The technology behind Inert Gas Systems (IGS) is mature and well-proven, and Wärtsilä has long been a market leader in the development, design, manufacture, and servicing of advanced IGS solutions. SAACKE is the inventor of Gas Combustion Unit (GCU) technology, and a specialist in combustion systems for seagoing vessels. Together, these two industry giants can improve system performance for customers and help the entire gas value chain to run a little smoother.

The recently signed strategic partnership agreement between Wärtsilä and SAACKE is likely to deliver benefits, both to the two companies themselves and, more importantly, to their customers. By working together, they can offer greater technology capability, notable cost savings, improved services, and easier procurement procedures. The cooperation will also add value for the market in general since it will encourage technical developments.

A history of firsts

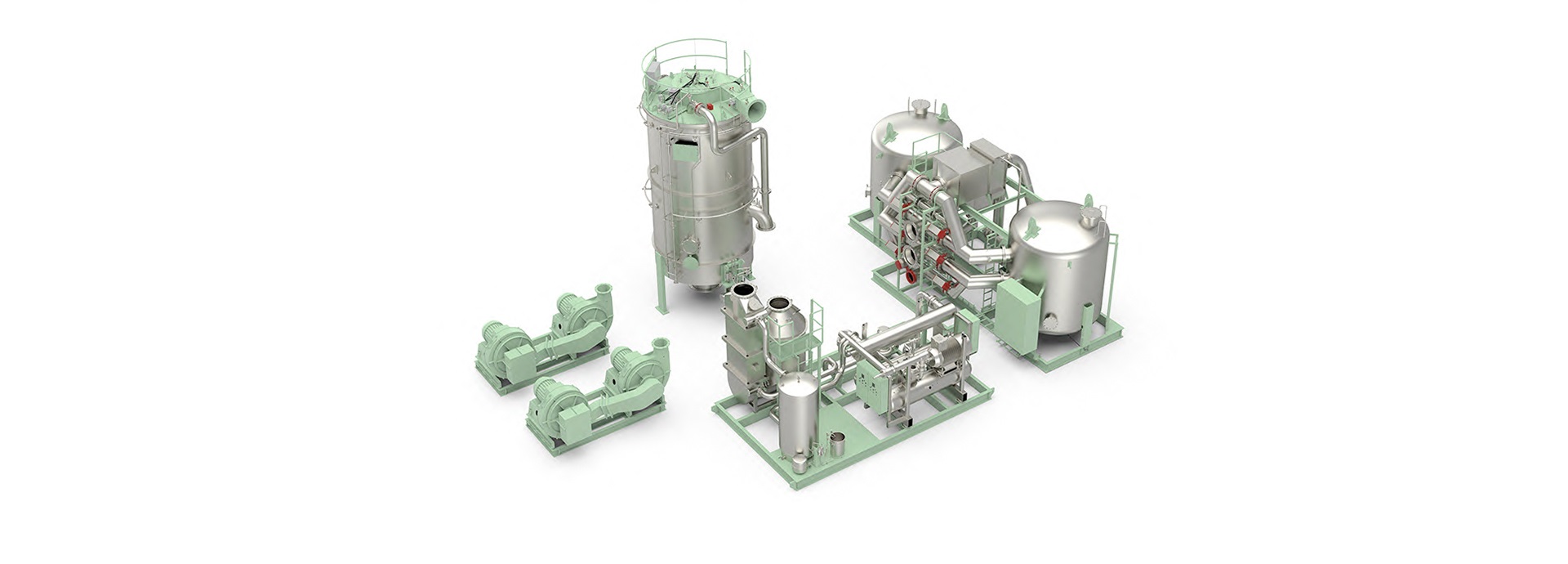

Inert Gas Systems are vitally important to the safe operation of oil tankers and offshore plants. For vessels transporting hydrocarbon-based cargo, Inert gas is utilized to secure an oxygen content below 5% of the remaining air/gas volume of the cargo tanks. By reducing the oxygen content to 5%, the oxygen content is too low for any ignition of the air/gas volume of the tank. Not surprisingly, an Inert gas system is today mandatory for oil, products and chemical tankers.

Wärtsilä has long been a pioneer in the development of Inert Gas Systems. The company has an impressive track record in introducing technical innovations that raise efficiency levels and improve safety. It’s extensive history of industry firsts starts with the fact that Wärtsilä was the first company to actually manufacture and install an IGS.

From this game-changing beginning, Wärtsilä went on to become the first company to introduce a series of technical innovations and system improvements that have become standard features of modern IG systems. As Terje Steingrimsen, Sales Manager, Inert Gas Systems in Gas Solutions explains: “We are a world leader in this field with a reference list of more than 2500 vessels operating with our inert gas systems installed. This is because, over the years, we have not only created, developed, and improved the systems, but at the same time we have developed strong customer relationships, we have integrated the products and services, and our global capability is unmatched. It’s not just the product, it’s the entire package that makes our offering so strong.”

Terje Steingrimsen, Sales Manager, Inert Gas Systems in Gas Solutions

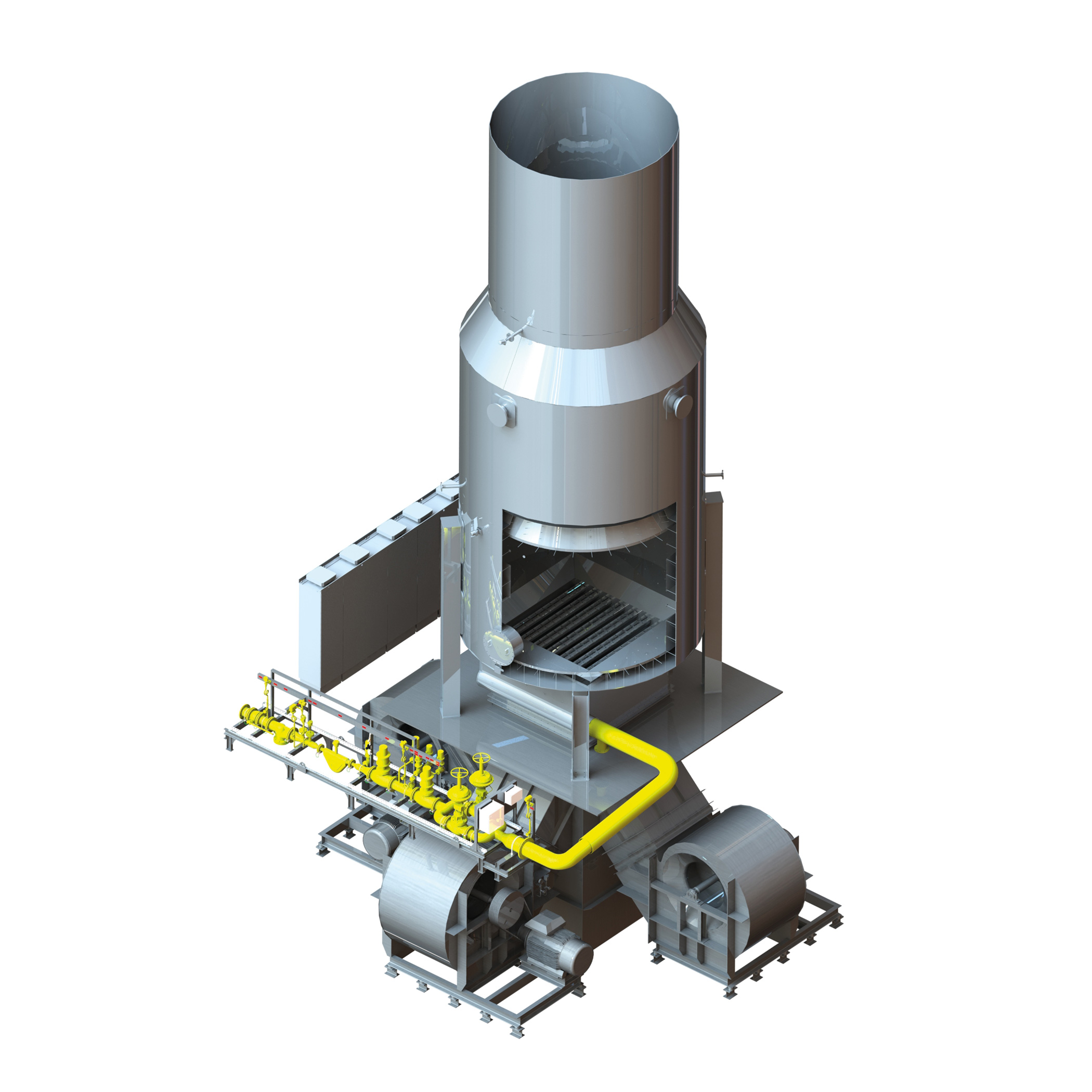

A specialist in combustion systems

Germany-based SAACKE is the inventor of Gas Combustion Unit (GCU) technology. GCUs are used to support the safe marine transportation of liquefied natural gas (LNG) by providing a reliable and secure method for burning the excess boil-off gas from the LNG cargo tanks. Apart from being a specialist in combustion systems, the company has a broad portfolio that also includes boiler plants and systems, as well as exhaust gas economizers. SAACKE’s global reach serves seagoing vessels, offshore installations, and LNG tankers.

“We have been involved in combustion technology for more than 90 years, and we offer highly efficient, reliable combustion plants with low levels of emissions. Our agreement with Wärtsilä extends our long-standing cooperation to a strategic partnership. This will deliver value to our customers and will improve the market position for both companies,” said Peter Breidenich, Director of Marine Systems at SAACKE.

Karsten Kroschel, Head of Sales Marine Systems, SAACKE agrees with this prediction: “One big area of benefit will be our mutual focus on the safety aspects of IGS and GCU systems. By working together, we can improve system performance in general, as well as taking a big picture overview of safety and integrated system issues to achieve advanced technical solutions. We will also be able to offer customers both separate and combined systems.”

Karsten Kroschel, Head of Sales Marine Systems, SAACKE

The agreement between Wärtsilä and SAACKE will expand and strengthen the two companies’ offering and will allow them to supply a comprehensive range of leading technology solutions to shipyards and ship owners. Wärtsilä will be able to offer its customers SAACKE’s boilers, exhaust gas economizers and air-cooled GCUs, while in addition to its Inert Gas Systems and combined Inert Gas and Combustion Units, Wärtsilä will also make its Flue Gas system available to SAACKE.

The Flue Gas system, which is primarily used on crude oil tankers, washes and cools the boiler flue gas and delivers it to the cargo tanks during cargo unloading and tank washing. As the flue gas already contains less than five percent oxygen, no further treatment is necessary. Customers will, therefore, be able to order both a boiler and a Flue Gas system as a single delivery, which has obvious benefits in terms of cost and system integration.

Meeting developing market demand

There is a growing global demand for LNG, which in addition to its establishment as a viable marine fuel, is increasingly being used in energy and industrial applications. The number of LNG Carrier vessels and LNG Bunker vessels on the seas is, therefore, growing along with this rise in demand.

At the same time, the market for liquefied petroleum gas (LPG) is also expected to remain strong during the coming years. This also means more LPG Carrier vessels being required. The joint offering of Wärtsilä and SAACKE targets these markets, thereby providing tanker vessel owners with a stronger and more competitive joint vendor. Having single integrated systems available from two such highly respected market leaders will inevitably increase efficiency levels and make the entire flow, from product procurement to system installation and to operational performance, that much more cost-effective and optimal.

Mechanical chains can get rusty and weak if not oiled. Value chains should not remain stagnant either, and to avoid the individual links from becoming weaker, constant upgrading, along with the introduction of better integration and improved flexibility, is an ongoing necessity. For the gas value chain, the partnership between Wärtsilä and SAACKE promises to provide some important lubrication to this chain, and delivery of a smoother flow of practical solutions.