When Wärtsilä’s Propulsion Condition Monitoring Service (PCMS) was launched in 2010, it was first of its kind. The latest version of the service is a state-of-the-art tool designed to facilitate preventive maintenance and help maximise uptime for Wärtsilä’s customers across the globe. Here’s a closer look at the offering.

The Propulsion Condition Monitoring Service (PCMS) is Wärtsilä’s Condition-Based Maintenance (CBM) solution for propulsion equipment. By carrying out measurements of critical parameters such as vibrations and oil condition, as well as operational parameters including steering angles, rotational speeds, and pitch angles, the Wärtsilä PCMS provides customers with real-time advice and periodic reports on the condition of their machinery, as well as crucial information for maintenance planning.

Since its launch in 2010, the Wärtsilä PCMS has been successfully installed on hundreds of applications. Late last year, Wärtsilä released a new, more cost-effective version of the solution, based on third-party hardware, featuring even higher quality vibration data and reduced on-site maintenance requirements.

Why do customers need the Wärtsilä PCMS?

The PCMS enables Wärtsilä customers to improve the availability, reliability and profitability of their vessels while reducing risks and maintenance costs. By monitoring and analysing the parameters that affect the condition of the propulsion equipment, Wärtsilä’s experts can predict an upcoming failure and also advise customers on the best action to take to mitigate its impact.

The Wärtsilä employees responsible for analysing the data produced by the PCMS have extensive experience and in-depth knowledge of both the propulsion equipment itself and the operational context in which it is used. Once a problem is detected, Wärtsilä will not only make the customer aware of the issue but also provide expert advice on how to address the problem and minimise operational disturbances. For example, this might involve reducing the load on the thruster in order to complete an on-going voyage and scheduling maintenance once the vessel reaches a port.

To make optimal use of the PCMS, and other CBM equipment of this kind, they are best combined with a long-term Wärtsilä service agreement. This allows Wärtsilä not only to detect a possible future failure but also to schedule and carry out the required maintenance in a way that minimises stoppages and costs and maximises uptime and operational efficiency for the customer.

Reliability of Wärtsilä PCMS

Wärtsilä is recognised as a Condition Monitoring service supplier by four of the world’s major classification societies: The American Bureau of Shipping, Lloyd’s Register, China Classification Society (CCS) and DNV-GL. These societies have acknowledged that the Wärtsilä PCMS can determine the condition of propulsion equipment and enable the extension of required visual internal inspections.

The exceptional reliability of the equipment enables Wärtsilä to carry out optimised maintenance, whereby service is only carried out when necessary and not according to a fixed, time-based schedule. The result is significantly extended service intervals and the reduction of both service-related costs and downtime. For example, a thruster may only require two overhauls over a 15-year lifecycle, instead of three.

What’s new?

Released in December 2018, the new version of PCMS, which is based on third-party condition monitoring hardware systems, is significantly more cost efficient than the previous version of the solution. Customers who sign up for the new PCMS will obtain even better quality vibration data. Moreover, the new system requires fewer software updates and less maintenance, thereby significantly reducing the need for on-site service. The PCMS can be installed on all kinds of vessels and is available for both Wärtsilä and non-Wärtsilä propulsion equipment including transverse thrusters, steerable thrusters, electric pods, controllable pitch propellers, gearboxes, and water jets. Going forward, Wärtsilä intends to expand the scope of their condition monitoring services to include all types of rotating equipment such as pumps, generators, electric motors, and compressors. One of the major benefits of the new PCMS is that, unlike the previous version, which could only be applied to propulsion equipment, the new version has made it possible for these types of generic rotating equipment to be included in the scope.

How does the Wärtsilä PCMS work?

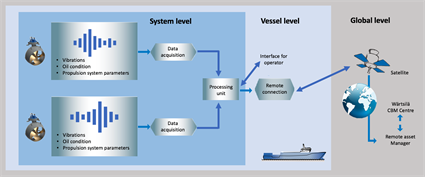

Figure 1 above shows the general layout of a vessel with two propulsors, which are both equipped with PCMS sensors and connected to one PCMS cabinet. The cabinet acquires and processes data from sensor readings and the propulsion control system according to the set operational parameters.

The data is processed on board and sent to an assigned technical expert at Wärtsilä. A dashboard (an optional feature) installed on the bridge or in the engine control room allows the operator to monitor the condition of the vessel’s propulsion machinery using both real-time and trend data with advice available in case of irregularities.

The central PCMS server continuously processes the data and sends an immediate alert to Wärtsilä’s certified experts if an issue arises. If daily follow-up is included in the PCMS agreement, a thorough analysis will be carried out the same day and, if abnormalities requiring immediate attention are detected, the CBM expert will inform the operator.

All Wärtsilä PCMS customers receive a periodic report detailing the latest findings and recommendations from their propulsion monitoring. The report also describes the condition of the propulsion equipment, the recommended maintenance interval and advice for how best to keep the equipment in optimal condition.

The PCMS and Artificial Intelligence – what does the future hold?

The CBM systems we know today are based on sensors and techniques such as trend- and vibration analysis. While they are effective, they rely on the engineering rules and their application is limited to specific failure modes. In short, every issue that needs to be monitored requires an engineer to design a rule to detect it.

Looking to the future, advancements in Artificial Intelligence (AI) and automation stand greatly to enhance the sophistication of CBM systems such as the PCMS. With the advent of Machine Learning (ML) technologies such as Google’s TensorFlow, the world of CBM stands before a major paradigm shift. In the coming years, there is reason to believe that these systems will come to rely less on the rigid rules of engineering and more on the flexibility offered by ML algorithms. Holistic solutions will replace point solutions and periodic reports will be a thing of the past, as real-time reporting becomes the new normal. Backed by the enormous processing power of AI, the ML algorithms will immediately and automatically analyse all incoming data, enabling human experts to dedicate less time to crunching numbers and troubleshooting, and more time to supporting customers, and delivering support and value-adding optimisations.

In short, AI will make us more proactive, helping us detect and solve problems more quickly and accurately. Customers of the future will be able to expect enhanced levels of service, more precise prediction of problems and faster planning and execution of preventive maintenance. The work that currently has to be carried out by humans will eventually only need to be supervised by humans, allowing Wärtsilä to provide a faster, more reliable service than ever before.

The Wärtsilä PCMS enables ship owners and operators to:

- Base operational decisions on the actual condition of their equipment

- Maximise the availability of their vessel by performing overhauls only when needed

- Reduce the likelihood of breakdowns by being proactively informed of faults

- Increase the lifetime of equipment and preserve its condition by obtaining feedback on the factors that cause excess wear and failures

- Reduce the total cost of ownership and maximise profitability