not have any charter costs for storage and regasification, since the costs of this functionality are part of the CAPEX cost of the terminal.

The cost of an engineering, procurement and construction (EPC) project of course depends on many parameters, everything from send-out capacity and storage size to location (bathymetry and met-ocean conditions). Assuming a typical location representing

a majority of the FSRUs, e.g., on shore at a jetty head, we can compare the CAPEX and OPEX costs of floating versus land-based LNG terminals.

Fig. 3 - Daily equivalent costs

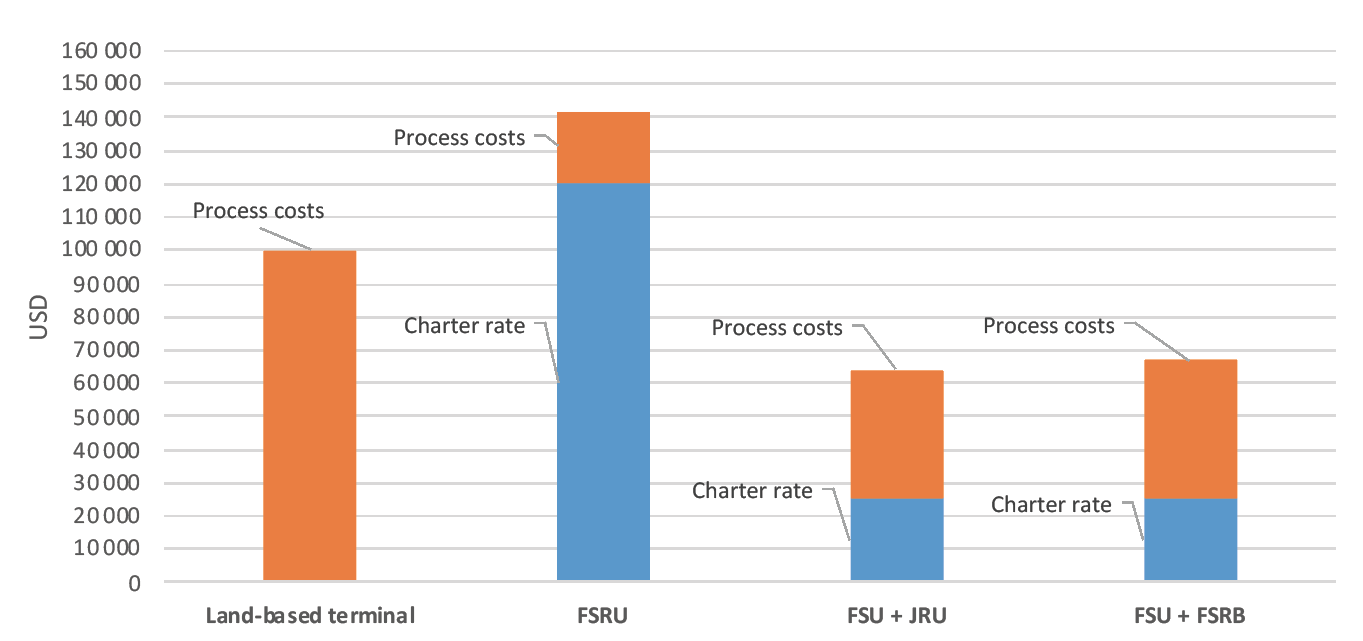

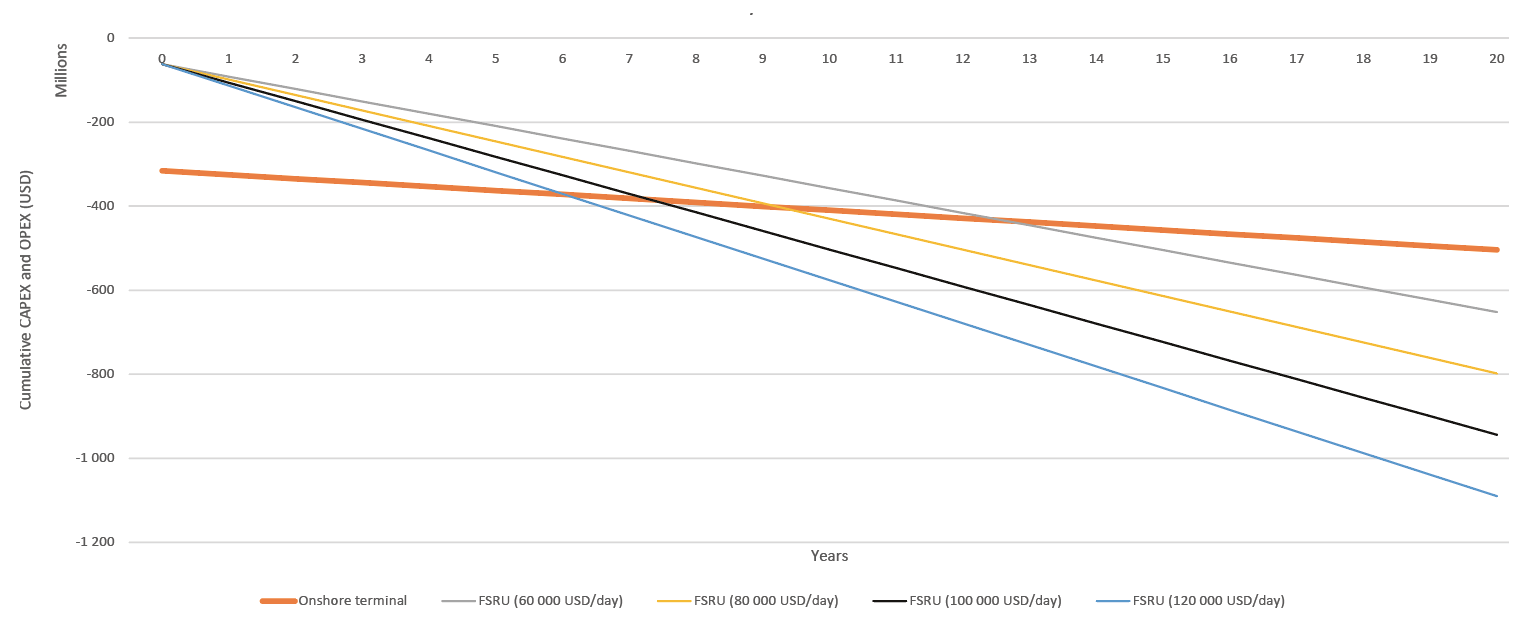

Studying the CAPEX and OPEX (see Figure 4) shows the cumulative cost over a 20-year period (assumed project lifetime) with various technologies. As can be seen from the graph, the breakeven is about six to seven years for FSRUs versus land-based terminals. (Figure 4)

What is interesting is combining an FSU (and also using the FSU as a carrier) with an FSRB that is used as a buffer storage while the FSU is on voyage. This is a good concept, since you have the regasification on board the FSRB and the concept is easily deployable for other locations. This can also be used as an intermediate solution during the construction of a permanent asset.

By adding a small power plant to the concept, we conveniently solve the boil-off gas management during low send-out periods or seasonal periods by generating electricity for the grid. The waste heat from the power plant cooling system can be used for

LNG evaporation, e.g., increasing the overall efficiency of the installation. (Figure 5)

Fig. 4 - Lifecycle cost comparison of FSRU, FSU and land-based terminal

Fig. 5 - Concepts

How to select technology

How does one make the selection for an LNG terminal technology? In general, one can say if the project lifetime is more than 10 years, it is more economical to use a land-based solution. Other selection criteria would be the need for fuel diversity, permanent asset and operational availability/reliability and financing.

The storage volumes and regasification volumes of land-based solutions can also more easily be expanded if needed, with the assumption that land area will be available.