"At the state-of-the-art premises of Wärtsilä’s Fuel Laboratory Services, researchers explore novel fuel flexibility options, such as reclaiming the fuel content of plastics."

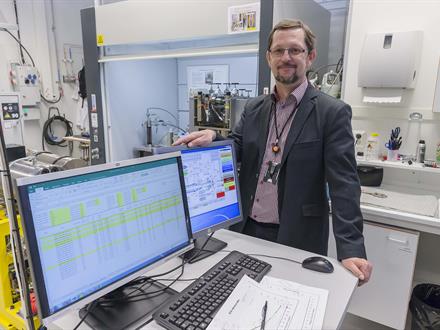

The small coastal city of Vaasa in western Finland, best known for its ferries to Sweden and a popular family waterpark, seems like an unlikely location for a specialist scientific laboratory. But the quiet and important work proceeding here has far-reaching results affecting everyday life. This is the hub of Wärtsilä’s Fuel Laboratory Services, part of the Energy Solutions department and an expert pioneer in gaseous and liquid fuel know-how.

If you are wondering how this could possibly affect your life, consider the very topical and increasingly urgent issue of plastic recycling. There is a pressing global need for innovative solutions to reduce the use of plastics, especially to halt the disruption caused by plastic waste to vulnerable ocean ecosystems. New technology that reclaims the fuel content of plastics is gaining credibility as one solution to this challenge, and the Fuel Laboratory is playing a role in its development.

“Our experiments deal with the kinds of plastic that can’t be re-used anymore,” says Senior Development Manager Olai Lagus, who is the lab’s customer contact related to fuel chemistry and one of a team of nine lab staff in the Vaasa area. “If a plastic is contaminated with other kinds of plastic, there aren’t any other ways to recycle it. Another similar project we are involved in is with a customer in Cyprus who is interested in the potential for reclaiming fuel from car tyres. We have been carrying out the testing and piloting for this customer.”

State-of-the-art competence

The kind of fuel flexibility explored by the lab, says Tommi Rintamäki, General Manager, Fuel Laboratory Services, is a fundamental part of Wärtsilä’s Smart Power Generation value proposition.

“The lab was established in 2009 as part of our Power Plant Technology activities,” he explains. “The daily work relates mainly to sales and after-sales support on various liquid or gaseous fuel-related questions. Over the years, the lab staff have developed a state-of-the-art competence in chemical and combustion analyses related to engine power plants. The work involves various combustion and fuel analyses rather than engine testing as such.”

The lab’s portfolio lists several customer cases involving fuel oil manufactured from waste tyres and plastic, and it includes a range of locations and other fuel industry applications.

“Recently, a customer in Mauritania was suffering from operational problems which were identified with our support to be caused by a heavy fuel oil containing too many impurities resulting in filter clogging,” says Rintamäki. “Right now, in Japan there is a lot of focus on liquid biofuel development, in relation to which dozens of fuel analyses have been carried out in our laboratory to support the end customer’s fuel supplier selection.”

Supporting decision-making

Lagus is keen to point out the advantages offered by the Fuel Laboratory compared with other industrial labs. “In Wärtsilä’s case, we are able to look into the reasons behind the test results and offer conclusions about how to proceed,” he says. “From a standard lab, you usually just get the numbers and results, but we have developed that extra ability to draw conclusions. If we observe a phenomenon, we have the capacity to look into it and go further to help solve a problem. This advantage is definitely a competitive edge.”

“Much of our daily work is today channelled via the sales and after-sales organisation to serve end-customer needs,” says Rintamäki. “We are starting to create more direct business contacts with existing and potential new customers.

.tmb-thumb425.jpg?Culture=en&sfvrsn=3a728c45_2)

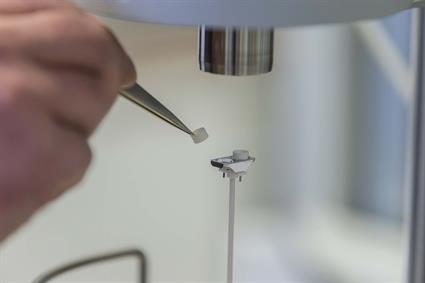

An example of the lab’s latest novel equipment is a Rapid Compression Machine, developed to support gaseous fuel research in the most effective way.

“Using this equipment, we can, in just some hours, mix fuel gas according to customer specifications, test the combustion and give a ‘go – no go’ answer to the gas in question,” says Rintamäki. “This innovation is another significant competitive edge we have over our competitors.”

Service orientation

The emphasis of Wärtsilä’s Fuel Laboratory Services will be more on the ‘services’ aspect in the future, as the lab’s mission moves away from R&D-orientated activities towards sales and helping to provide answers to customers with fuel-related questions.

“It remains to be seen to what extent we might grow in the coming years, but our biggest role within Wärtsilä is to contribute to the company’s special expertise in general,” says Rintamäki, who moved into the GM post in spring 2017. “It’s a very exciting opportunity for me personally as well as for the company, but we are still at an early phase so we’ll see how our role evolves. But we are fine-tuning our strategy to guide our focus on research in coming years.”