The new Shuttle Tanker concept developed by the world’s largest provider of shuttle tanker services, TEEKAY, in close cooperation with Wärtsilä, will offer a new level of ecological and economical solutions by using Wärtsilä’s high-quality equipment and systems in innovative ways. Find out how this has reshaped the business of the industry.

It is raining innovations in Wärtsilä. The new Shuttle Tanker concept allows tankers to operate both on Liquefied Natural Gas (LNG), as the primary fuel, and Volatile Organic Compounds (VOC) – which is the environmentally harmful gas evaporating from the oil cargo tanks – as secondary fuel.

The new innovative solution aims to reduce annual emissions of CO2 equivalents by up to 42% compared to conventional shuttle tanker. The reduction equals the emissions from 22,000 cars per vessel per year.

The main task for a shuttle tanker is to transport oil from offshore fields to land-based oil terminals. As shuttle tankers operate in offshore conditions, these vessels are the most advanced merchant vessels with unique varieties in operation modes including loading in Dynamic Positioning (DP) condition, transit in laden, unloading and ballast conditions.

All of these operating modes have their own requirements, but traditionally these requirements have led to equipment installed on board not being used efficiently in the various operation modes.

The new Shuttle Tanker will have the following three features compared with a conventional shuttle tanker:

Reduced emissions: VOC emissions from the cargo will be eliminated, the NOx from the engine exhaust will be reduced by 84% which is well below IMO Tier 3 levels, while the SOx emissions will be practically eliminated, and finally the particles will be reduced by more than 96%, thus resulting in an astonishing reduction of emissions.

Operation flexibilities: an efficient use of the installed machinery and propulsion systems in the vessel secures an unmatched manoeuvring capability while the built-in system redundancies ensure an inherent system robustness when managing unexpected events.

Improved economics: 22% reduction in total fuel consumption and with the use VOC as fuel, resulting in considerable reduction in bunkering needs, and combined with fewer running hours hence lower maintenance costs for machinery.

Reduced emissions

During operation, conventional shuttle tanker design has high levels of emissions, mainly from the emissions of VOC to the atmosphere during loading, storage, and transportation of crude oil. For instance, the storage and loading of crude oil onto ships are responsible for more than 50% of Norway’s VOC emissions. The Norwegian authorities have thus implemented stringent emission reduction regulations for all shuttle tankers loading crude oil from offshore processing platforms located in the Norwegian continental shelf.

The loading operations take place when crude oil is loaded to the Shuttle Tanker directly via a loading hose connected to a Floating Production Storage Offshore (FPSO) unit, fixed platform or via a loading buoy. This operation can take place in harsh environments and with difficult sea stages. The crude oil need to be loaded with high transfer speed to ensure predictability in weather conditions throughout the DP operation.

During the offshore crude oil loading, the VOCs are emerging from the crude oil cargo tanks and must be captured by a VOC recovery plant, avoiding harmful emissions to the atmosphere

Wärtsilä has long experience in developing VOC recovery plants that can satisfy the requirements from the Norwegian authorities. With these experiences, Wärtsilä has now designed a new generation of VOC recovery plant that will satisfy also the more stringent authority requirements expected from 2030.

The Wärtsilä VOC recovery plant uses compression and cooling phases to liquefy the heavier hydrocarbons to Liquid VOC (LVOC) that is stored in a tank on the deck of the vessel.

The lighter hydrocarbons that are not liquefied, referred to as Surplus VOC (SVOC), which mainly consists of methane gas, will be burnt in a gas turbine for electricity generation, chosen because of the two times better efficiency than the traditional use of boiler with steam generator.

From a typical North Sea platform installation, each crude oil loading of a cargo size of 850,000 bbls, will recover 100 tonnes of LVOC and 10 tonnes of SVOC. By avoiding these amounts of VOC escaping into the atmosphere, the yearly reduction of emission goes from 43,000 to 25,000 tonnes of CO2, i.e., a reduction of 42%, assuming around 32 loadings per year.

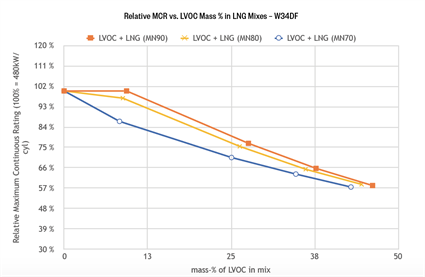

Fig. 1 - Relative MCR vs. LVOC Mass % in LNG Mixes – W34DF

Use of LNG and LVOC as fuel for engine

Today’s shuttle tankers are equipped with direct propelled 2-stroke diesel engines running on heavy fuel oil (HFO) or marine gas oil (MGO) and the recovered LVOC has so far been considered as a waste product. The 2-stroke engines are mainly used for propulsion during transit, and the 4-stroke auxiliary plant is providing power for the extensive thruster system used during DP operation.

With an average of 100 tonnes of recovered LVOC per loading, the recovered amount could represent up to 30% the total fuel consumption of the Shuttle Tanker should we be able to use the LVOC as fuel.

TEEKAY has therefore replaced the conventional 2- and 4-stroke engine configuration with fully electric propulsion with generator sets driven by Wärtsilä 4-stroke dual-fuel (DF) engines.

With electric main propulsion motors and 4-stroke DF generating sets as the only power plant onboard the vessel, flexibility and overlapping functionality is achieved. This power distribution concept is part of Wärtsilä Low Loss Hybrid concept reducing the total installed power on board from 26 to 23 MW with further reductions in fuel consumption and resulting in an increased overall efficiency of the vessel.

To achieve full SECA and NECA compliance, the new Shuttle Tanker will be further equipped with Wärtsilä LNGPac to enable operation in gas mode throughout the shuttle tanker operation with LNG as primary fuel for the engine.

With both LNG and LVOC onboard, Wärtsilä started to develop and performed testing of the possibility of mixing LNG with LVOC in gas form for potential valuable fuel for the engine.

LVOC comprises heavier gas hydrocarbons such as propane and butane that have relatively low methane number (MN) of 25, making them less suitable as fuel for our gas engines (to avoid knocking). By mixing the LVOC with LNG with an MN between 70 and 90, we will achieve an acceptable MN for the gas engine at any required power. Depending on the MN of LNG the engines will run a maximum continuous rating (MCR) less than 100% due to the de-rating mode. This de-rating mode is fully acceptable due to the operational flexibility built into the new Shuttle Tanker concept. (Figure 1)

Utilising LNG as the primary fuel and LVOC as secondary fuel, the new Shuttle Tanker enables the utilisation of 100% of the recovered LVOC as fuel for electric power generation. (Figure 2)

Fig. 2 - With an average fuel consumption of 8750 tonnes per year, 3200 tonnes will be generated and used onboard as LVOC.

Operational flexibility

The power distribution system will be based on the Wärtsilä Low Loss Hybrid (LLH) system using batteries for further fuel savings, peak load shaving and added overall system redundancy.

Wärtsilä LLH does not only offer the highest efficiency over all electrical components, but a great benefit comes from its superior capability to minimise the impact of a failure during DP operation. In addition to the required trial speed of the vessel, the size and functionality of the power plant is determined from the power requirement in DP condition. While a traditional electrical distribution system could lose more than 50% of installed power and several thrusters, the LLH will lose only 25% of the installed power and not more than one thruster.

Thanks to the LLH system, the system efficiency is improved and together with electric propulsion, the required total mechanical installed power will be reduced by 14%, which will improve overall fuel performance compared with traditional power distribution concepts.

As a result of the new Shuttle Tanker concept, the total energy consumption will go from 110 GWh to 75 GWh per year compared to a traditional shuttle tanker.

With increased efficiency, we will also improve the DP (manoeuvring) capability. A conventional system will use 60% of thruster power, whereas in LLC concept only 40% will be used, thus giving the master a much better manoeuvring capability.

Moreover, the LLH electric equipment room is more compact compared to a conventional electric room. The Shuttle Tanker power distribution system utilises a Low Voltage arrangement also with excess of 23 MW of installed power, which will again have a large benefit for the crew on board.

When installing batteries on board, the vessel has a hybrid energy system that will continuously support the dynamic capacity of the energy production system and, through the stored energy of the batteries, enable engines to operate in a load area where fuel consumption is optimal. The batteries will handle the dynamic load variations and the engines will get a stable load and therefore could operate in a higher load area without risking the startup of additional generators due to transient load variations. The New Shuttle Tanker is the first ship of this size utilising batteries for improving efficiency during transit operation.

For crude oil offloading operations at the onshore terminals, Wärtsilä can supply either electric-driven pumps for pump room installation, or electric-driven deep well cargo and ballast pumps that enable a distributed pump solution, eliminating the need for a separate pump room and interconnecting pipelines in the cargo holds.

The space gained from eliminating the pump room can be used either to increase the cargo capacity or to shorten the engine room with a shorter hull, giving lower building cost and better DP capability thanks to the leaner side profile.

With the efficient and environmentally friendly electric power plant installed on board the vessel, electrical-driven pumps for cargo off loading and ballast are utilised in the most efficient way.

In connection with ballast pumps, Wärtsilä can supply its Ballast Water Management System (BWMS) named AQUARIUS® EC. It uses an in-situ chlorine generation technology known as electro-chlorination (EC). AQUARIUS® EC is a modularly designed BWMS. The system is installed in a bypass loop to the main ballast line to provide a safe, flexible and economical process for the treatment of ballast water and eradication of aquatic invasive species.

Improved economics

The new Shuttle Tanker concept represents an absolute game-changer for the shuttle tanker sector. To put it in simple terms, the concept enables shuttle tankers to travel from the oil fields on its own waste gas rather than releasing it in the atmosphere. Both emissions and bunkering requirements will be considerably reduced and the chosen propulsion solution will increase overall efficiency compared with conventional systems.

With this concept, the overall running hours will be lower, which will mean lower maintenance costs for machinery.

Wärtsilä is also ready to support and provide active assistance during the operation of the new Shuttle Tanker vessels, to accomplish a total life-cycle solution to the owner. Such support and assistance will comprise both training of the crew and the officers for the equipment and the systems together with varied technical and operational real-time online support and monitoring. Such operational follow-up directly with the owner is crucial to ensure that the vessel achieves the objectives set for the new Shuttle Tanker in respect to emission reduction, fuel efficiency and with operational flexibility.

These benefits have been made possible with Wärtsilä’s advanced technology and through integration capabilities between different business segments in Wärtsilä supplying the various equipment and systems.

The new Shuttle Tanker is the first ship of this size utilising batteries for improving efficiency.

Market potential

TEEKAY has contracted two firm and two options of the new Shuttle Tanker vessel at Samsung in Korea, all based on Wärtsilä’s high-quality equipment and systems in this new and innovative concept solution.

We estimate that half of all offshore oil production in Norway and the UK will be transported to land using shuttle tankers. About 40% of this existing tanker fleet is ready for replacement due to the 20-year age limitation for new shuttle tankers.

We see an exciting time ahead for similar contracts in the near future for this ecological and economical Shuttle Tanker concept developed in cooperation with TEEKAY and Wärtsilä.