Delphis’s ice-classed container ships were fitted with Wärtsilä propellers and propeller caps, improving energy efficiency by 4%. Delphis, a division of CMB Group, specialises in mid-size container ships focused on regional trade. They approached Wärtsilä with the goal of improving the fuel efficiency of part of their fleet.

“The main goal we had was to increase the energy efficiency of the vessels considering their operating profile,” says Bart Rombouts, Technical Director of CMB. “We wanted a new propeller system to increase energy efficiency.”

Shipowners and operators are demanding increasing efficiency both for environmental and economic reasons. New ships are ultra-efficient compared to their predecessors, but it is also possible to remarkably improve efficiency on older vessels

with the right upgrades. Delphis wanted to enhance fuel efficiency for six of their ships which had been chartered by one of Europe’s biggest container ship and supply vessel operators.

“Delphis chose Wärtsilä to provide

and install new propellers,” says Arnold Feber, Senior Business Development & Sales Manager at Wärtsilä. “However, it was only six or seven months until the ships went into dry dock, so there was extreme time pressure to

get it done right.”

On average, the scheduled drydock duration for each ship was twelve days, including the installation of a new propeller and propeller cap. It was important to minimise the time in dry dock so the ships could get

back in operation and realise the benefits of the new equipment.

“It is amazing that no time was lost in dry dock,” says Rombouts. “Even with a changing schedule it was all completed on time.”

Significant efficiency gains

“The new propellers were able to improve efficiency by 1.5% while the EnergoProFin propeller cap improved efficiency by 2.5%, giving a total improvement of 4%,” says Joost Vos, Business Development Manager at Wärtsilä.

A 4% improvement in energy efficiency is massive on this scale, saving 458 metric tonnes of fuel annually for each ship. The reduction in fuel use also lowers greenhouse gas emissions.

This

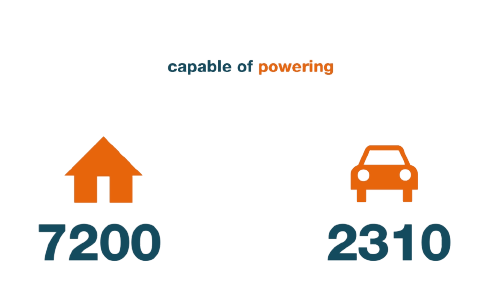

is the same amount of energy to power almost 1,200 homes or 385 mid-sized cars annually. In total, Wärtsilä’s energy efficiency solutions on the six ships saves Delphis 2,748 tonnes of fuel each year, which could power 7,200 homes

or 2,310 cars.

“We chose Wärtsilä for technical and economic reasons. We are able to monitor the efficiency gains with our in-house developed performance monitoring software and, with the new propellers and propeller caps, we have achieved 4% savings. This is a very significant improvement in efficiency.

- Bart Rombouts, Technical Director of CMB

Complete solutions

The Wärtsilä EnergoProfin also reduces underwater noise and should be maintenance-free during their lifetime.

“Another important point is that Delphis required the propellers to be strong enough to withstand ice,”

Feber says. “The Wärtsilä monobloc propellers worked well with Delphis’s ice-classed ships.”

Delphis has one of the largest ice-class fleets in the world. The ice-class compliant solutions virtually future-proof

Delphis’s vessels for the rest of their lifetime.

"CMB has a been a good partner with Wärtsilä and in fact, many of the Delphis ships have Wärtsilä two-stroke engines,” says Vos. “Since Wärtsilä

had the complete drive train we had more information to optimise the propellers and improve efficiency during this project.”

This was on point which Rombouts emphasised: Wärtsilä used CMB’s data to make the best

solution for their new propulsion system. This could also be used for other segments of their fleet, such as tankers.

“We have had good cooperation with Wärtsilä, and in fact have used them for other solutions, such

as engines and ballast water treatment systems,” says Rombouts. “We will definitely check with Wärtsilä when we retrofit other ships in our fleet for energy efficiency solutions.”